Description

ABB 3BHB030310R0001 GVC736CE101

I. Product Overview

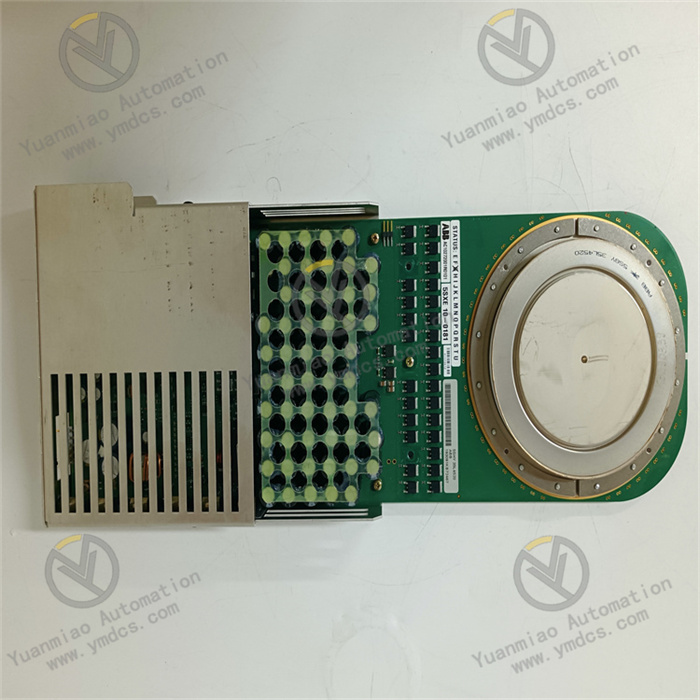

(1) 3BHB030310R0001

3BHB030310R0001 is a grid circuit breaker control unit used in medium and high voltage drive systems. It plays a pivotal role in the power control and protection 环节 of the entire drive system. Its core function is to efficiently manage the electrical connection between the power supply and the drive equipment. By precisely controlling the closing and opening operations of the circuit breaker, it achieves the tasks of system startup, stable operation, and grid isolation under fault protection conditions. With its excellent performance and reliable quality, this product is widely integrated into ABB's medium voltage inverter systems, such as the ACS6000 series, and becomes a key guarantee for the stable operation of the drive system.

(1) 3BHB030310R0001

3BHB030310R0001 is a grid circuit breaker control unit used in medium and high voltage drive systems. It plays a pivotal role in the power control and protection 环节 of the entire drive system. Its core function is to efficiently manage the electrical connection between the power supply and the drive equipment. By precisely controlling the closing and opening operations of the circuit breaker, it achieves the tasks of system startup, stable operation, and grid isolation under fault protection conditions. With its excellent performance and reliable quality, this product is widely integrated into ABB's medium voltage inverter systems, such as the ACS6000 series, and becomes a key guarantee for the stable operation of the drive system.

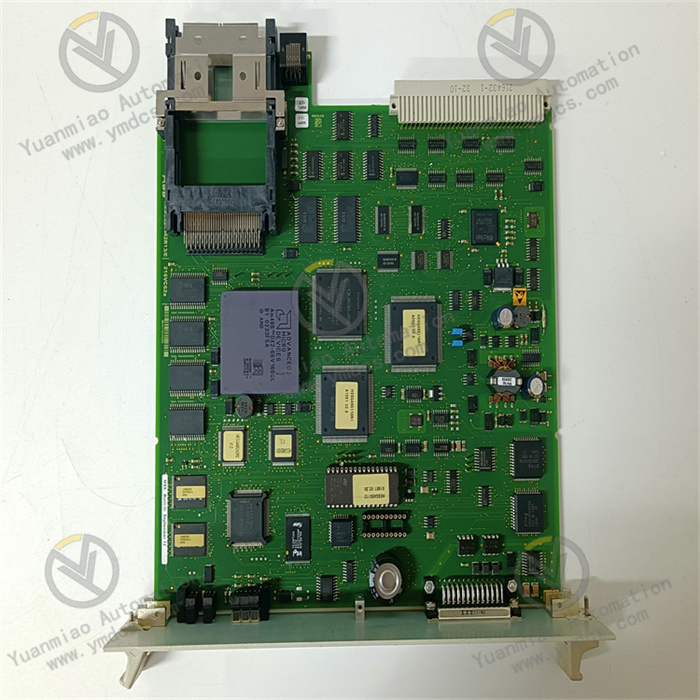

(2) GVC736CE101

GVC736CE101 belongs to ABB's 3BHE series. It is an industrial automation controller module specially designed to meet the needs of high-precision control and complex logic operations. It highly integrates advanced processors and a variety of interfaces, and can accurately realize the all-round control of various industrial equipment and production processes, providing a solid technical support for the industrial automation process. In the field of industrial automation and power control, the 3BHE series is famous for its excellent high performance and high reliability. As a member of this series, GVC736CE101 inherits the fine genes of the series and plays an irreplaceable role in many industrial scenarios.

GVC736CE101 belongs to ABB's 3BHE series. It is an industrial automation controller module specially designed to meet the needs of high-precision control and complex logic operations. It highly integrates advanced processors and a variety of interfaces, and can accurately realize the all-round control of various industrial equipment and production processes, providing a solid technical support for the industrial automation process. In the field of industrial automation and power control, the 3BHE series is famous for its excellent high performance and high reliability. As a member of this series, GVC736CE101 inherits the fine genes of the series and plays an irreplaceable role in many industrial scenarios.

II. Technical Parameters

(1) 3BHB030310R0001

Electrical Parameters

Control Voltage: Under normal circumstances, the control voltage of this module is 24V DC, but the specific value will be flexibly adjusted according to the actual needs of the supporting system. The stable control voltage input ensures that the module can run continuously and reliably, and accurately execute control commands.

Adaptive Voltage Level: This module is mainly applicable to 6kV / 11kV medium voltage systems, but the voltage level in actual applications will vary according to the specific configuration of the whole machine. In the medium voltage environment, it can efficiently control the grid circuit breaker to ensure the safe and stable operation of the system.

(1) 3BHB030310R0001

Electrical Parameters

Control Voltage: Under normal circumstances, the control voltage of this module is 24V DC, but the specific value will be flexibly adjusted according to the actual needs of the supporting system. The stable control voltage input ensures that the module can run continuously and reliably, and accurately execute control commands.

Adaptive Voltage Level: This module is mainly applicable to 6kV / 11kV medium voltage systems, but the voltage level in actual applications will vary according to the specific configuration of the whole machine. In the medium voltage environment, it can efficiently control the grid circuit breaker to ensure the safe and stable operation of the system.

Physical Parameters

Dimension Specifications: It is inferred from the existing data that its size is designed to be compact and reasonable, so as to be integrated into the cabinet or frequency conversion system, saving space for the overall system layout. Although the specific size is not clear yet, it is certain that it has been carefully optimized and can perfectly meet the installation requirements of various industrial equipment.

Installation Method: It adopts the modular design concept and has high installation flexibility. Whether in the initial installation stage of a new system or the upgrading and transformation process of an existing system, it can be easily integrated into the cabinet or frequency conversion system, which greatly improves the convenience of system construction and maintenance.

Dimension Specifications: It is inferred from the existing data that its size is designed to be compact and reasonable, so as to be integrated into the cabinet or frequency conversion system, saving space for the overall system layout. Although the specific size is not clear yet, it is certain that it has been carefully optimized and can perfectly meet the installation requirements of various industrial equipment.

Installation Method: It adopts the modular design concept and has high installation flexibility. Whether in the initial installation stage of a new system or the upgrading and transformation process of an existing system, it can be easily integrated into the cabinet or frequency conversion system, which greatly improves the convenience of system construction and maintenance.

Performance Parameters

Communication Capability: This module can realize seamless connection with ABB's control boards, such as PMI, GVC, etc., and has a status feedback function. Through efficient data communication, the operation status of the circuit breaker is fed back to the control system in real time, so that the operator can grasp the system situation in time and make accurate decisions.

Protection Performance: As a key control device on the grid input side, it can accurately control the connection and disconnection of the power supply. When the inverter system encounters abnormal conditions, it can quickly cut off the power supply, effectively protect the stable operation of the inverter system, and reduce the damage caused by faults to the system.

Communication Capability: This module can realize seamless connection with ABB's control boards, such as PMI, GVC, etc., and has a status feedback function. Through efficient data communication, the operation status of the circuit breaker is fed back to the control system in real time, so that the operator can grasp the system situation in time and make accurate decisions.

Protection Performance: As a key control device on the grid input side, it can accurately control the connection and disconnection of the power supply. When the inverter system encounters abnormal conditions, it can quickly cut off the power supply, effectively protect the stable operation of the inverter system, and reduce the damage caused by faults to the system.

(2) GVC736CE101

Electrical Parameters

Input Voltage: Its input voltage is 24V DC. The stable low-voltage input not only ensures the safe operation of the module, but also meets the general requirements of industrial automation equipment for power supply.

Electrical Parameters

Input Voltage: Its input voltage is 24V DC. The stable low-voltage input not only ensures the safe operation of the module, but also meets the general requirements of industrial automation equipment for power supply.

Physical Parameters

Dimension Specifications: The size of the module is 200mm × 150mm × 50mm. The compact design makes it easy to install in the industrial control cabinet with limited space without occupying too much space.

Operating and Storage Temperature Range: The operating temperature range is -40°C to +60°C, and the storage temperature range is -40°C to +85°C. Such a wide temperature adaptation range enables the module to work stably in various harsh industrial environments, whether in high-temperature smelting workshops or low-temperature cold storage environments, without affecting its performance.

Dimension Specifications: The size of the module is 200mm × 150mm × 50mm. The compact design makes it easy to install in the industrial control cabinet with limited space without occupying too much space.

Operating and Storage Temperature Range: The operating temperature range is -40°C to +60°C, and the storage temperature range is -40°C to +85°C. Such a wide temperature adaptation range enables the module to work stably in various harsh industrial environments, whether in high-temperature smelting workshops or low-temperature cold storage environments, without affecting its performance.

Performance Parameters

Communication Interfaces: Equipped with a variety of communication interfaces such as Ethernet, Modbus, Profibus, etc., it can conduct efficient data interaction with industrial equipment of different brands and types, realizing the interconnection and collaborative work of the system.

Control Accuracy and Computing Power: The integrated advanced processor endows the module with strong computing power and processing speed, which can quickly and accurately process complex control logic and realize high-precision control of industrial equipment and production processes. In industrial scenarios that require precise control of parameters such as flow, temperature, and pressure, it can complete tasks excellently, ensuring the stability of the production process and the consistency of product quality.

Communication Interfaces: Equipped with a variety of communication interfaces such as Ethernet, Modbus, Profibus, etc., it can conduct efficient data interaction with industrial equipment of different brands and types, realizing the interconnection and collaborative work of the system.

Control Accuracy and Computing Power: The integrated advanced processor endows the module with strong computing power and processing speed, which can quickly and accurately process complex control logic and realize high-precision control of industrial equipment and production processes. In industrial scenarios that require precise control of parameters such as flow, temperature, and pressure, it can complete tasks excellently, ensuring the stability of the production process and the consistency of product quality.

III. Functional Characteristics

(1) 3BHB030310R0001

Efficient Grid Connection Control

3BHB030310R0001 can quickly and accurately control the closing and opening actions of the circuit breaker. During system startup, it precisely controls the closing of the circuit breaker to ensure that the power supply can be safely and stably connected to the drive equipment, providing power support for the normal operation of the equipment. During the operation of the system, it monitors the grid and equipment status in real time. Once abnormal conditions such as overcurrent and overvoltage are detected, it immediately controls the circuit breaker to open and quickly cut off the power supply to protect the equipment from damage.

(1) 3BHB030310R0001

Efficient Grid Connection Control

3BHB030310R0001 can quickly and accurately control the closing and opening actions of the circuit breaker. During system startup, it precisely controls the closing of the circuit breaker to ensure that the power supply can be safely and stably connected to the drive equipment, providing power support for the normal operation of the equipment. During the operation of the system, it monitors the grid and equipment status in real time. Once abnormal conditions such as overcurrent and overvoltage are detected, it immediately controls the circuit breaker to open and quickly cut off the power supply to protect the equipment from damage.

For example, in the large motor drive system in the metallurgical industry, a large inrush current will be generated at the moment the motor starts. 3BHB030310R0001 can accurately control the closing time of the circuit breaker according to the current change, so as to avoid the adverse impact of the inrush current on the grid and equipment. During the operation of the motor, it continuously monitors parameters such as current and voltage, and timely opens the brake when abnormalities occur to ensure the safety of the motor and the entire drive system.

Good System Compatibility

Due to its modular design and support for standard communication protocols, it can seamlessly integrate with various ABB control boards and systems. In different industrial application scenarios, whether it is a simple single-machine drive system or a complex multi-machine linkage automatic production line, it can be easily adapted.

Due to its modular design and support for standard communication protocols, it can seamlessly integrate with various ABB control boards and systems. In different industrial application scenarios, whether it is a simple single-machine drive system or a complex multi-machine linkage automatic production line, it can be easily adapted.

Taking the high-voltage frequency conversion system of a cement production plant as an example, this module can work together with other ABB control equipment to complete the drive control of various large-scale equipment on the cement production line, such as crushers and mills. Through efficient communication and cooperation with other equipment, the automatic operation of the entire production line is realized, the production efficiency is improved, and the labor cost is reduced.

Reliable Fault Protection Function

It has a built-in perfect fault detection and protection mechanism, which can monitor its own operation status and relevant parameters of the power grid and equipment in real time. Once a potential fault is found, corresponding protection measures will be taken immediately, such as cutting off the power supply and sending out an alarm signal.

It has a built-in perfect fault detection and protection mechanism, which can monitor its own operation status and relevant parameters of the power grid and equipment in real time. Once a potential fault is found, corresponding protection measures will be taken immediately, such as cutting off the power supply and sending out an alarm signal.

For example, when it is detected that the abnormal fluctuation of the grid voltage exceeds the allowable range, the module will quickly control the circuit breaker to open to prevent excessive or too low voltage from damaging the equipment. At the same time, the fault information is fed back to the control system through the communication interface, so that maintenance personnel can check and handle it in time, shorten the equipment downtime, and improve the continuity of production.

(2) GVC736CE101

Strong Logic Operation and Control Capability

With an advanced processor, it can quickly process a large amount of input data and generate accurate control commands according to preset control logic and algorithms. In the industrial automation production line, it can realize complex control of equipment according to different production process requirements, such as multi-axis motion control and process control.

Strong Logic Operation and Control Capability

With an advanced processor, it can quickly process a large amount of input data and generate accurate control commands according to preset control logic and algorithms. In the industrial automation production line, it can realize complex control of equipment according to different production process requirements, such as multi-axis motion control and process control.

For example, in the automatic assembly workshop of automobile manufacturing, GVC736CE101 can precisely control the movement track, grasping force and assembly sequence of the robotic arm to ensure that auto parts can be assembled accurately. Through precise control of the production process, the quality of product assembly is improved, the defective rate is reduced, and the production efficiency of enterprises is enhanced.

Rich Communication and Data Interaction Functions

The configuration of multiple communication interfaces enables it to conduct high-speed and stable data transmission with on-site sensors, actuators, upper computers and other control systems. Through real-time collection of sensor data, such as data from temperature sensors and pressure sensors, the production process is monitored and analyzed in real time. At the same time, control commands are accurately sent to actuators, such as motors and valves, to realize precise control of equipment.

The configuration of multiple communication interfaces enables it to conduct high-speed and stable data transmission with on-site sensors, actuators, upper computers and other control systems. Through real-time collection of sensor data, such as data from temperature sensors and pressure sensors, the production process is monitored and analyzed in real time. At the same time, control commands are accurately sent to actuators, such as motors and valves, to realize precise control of equipment.

In the construction of smart factories, GVC736CE101 can communicate with the factory's central control system through the Ethernet interface, upload equipment operation data and receive production task instructions. It connects with various on-site equipment through Modbus or Profibus interfaces to realize the interconnection and intelligent management of the entire factory production system.

High Stability and Reliability

It adopts high-quality hardware components, advanced circuit design and optimized control algorithms to ensure stable operation in harsh industrial environments. In harsh conditions such as high temperature, high humidity and strong electromagnetic interference, it can still maintain precise control performance, reducing equipment failures and downtime.

It adopts high-quality hardware components, advanced circuit design and optimized control algorithms to ensure stable operation in harsh industrial environments. In harsh conditions such as high temperature, high humidity and strong electromagnetic interference, it can still maintain precise control performance, reducing equipment failures and downtime.

For example, in the chemical production workshop, there are a lot of corrosive gases and strong electromagnetic interference. GVC736CE101 can stably control the operation of various chemical equipment with its excellent stability and reliability, ensuring the safety and stability of the chemical production process. Its high reliability is also reflected in the accuracy and consistency of data processing, ensuring the reliability of data transmission and control command execution in the production process, and providing a strong guarantee for the safe production and efficient operation of enterprises.