Description

ABB PP881 3BSE092979R1

The ABB PP881 3BSE092979R1 is a touchscreen panel belonging to ABB's Panel 800 series and part of the Distributed Control System (DCS). It is widely used in various industries such as petroleum, chemical, metallurgy, cement, water treatment, construction, and machinery, etc., to achieve functions like process monitoring, operation control, and data display, providing an efficient and reliable human-machine interface for industrial automation systems.

Features and Advantages

Display and Interaction

- Equipped with a bright TFT/LED display featuring high-resolution graphics, delivering clear images and rich colors. Vector-based graphics combined with icon-based interfaces, navigation, and controls ensure easy operation and excellent operator interaction.

Programming and Engineering Design

- Programmed using the Panel Builder tool, which operates in a familiar Microsoft Windows environment with multi-language support, enabling fast, simple, and efficient engineering design. Applications can be directly simulated and run before using Panel Builder 800, facilitating debugging and testing.

Hardware Design

- Features a robust and lightweight die-cast, powder-coated aluminum enclosure. The front housing withstands 潮湿 (humid), dusty, and harsh environments, operating within a temperature range of -10°C to +60°C and up to 85% humidity, ensuring strong environmental adaptability and reliability.

Openness and Connectivity

- Based on an open architecture and technologies 附带 (included) with the .NET framework, it enables connection to multi-brand controllers and offers multiple connectivity options for local communication, expansion, remote access, etc., providing high flexibility and scalability.

Technical Parameters

Display Parameters

- For the PP883 model (same series as PP881, some parameters for reference): 12.1-inch display, 1280x800 pixel resolution, 400cd/m² brightness, touchscreen type, and resistive touch interaction.

Processor and Memory

- Uses an ARM9 (1GHz) processor, 1GB main memory, and a 2GB SSD external storage medium, with 1.5GB available for application storage.

Interfaces

- 2x Ethernet ports (10/100Base-T), 2x USB 2.0 ports (500mA), 1x RS-232 serial port, 1x RS-422/485 serial port, and an additional RS-485 serial port (only when COM2 is RS-485).

Power Supply

- Powered by +24VDC (voltage range 18-32VDC), with a power consumption of 28.8W.

Protection Rating

- Front panel: IP65, NEMA 4X/12, and UL Type 4X/12; rear panel: IP20.

Working Principle of ABB PP881 3BSE092979R1

1. Core Architecture and Processor

As a controller module from ABB (typically used in the AC800M series PLC), the PP881 is based on a high-performance microprocessor (such as ARM or PowerPC architecture) with a Real-Time Operating System (RTOS) to ensure fast response to industrial control tasks (instruction execution speed up to microsecond level). Its internal modular design integrates CPU, memory, communication interfaces, and power management units, supporting multitask parallel processing, such as logic operations, data acquisition, and communication scheduling.

2. Program Execution and Data Processing

- User Program Operation:

The module receives user-written control logic through programming software (such as ABB Control Builder M), following the IEC 61131-3 standard and supporting languages like Ladder Diagram (LD) and Structured Text (ST). Programs are stored in non-volatile memory (ROM/Flash) and loaded into Random Access Memory (RAM) during operation. - Cyclic Scanning Mechanism:

Adopts a periodic scanning approach, working in a three-step cycle of "input sampling → program execution → output refresh": - Input Sampling: Reads the status of connected I/O modules (e.g., digital and analog inputs) and stores them in the input image register.

- Program Execution: Processes input signals according to user logic and stores results in the output image register.

- Output Refresh: Drives field devices (e.g., motors, valves) through I/O modules (e.g., digital and analog outputs) using the computed results.

3. Communication and Data Interaction

- Built-in Communication Interfaces:

- Ethernet: Supports industrial protocols such as Modbus TCP, Profinet, and EtherNet/IP for connecting to host computers (SCADA/HMI), other controllers, or cloud platforms to enable data monitoring and remote control.

- Serial Interfaces (e.g., RS-485): Supports protocols like Modbus RTU and CANopen for connecting to field devices such as sensors and frequency converters.

- Data Exchange Mechanism:

Real-time data exchange with extended I/O modules via bus protocols (such as ABB's MasterBus 300) ensures synchronization of input and output signals. Supports Peer-to-Peer communication, allowing direct data exchange with other controllers without host computer intermediation.

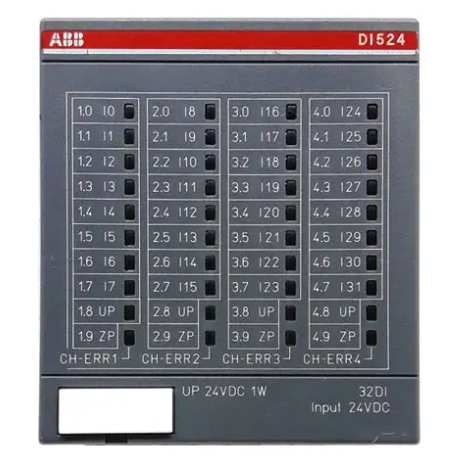

4. I/O Expansion and Signal Processing

- Modular Expansion:

The PP881 can connect to multiple I/O modules (e.g., Digital Input/Output DI/DO, Analog Input/Output AI/AO, high-speed counting modules, etc.), transmitting signals through bus interfaces (e.g., X20 terminals). - Signal Processing Logic:

- Converts input signals (e.g., 4-20mA current, 0-10V voltage from sensors) into digital quantities via Analog-to-Digital (A/D) conversion for CPU processing.

- Converts output signals (e.g., analog commands for frequency converters) into analog quantities via Digital-to-Analog (D/A) conversion to drive field devices.

- Supports interrupt handling: Prioritizes emergency signals (e.g., fault shutdown commands), interrupting the normal scan cycle to ensure system safety.

5. Reliability and Self-Diagnosis

- Industrial-Grade Design:

- Operating temperature range: -20°C ~ +60°C, supporting wide-temperature environments; protection rating IP20 (suitable for installation in control cabinets), resistant to vibration, impact, and electromagnetic interference (compliant with IEC 61000 standards).

- Redundancy mechanisms (some models): Support power and communication redundancy to ensure system operation under single-point failures.

- Self-Diagnosis Functions:

- Monitors internal component status in real time (e.g., processor load, memory errors, communication link quality), displaying operating status via LED indicators (e.g., RUN, FAULT, COMM).

- Supports online programming and debugging: Real-time variable monitoring, program modification, and download via Control Builder M software without downtime.

- Fault response: Triggers alarms and records fault logs when anomalies (e.g., I/O module communication interruptions) are detected, and can send alerts to SCADA systems via Ethernet.

6. Power and Energy Management

- Power Supply:

Supports DC (24V) or AC (85-264V) input, with built-in power filtering and voltage stabilization circuits, featuring surge and overvoltage protection to ensure stable operation under industrial power grid fluctuations. - Low-Power Design:

Typical power consumption <10W, supporting energy-saving modes to reduce heat dissipation requirements and extend hardware lifespan.