Description

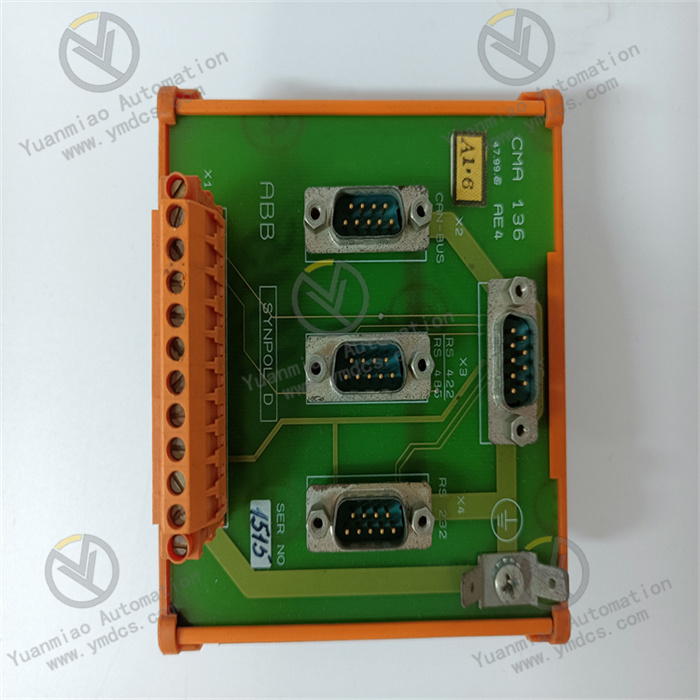

ABB CI810B 3BSE020520R1

ABB CI810B 3BSE020520R1 is a communication interface module belonging to the AC 800M controller series. It is primarily used to connect to PROFINET industrial Ethernet networks, enabling data interaction between controllers and field devices (such as sensors, actuators, and third-party controllers). It supports real-time communication, process monitoring, and automated control in distributed control systems (DCS).

Key Features

- Deep PROFINET Protocol Compatibility

- Supports PROFINET IO Controller and Device modes, capable of acting as a master station to connect distributed I/O devices or as a slave station to access higher-level control systems.

- Complies with PROFINET V2.3 standards, is compatible with the IEC 61158 industrial Ethernet protocol, and supports seamless integration with PROFINET devices from brands such as Siemens and Rockwell.

- High-Performance Communication Capability

- Communication Rate: 10/100 Mbps auto-adaptive, supporting full-duplex communication to ensure real-time data transmission (e.g., process variables, diagnostic information).

- Data Throughput: Supports large-capacity input/output data (e.g., 1440 bytes input/1440 bytes output), meeting the needs of high-speed control scenarios.

- Redundancy Mechanism: Supports PROFINET Media Redundancy (MRP) and controller redundancy configurations to enhance system reliability.

- Flexible System Integration

- Plug-and-Play: Directly inserts into the AC 800M controller backplane bus, automatically recognized by ABB Control Builder M software without additional drivers.

- Distributed Expansion: Can connect to ABB PM800/PM500 series distributed I/O modules or third-party PROFINET slave devices (such as remote I/O boxes and smart instruments).

- Industrial-Grade Reliability

- Environmental Adaptability: Operating temperature range of -20°C to +60°C, resistant to vibration and electromagnetic interference (compliant with EN 61000 standards), suitable for harsh industrial environments.

- Protection Level: IP20 (suitable for installation in control cabinets), meeting protection requirements for indoor industrial scenarios.

- Convenient Diagnosis and Maintenance

- LED Status Indicators: Real-time display of power (PWR), operation (RUN), communication (NET), fault (ERROR), and other statuses to quickly locate anomalies.

- Online Hot-Swap: Supports module replacement under power (requires power-off in non-redundant system modes or redundant configuration), reducing downtime.

Technical Specifications

| Parameter | Details |

|---|---|

| Communication Protocol | PROFINET IO (Controller/Device mode), compliant with IEC 61158-2 standards |

| Interface Type | 2 × RJ45 interfaces (support PROFINET bus connection with Auto-MDI/MDIX) |

| Maximum Number of Slaves | Supports up to 128 PROFINET slave devices when acting as a controller |

| Data Transmission Mode | Ethernet TCP/IP, UDP, IRT (isochronous real-time communication) |

| Power Requirement | Powered by AC 800M backplane (24V DC, power consumption approx. 300 mA) |

| Configuration Software | ABB Control Builder M, Engineering Toolbox (ET) |

| Mechanical Dimensions | Conforms to AC 800M module standard dimensions (approx. 100 mm × 160 mm × 40 mm, subject to manual) |

Application Scenarios

- Process Automation

- Chemical/Oil & Gas: Connects field transmitters (e.g., temperature, pressure sensors), control valves, etc., to achieve real-time monitoring and control of production processes.

- Pharmaceuticals/Food & Beverage: Integrates distributed I/O modules to meet high-precision control and compliance requirements (e.g., FDA, GMP) in cleanroom environments.

- Manufacturing Production Lines

- Automotive Manufacturing/Electronic Assembly: Connects to PROFINET devices such as robots, vision inspection systems, and frequency converters to achieve collaborative control and data traceability on production lines.

- Packaging Machinery: Connects to servo motors and sensor networks to support high-speed, high-precision packaging process automation.

- Power and Energy Management

- Smart Grid: Accesses relay protection devices and smart meters to enable data acquisition and remote control in substation SCADA systems.

- Renewable Energy: Connects to inverters and converters in wind and photovoltaic power plants to optimize energy management and scheduling.

- Building Automation

- HVAC Systems in Large Buildings: Connects to air handling units, elevator controllers, and energy meters to achieve centralized monitoring and energy efficiency optimization via PROFINET.

Operation and Maintenance Guide

1. Installation Steps

Hardware Installation:

- Vertically insert the module into the backplane slot of the AC 800M controller, ensuring the latch is securely locked.

- Connect PROFINET devices via CAT5e/CAT6 network cables. Shielded cables are recommended to reduce electromagnetic interference.

Software Configuration:

- Add the CI810B module in Control Builder M and configure PROFINET network parameters (e.g., device name, IP address, subnet mask).

- Import GSDML files of third-party slave devices, map input/output data to controller variables, and complete the communication configuration.

2. Status Monitoring

LED Indicator Meanings:

- PWR (Green): Steady on indicates normal power supply; off indicates a power failure.

- RUN (Green): Flashing indicates normal module operation; steady on or off indicates an abnormality.

- NET (Yellow): Flashing indicates PROFINET communication activity; steady on indicates a normal connection; off indicates no communication.

- ERROR (Red): Steady on indicates module faults or communication errors (e.g., slave disconnection, IP conflict), requiring software diagnostics for specific causes.

3. Common Fault Troubleshooting

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| NET indicator off | Disconnected network cable or IP conflict | Check network cable connections, reconfigure device IP, or restart network equipment |

| ERROR indicator on | Configuration errors or slave device faults | Re-import configuration files and check slave power supply and communication parameters |

| Large data transmission delay | High network load or improper real-time configuration | Optimize network topology and enable the IRT real-time communication mode |

| Module not recognized | Poor backplane contact or firmware incompatibility | Re-plug the module or upgrade the controller firmware |

Typical Networking Schematic

plaintext

AC 800M controller (with CI810B) ├─ PROFINET bus (100 Mbps) │ ├─ Distributed I/O modules (e.g., ABB PM861) │ ├─ Third-party PROFINET devices (e.g., Siemens ET200SP) │ └─ Smart sensors/actuators (e.g., flow meters, frequency converters with PROFINET interfaces) └─ Supervision and control system (e.g., ABB Industrial IT)