Description

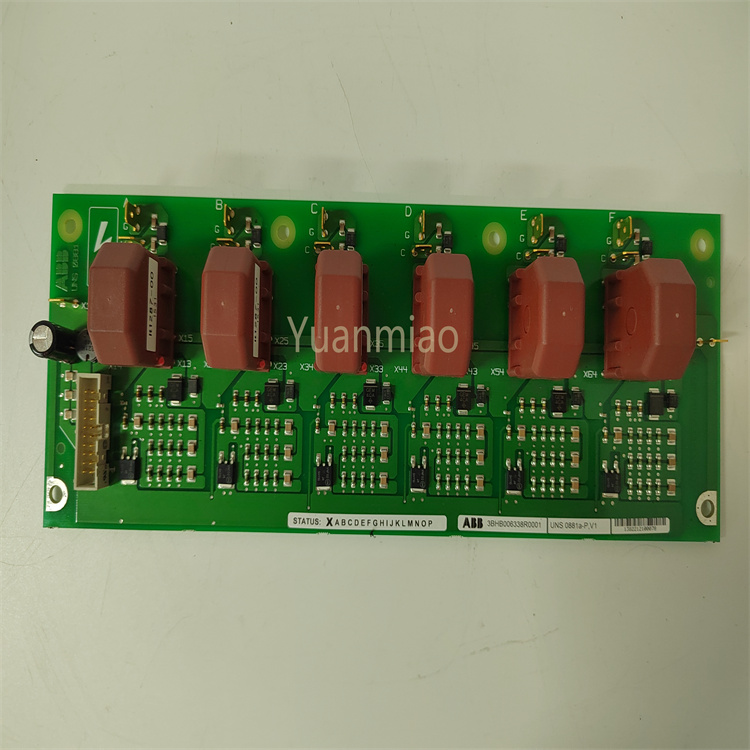

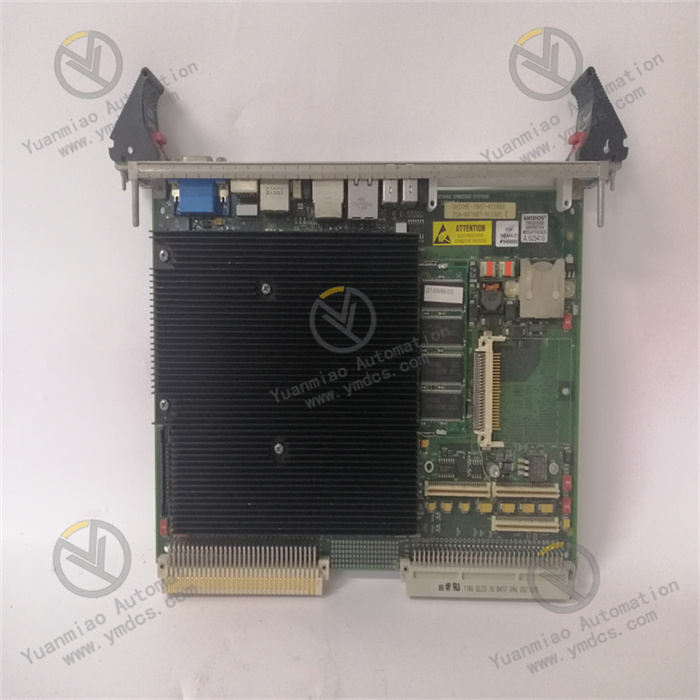

ABB AI895 3BSC690086R1

ABB AI895 3BSC690086R1 is an analog input module dedicated to receiving analog signals output by various industrial sensors such as those for temperature, pressure, flow rate and liquid level. Through its internal precision signal conditioning, isolation and A/D conversion circuits, it converts analog signals into digital signals recognizable by controllers, providing accurate data support for process control, data monitoring, fault early warning and other scenarios. Equipped with multi-channel acquisition capability, native HART protocol support and comprehensive diagnostic functions, it adopts an industrial-grade enhanced design and is widely used in fields with stringent requirements for signal acquisition accuracy and stability, including petrochemicals, power energy, metallurgical manufacturing and municipal infrastructure. It can be seamlessly integrated with ABB series controllers and dedicated terminal units to ensure the efficient and stable operation of automated systems.

I. Product Features

1. Multi-channel High-precision Acquisition with Comprehensive Signal Compatibility

2. Native HART Protocol Support with Strong Intelligent Interaction Capability

3. Full Isolation Protection Design with Excellent Anti-interference Performance

4. Comprehensive Onboard Diagnostics for Efficient Operation and Maintenance

5. Modular Architecture with Excellent Compatibility and Scalability

6. Enhanced Environmental Adaptability for Stable and Reliable Operation

II. Technical Specifications

1. Basic Parameters

- Model: ABB AI895 3BSC690086R1

- Product Type: Analog Input Module

- Product Series: ABB S800 I/O Series

- Brand: ABB

- Application Fields: Petrochemicals, Power Energy, Metallurgical Manufacturing, Municipal Infrastructure, Intelligent Manufacturing

- Compatible Systems: Industrial automation systems such as ABB 800xA Distributed Control System

- Compatible Terminal Units: S800 I/O series terminal units such as TU 810, TU 812, TU 814, TU 818, TU 830

- Mounting Method: DIN Rail Mounting (Compliant with EN 50022 Standard)

- Net Weight: Approximately 0.38kg

- Warranty Period: 12 Months

- RoHS Compliance: Conforms to EU Directive 2011/65/EU (RoHS 2.0)

- WEEE Category: Category 5 (Small Electronic Equipment)

2. Electrical Parameters

- Number of Input Channels: 8 Channels (Differential Input)

- Input Signal Types: Current signals (4-20mA, 0-20mA), Voltage signals (0-10V, 1-5V), Thermocouples (Type J, K, S, T, R, B, E, N), Thermal resistors (Pt100, Pt1000, Cu50, Cu100)

- Resolution: 16-bit

- Measurement Accuracy: ±0.05% FS (Current/Voltage signals), ±0.1℃ (Temperature signals, Pt100, -100℃~600℃)

- Isolation Class: Full isolation between input channels, input-output and input-power supply, rated isolation voltage 250V AC (Continuous)

- Transmitter Power Supply: 24V DC, current limit ≤23mA per channel

- Communication Protocol: HART 7.0, compatible with industrial standard protocols such as Modbus

- Power Consumption: Typical value ≤6W (Full-load operating condition)

- Response Time: ≤10ms (Current/Voltage signals), ≤500ms (Temperature signals, Pt100)

3. Mechanical & Environmental Parameters

- Dimensions (W×H×D): 45mm×119mm×105mm

- Operating Temperature: -25℃~+70℃

- Storage Temperature: -40℃~+85℃

- Relative Humidity: 5%~95%RH (Non-condensing)

- Electromagnetic Immunity: Compliant with EN 55011 Group 1 Class A, EN 61000-4-2 (ESD), EN 61000-4-3 (Radiated Immunity), EN 61000-4-4 (Electrical Fast Transient), EN 61000-4-5 (Surge) standards

- Vibration Resistance: Compliant with IEC 60068-2-6 standard, 10-150Hz, acceleration 5g

- Shock Resistance: Compliant with IEC 60068-2-27 standard, acceleration 15g, duration 11ms

- Protection Class: IP20 (Front-end protection after DIN rail mounting)

III. Working Principle

The core working logic of the ABB AI895 3BSC690086R1 analog input module follows the sequence of "Signal Access - Power Supply Guarantee - Conditioning & Preprocessing - Conversion & Transmission - Status Monitoring - Diagnostic Feedback". The specific workflow is as follows:

- Signal Access and Power Supply Guarantee: Analog signals output by front-end industrial sensors (e.g., pressure sensors, thermocouples, thermal resistors, etc.) are connected to the module's 8 input channels via dedicated differential terminals. The module provides stable 24V DC power for sensors requiring power supply (e.g., 4-20mA two-wire sensors) through its built-in current-limited power supply circuit, while limiting the output current to avoid module damage caused by sensor short circuit or overload.

- Signal Conditioning and Preprocessing: The accessed analog signals first pass through the module's internal dedicated conditioning circuits and are processed specifically for different signal types—current signals are converted into voltage signals via precision resistors; temperature signals (thermocouples/thermal resistors) undergo cold-junction compensation and signal amplification. At the same time, electromagnetic interference from industrial sites (e.g., interference generated by frequency converters and high-voltage cables) is removed through filter circuits. Electrical isolation between input signals and backend circuits is then achieved through isolation circuits, further improving signal stability and system safety.

- A/D Conversion and Data Transmission: The preprocessed standard analog signals are sent to the 16-bit high-precision A/D conversion circuit and converted into digital signals. After being processed by the module's internal logic circuit, the digital signals are transmitted to controllers such as ABB 800xA via the S800 I/O system bus. If HART intelligent sensors are connected, the module realizes two-way transmission of measured data and sensor status information through the HART protocol parsing circuit, and the controller can issue remote configuration and calibration commands to the sensors via the module.

- Status Monitoring and Diagnostic Feedback: The module real-time monitors its own power supply voltage, A/D conversion circuit working status, input signal integrity of each channel (e.g., overrange, open circuit, short circuit) and HART communication link status. When an abnormality is detected, it immediately activates the onboard diagnostic mechanism, generates fault codes containing fault location and type, feeds them back to the control system via the communication link, and triggers corresponding local alarm indicators (power alarm, channel alarm, communication alarm) to remind maintenance personnel to handle the problem in a timely manner.

IV. Common Troubleshooting

| Fault Phenomenon | Possible Causes | Troubleshooting and Solutions |

|---|---|---|

| Power indicator not lit, module unresponsive | Abnormal power supply (power failure, voltage out of range), loose or reversed polarity of power terminal wiring, poor connection between module and terminal unit, internal power circuit failure of the module | Use a multimeter to measure the voltage at the module's power terminals to ensure it meets the 24V DC±10% requirement; check if the power terminal wiring is firm and verify the correctness of polarity connection; inspect the connection between the module and the terminal unit to ensure it is properly seated and firm, re-plug to confirm reliable connection; if the above checks are all normal but the module remains unresponsive, internal power circuit failure may be the cause—contact ABB authorized after-sales service for repair or replacement. |

| Large deviation in collected data, unstable signals | Loose or poor connection of input signal cables, incorrect differential wiring (reversed polarity), poor or ungrounded shielded cables, strong external electromagnetic interference, uncalibrated module or lost calibration parameters, sensor malfunction, ambient temperature beyond the module's adaptive range | Re-tighten the input signal terminal wiring and verify the correctness of differential signal polarity connection; check whether shielded cables are used for signal cables and ensure the shielding layer is grounded at one end (grounding at the controller end is recommended), keep away from strong interference sources such as frequency converters and high-voltage cables; if strong interference exists, install a metal shield or replace with twisted-pair shielded cables; calibrate the module's precision with a standard signal source and restore calibration parameters; connect the sensor to other normal channels for testing to determine if it is faulty, replace it if necessary; check the module's operating ambient temperature and take cooling or heat preservation measures if it exceeds the -25℃~+70℃ range. |

| HART communication failure, unable to read/write sensor parameters | Incorrect or broken communication cable connections, mismatched HART communication parameters (e.g., address, baud rate), sensors that do not support HART protocol or have not enabled HART function, module HART parsing circuit failure, incorrect communication configuration of terminal unit | Check if the HART communication cable wiring is correct and firm, and whether there is any disconnection or poor connection; re-verify the wire sequence according to HART protocol requirements; confirm that the HART communication parameters (address, baud rate) of the module and sensor are consistent, reconfigure via the control system if mismatched; verify whether the sensor supports HART protocol and whether the HART function is enabled, enable it according to the sensor manual if not; replace the communication cable or test the module's communication interface to rule out interface faults; check the communication configuration of the terminal unit to ensure it matches the module and controller. |

| No data collected from specific channels, channel alarm indicator lit | Loose or broken wiring of the channel, sensor malfunction or no power supply, reversed polarity of the channel, internal damage to the module channel | Re-tighten the signal wiring of the channel and check for cable breaks; inspect whether the corresponding sensor of the channel is powered normally, connect the sensor to other normal channels for testing to determine if it is faulty, repair or replace it if necessary; verify the correctness of the channel signal polarity connection, re-wire if reversed; if the above checks are all normal, internal damage to the module channel may be the cause—contact ABB authorized after-sales service for repair. |

| Module frequently triggers overall alarm, multi-channel data abnormal | Excessive fluctuation of module power supply voltage, poor connection between module and terminal unit, strong external electromagnetic interference, overall loss of module calibration parameters, internal logic circuit failure of the module | Measure the module's power supply voltage, install a voltage stabilizer at the front end if the fluctuation is excessive; check the connection between the module and the terminal unit, re-plug and fasten it; strengthen electromagnetic interference protection, check the grounding of shielded cables and cable layout, keep away from strong interference sources; perform overall precision calibration on the module and restore calibration parameters; if the alarm is still frequent after calibration, internal logic circuit failure of the module may be the cause—contact after-sales service for repair or replacement. |

| Abnormal temperature signal collection (e.g., large display deviation, no display) | Thermocouple cold-junction compensation failure, incorrect thermal resistor wiring (e.g., three-wire system connected as two-wire system), temperature sensor damage, module temperature signal conditioning circuit failure | For thermocouple signals, check if the module's cold-junction compensation function is normal, which can be verified with a standard temperature source; for thermal resistor signals, verify the correctness of the wiring method (three-wire/four-wire system) and ensure cable resistance matching; connect the temperature sensor to other normal channels for testing to determine if it is damaged, replace it if necessary; if both the sensor and wiring are normal, module temperature signal conditioning circuit failure may be the cause—contact after-sales service for repair. |