Description

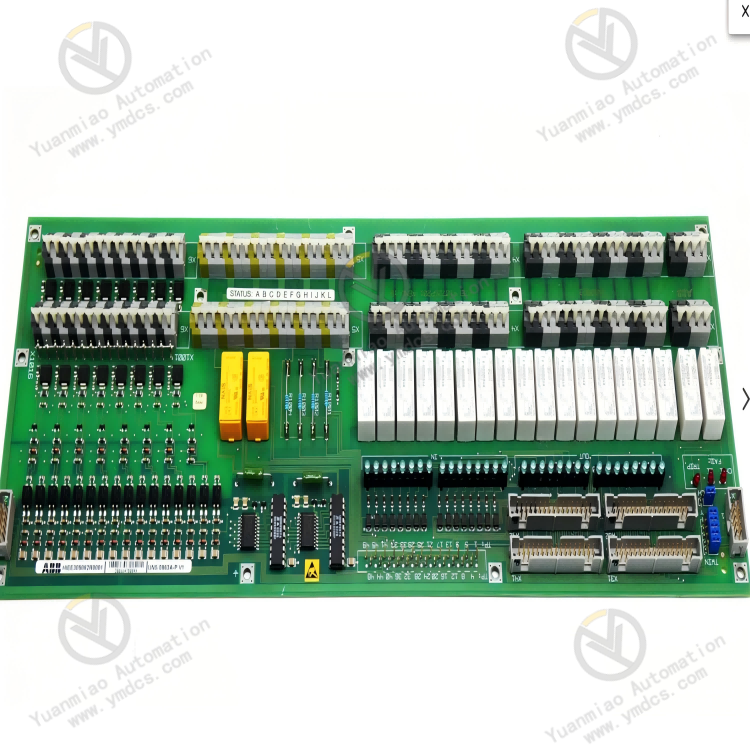

ABB PFSK160A 3BSE009514R1

I. Overview

ABB PFSK160A 3BSE009514R1 is a digital output relay module, positioned as a "digital signal conversion and execution control unit for industrial control systems". The core function of this module is to convert digital signals output by upper-level devices such as PLCs and DCSs into relay or transistor output signals, achieving precise control of actuators like motors, valves, heaters and indicator lights. Meanwhile, it integrates signal conditioning and isolation protection functions, enabling stable transmission of control commands in complex industrial environments and ensuring the reliable operation of automation systems.

II. Core Features

Multiple Output Configurations & Flexible Adaptability: Supports three selectable output modes: relay output, transistor output and hybrid output. Each output channel has a maximum carrying current of 10A and a maximum switching frequency of 100Hz. The output mode can be flexibly selected according to the type of actuator (inductive/resistive load), adapting to different control requirements such as motor start-stop, valve switching and lighting control.

Industrial-grade Reliability & Environmental Resistance: Adopts high-quality electronic components and strict quality control processes, providing strong anti-interference and anti-vibration capabilities; the IP67 protection rating can effectively prevent the intrusion of dust and water. With an operating temperature range of -20℃ ~ 60℃, it can operate continuously and stably for 24 hours in harsh industrial environments with high and low temperatures, humidity and dust.

Easy Integration & Configuration Debugging: Adopts a standardized interface design, supporting seamless connection with PLC and DCS systems, and is compatible with mainstream communication protocols such as Profibus DP and HART, ensuring stable and efficient data transmission; supports user-defined programming and parameter configuration, allowing adjustment of output logic according to on-site requirements, with convenient installation and debugging, greatly reducing system integration costs.

Signal Conditioning & Safety Protection: Built-in signal isolation and conditioning circuits can effectively block the impact of external electromagnetic interference on control signals, avoiding control failure caused by signal distortion; it also has overload protection and short-circuit protection functions. When the load of the output channel is abnormal, it can quickly cut off the circuit to protect the safety of the module and downstream actuators.

- Compact Design & Convenient Operation and Maintenance: Adopts a lightweight and compact structure, with a small size and a net weight of only about 60g, enabling dense installation in equipment cabinets and saving space; the modular design facilitates separate disassembly and replacement without overall shutdown. Combined with clear status indicator lights, it allows quick troubleshooting, reducing operation and maintenance difficulty and downtime losses.

III. Technical Parameters

| Parameter Name | Specification |

|---|---|

| Product Model | ABB PFSK160A 3BSE009514R1 |

| Product Type | Digital output relay module, dedicated for industrial automation control |

| Product Attributes | Modular design, IP67 protection, signal isolation |

| Power Supply Parameters | Operating Voltage: DC 24V; Rated Current: 108mA |

| Output Parameters | Output Type: Relay/Transistor/Hybrid output optional; Maximum Single-channel Current: 10A; Switching Frequency: Up to 100Hz |

| Communication Method | Supports Profibus DP and HART protocols; Standardized interface, compatible with PLC/DCS systems |

| Physical Parameters | Dimensions: 73.5mm×25.5mm×11mm; Net Weight: Approx. 60g; Mounting Method: Embedded/DIN rail mounting |

| Environmental Adaptability | Operating Temperature: -20℃~60℃; Protection Rating: IP67; EMC Resistance (IEC 61000-4) |

| Compatibility & Adaptation | Compatible with various PLC and DCS control systems; Suitable for actuators such as motors, valves and heaters |

| Additional Information | Warranty Period: 12 months; Protection Functions: Overload protection, short-circuit protection, signal isolation protection |

IV. Working Principle and Application Logic

The ABB PFSK160A 3BSE009514R1 module realizes signal conversion and execution control in industrial control systems based on the core working logic of "digital signal reception - signal conditioning - output conversion - status feedback". Its core working process is as follows:

The module receives digital control signals sent by upper-level devices such as PLCs and DCSs through communication interfaces, and completes power supply initialization and self-diagnosis at the same time, confirming that the internal circuits and output channels of the module are in normal working condition, and forming a ready signal to feed back to the upper-level device.

The built-in signal conditioning circuit filters and amplifies the received digital signals to eliminate signal noise caused by external electromagnetic interference; at the same time, the isolation circuit blocks electrical loop interference between upper and lower devices, ensuring the stability and accuracy of signal transmission.

According to the preset output mode (relay/transistor/hybrid), the conditioned digital signals are converted into corresponding types of output signals to drive downstream actuators (motors, valves, etc.) to complete actions such as start-stop and switching; meanwhile, it monitors the current and load status of the output channels in real time to ensure the normal operation of the actuators.