Description

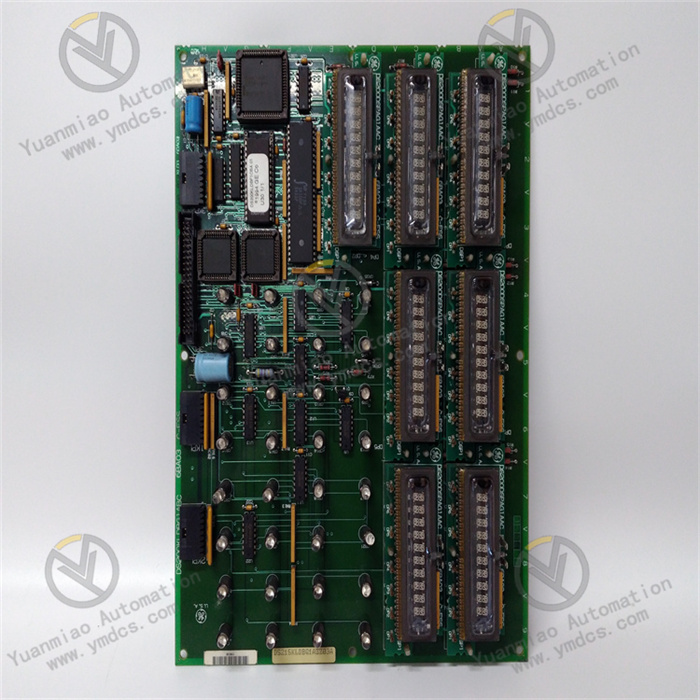

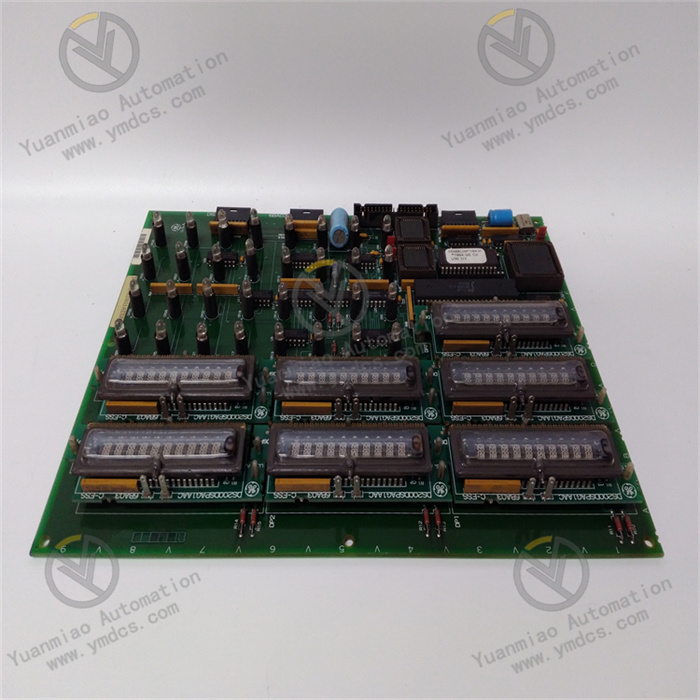

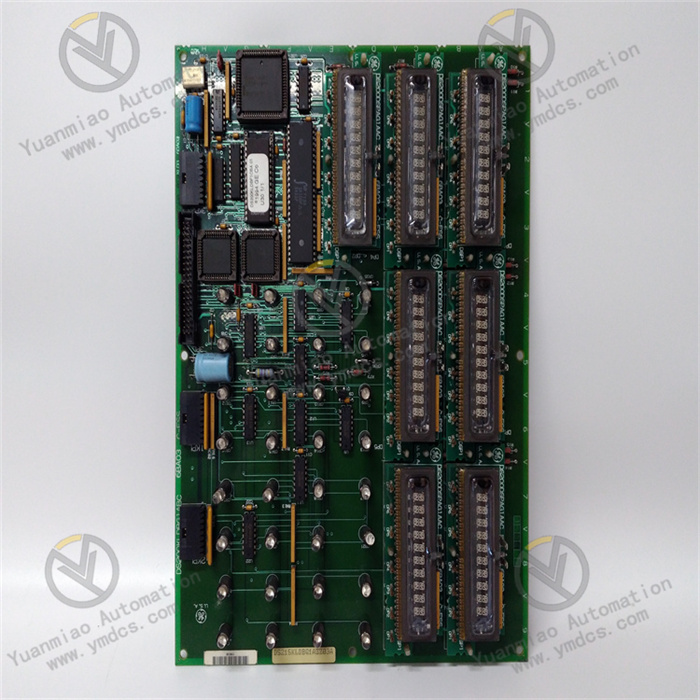

DS215KLDCG1AZZ03A

I. Overview

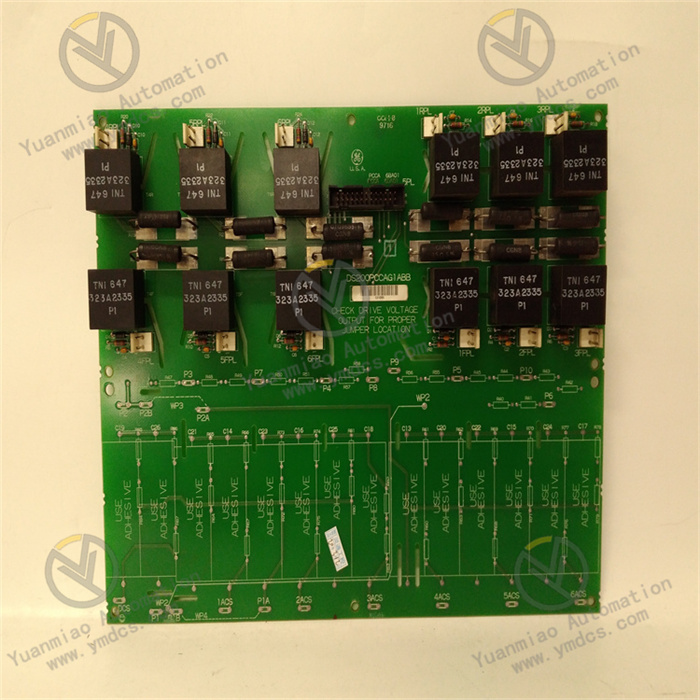

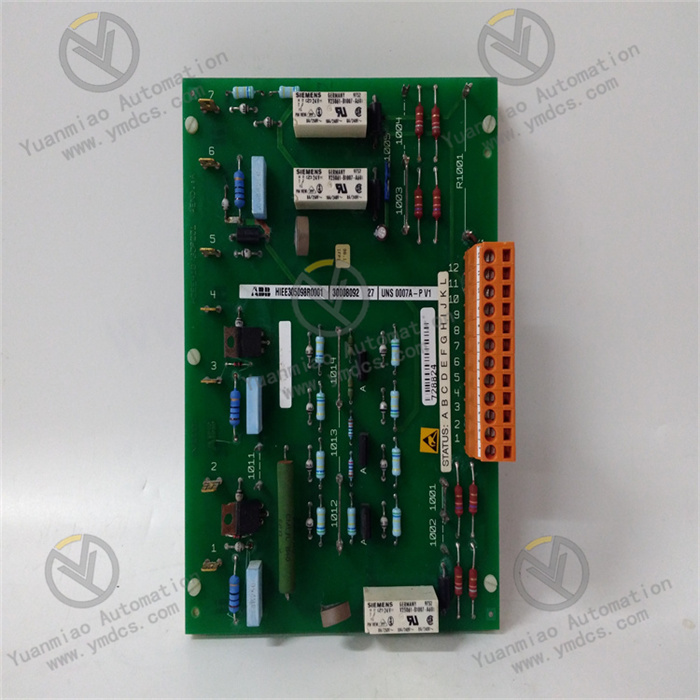

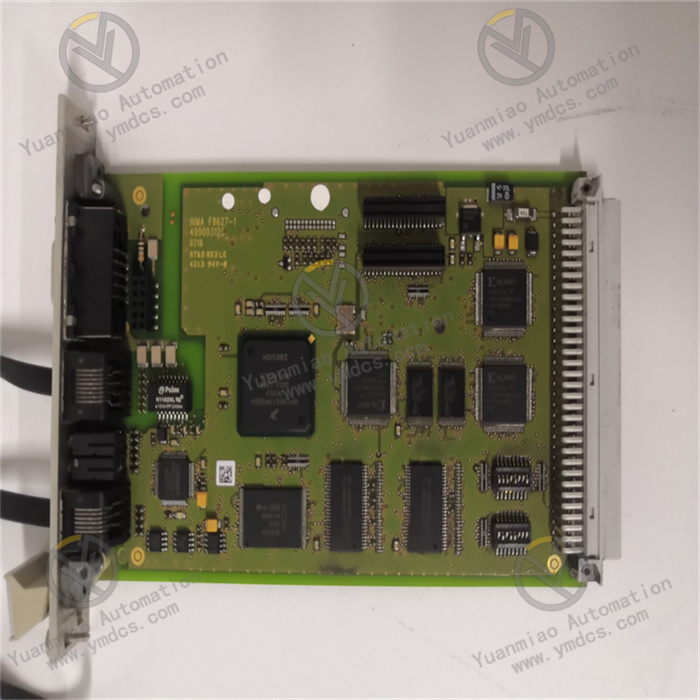

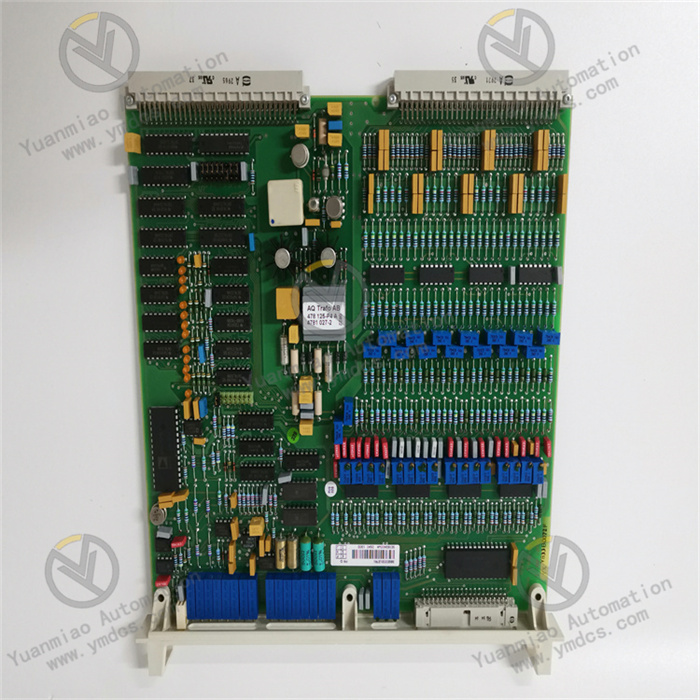

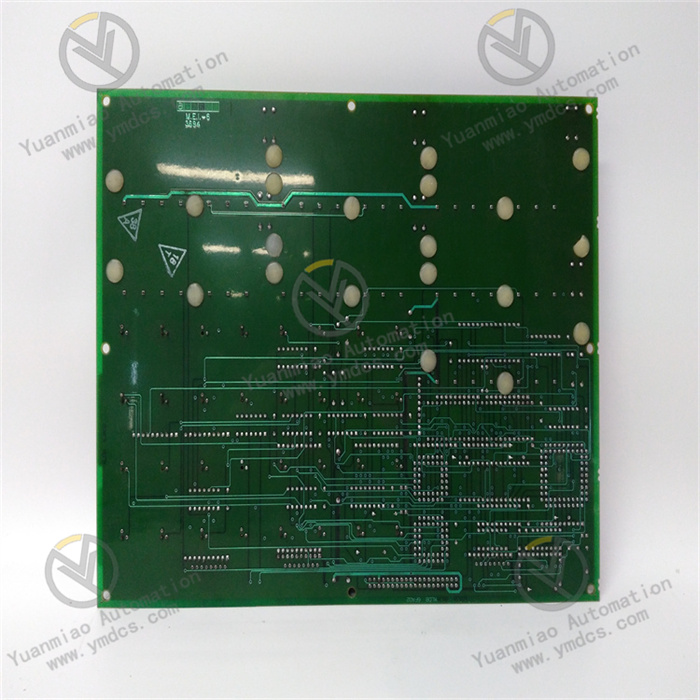

GE DS215KLDCG1AZZ03A is a widely used equipment component, playing a crucial role in various industrial scenarios. It can be found in the automation control systems and instruments of industries such as electricity, petroleum, chemical engineering, pharmaceuticals, food processing, and water treatment. In the turbine control systems of power plants and substations within the power system, it serves as a key part to ensure the stable operation of the systems. In the food processing industry, its stable and reliable performance guarantees the precision of automated production line control. It can be the core printed circuit board in the GE Speedtronic Mark V turbine control system, carrying complex electronic circuits to perform key tasks such as signal processing and data transmission. It can also function as an isolated terminal board for contact input groups, enabling dry contact input connections and signal noise reduction processing.

II. Functional Features

High Reliability: Designed to meet industrial-grade standards, it can adapt to harsh industrial environments, such as high temperatures, high humidity, and strong electromagnetic interference. This ensures the long-term stable operation of the equipment and reduces the failure rate caused by environmental factors.

Customized Adaptation: For example, the version specifically tailored for the Mark V system can perfectly match other components within the system, fully leveraging the performance advantages of the entire system and ensuring the smooth and efficient collaborative operation of all parts.

High-Density Integration: It highly integrates various electronic components within a limited space. While reducing the product volume, it realizes a rich and powerful set of functions, minimizing the overall footprint of the equipment and facilitating the compact design and installation of the system.

Modular Design: The modular structure makes the installation process simple and convenient. During equipment maintenance, if a certain module malfunctions, it can be directly repaired or replaced, greatly reducing the maintenance difficulty and cost and improving the maintainability of the equipment.

Stable Signal Processing and Transmission: Equipped with precise signal transmission circuits, it can ensure stable and accurate transmission of signals, whether processing various signals from devices such as sensors and actuators or conducting data transmission within the control system to enable communication between different modules, reducing signal distortion and interference.

Noise Reduction and Surge Protection: When used as an isolated terminal board for contact input groups, the noise reduction circuit in the contact input can effectively protect the equipment from surges and high-frequency noise, ensuring the purity and stability of the input signals and enhancing the system's adaptability to complex electromagnetic environments.

Customized Adaptation: For example, the version specifically tailored for the Mark V system can perfectly match other components within the system, fully leveraging the performance advantages of the entire system and ensuring the smooth and efficient collaborative operation of all parts.

High-Density Integration: It highly integrates various electronic components within a limited space. While reducing the product volume, it realizes a rich and powerful set of functions, minimizing the overall footprint of the equipment and facilitating the compact design and installation of the system.

Modular Design: The modular structure makes the installation process simple and convenient. During equipment maintenance, if a certain module malfunctions, it can be directly repaired or replaced, greatly reducing the maintenance difficulty and cost and improving the maintainability of the equipment.

Stable Signal Processing and Transmission: Equipped with precise signal transmission circuits, it can ensure stable and accurate transmission of signals, whether processing various signals from devices such as sensors and actuators or conducting data transmission within the control system to enable communication between different modules, reducing signal distortion and interference.

Noise Reduction and Surge Protection: When used as an isolated terminal board for contact input groups, the noise reduction circuit in the contact input can effectively protect the equipment from surges and high-frequency noise, ensuring the purity and stability of the input signals and enhancing the system's adaptability to complex electromagnetic environments.

III. Technical Parameters

| Technical Parameter | Details |

|---|---|

| Operating Voltage | 24V (in some application scenarios), and some materials mention that the maximum voltage can reach 220V |

| Current | 100 - 400A |

| Output Frequency | 50HZ |

| Frequency Range | 50 - 60Hz |

| Operating Temperature | -20℃ ~ +45℃ |

| Protection Level | IP65 (some materials show that related products can reach IP67) |

| Data Transmission Medium | Ethernet / EtherCAT cable (minimum Cat. 5), shielded type |

| Protocol | EtherCAT |

| Data Transmission Rate | 100 Mbit/s |

IV. Working Principle

As a Printed Circuit Board: In electronic devices, it serves as the foundation for supporting, connecting, and fixing electronic components. Through the electrical circuits printed on the board, it realizes the electrical connection between electronic components, thus constructing a complete electronic circuit. These circuits process various input electrical signals according to the designed logic. For example, they perform operations such as analog-to-digital conversion, amplification, and filtering on the analog signals transmitted by sensors, and then transmit the processed signals to other relevant modules to achieve various predetermined functions of the device.

As an Isolated Terminal Board for Contact Input Groups: Twenty-four dry contact inputs are connected to two barrier terminal blocks on the contact input (TBCI) terminal board with group isolation. TBCI is coupled with a DC power supply for contact excitation, and the noise reduction circuit in the contact input starts to work, performing noise reduction and surge protection processing on the input signals. In simplex and TMR applications, TBCI is connected to the I/O processor through specific connectors (for example, connector JR1 is used in the simplex system; connectors JR1, JS1, and JT1 are used in the TMR system), realizing the connection with the VME rack, and then transmitting the processed signals to the control system, so that the system can make corresponding control decisions based on these input signals.

As an Isolated Terminal Board for Contact Input Groups: Twenty-four dry contact inputs are connected to two barrier terminal blocks on the contact input (TBCI) terminal board with group isolation. TBCI is coupled with a DC power supply for contact excitation, and the noise reduction circuit in the contact input starts to work, performing noise reduction and surge protection processing on the input signals. In simplex and TMR applications, TBCI is connected to the I/O processor through specific connectors (for example, connector JR1 is used in the simplex system; connectors JR1, JS1, and JT1 are used in the TMR system), realizing the connection with the VME rack, and then transmitting the processed signals to the control system, so that the system can make corresponding control decisions based on these input signals.

V. Common Faults and Solutions

Abnormal Signal Transmission

Fault Phenomenon: Devices cannot communicate normally, with signal loss or incorrect data transmission.

Possible Causes: Loose network connection, cable damage, malfunction of the signal transmission circuit on the circuit board.

Solutions: Check whether the Ethernet / EtherCAT cable connection is secure. If loose, re-plug it. Use professional tools to detect whether the cable is damaged and replace it if necessary. If it is suspected that there is a problem with the signal transmission circuit of the circuit board, professional technicians are required to detect and repair the circuit board, and replace the damaged circuit components if necessary.

Power Failure

Fault Phenomenon: The device cannot start, and the indicator light does not turn on.

Possible Causes: Interruption of power supply, unstable voltage, malfunction of the power module on the circuit board.

Solutions: Check the external power connection to confirm whether the power socket is supplying power normally. Use a multimeter to measure whether the input voltage is within the specified operating voltage range of the device. If the voltage is unstable, investigate the problems of the power supply line or install a voltage regulator. For the malfunction of the power module on the circuit board, professional personnel are required to detect and repair it, and replace the damaged power module components.

Contact Input Failure

Fault Phenomenon: The dry contact input signals cannot be correctly recognized by the system, resulting in misjudgment or no response.

Possible Causes: Contact oxidation, poor contact, malfunction of the noise reduction circuit.

Solutions: For contact oxidation or poor contact problems, use professional cleaning agents to clean the contacts and check whether the connection terminals are tightened. If it is suspected that there is a problem with the noise reduction circuit, detect the noise reduction circuit and repair or replace the damaged noise reduction circuit components.

Module Communication Failure (such as involving EtherCAT communication)

Fault Phenomenon: In the EtherCAT system, communication between this module and other terminal modules is interrupted, causing some functions of the system to fail.

Possible Causes: Incorrect configuration of the EtherCAT protocol, damage to the EtherCAT interface of the module, incorrect network topology.

Solutions: Carefully check the relevant configuration parameters of the EtherCAT protocol to ensure they are consistent with the system requirements. Use professional equipment to detect whether the EtherCAT interface of the module is working properly. If the interface is damaged, repair or replace the module. Recheck the network topology structure to ensure it complies with the wiring rules and requirements of the EtherCAT network and eliminate communication problems caused by incorrect topology.

Fault Phenomenon: Devices cannot communicate normally, with signal loss or incorrect data transmission.

Possible Causes: Loose network connection, cable damage, malfunction of the signal transmission circuit on the circuit board.

Solutions: Check whether the Ethernet / EtherCAT cable connection is secure. If loose, re-plug it. Use professional tools to detect whether the cable is damaged and replace it if necessary. If it is suspected that there is a problem with the signal transmission circuit of the circuit board, professional technicians are required to detect and repair the circuit board, and replace the damaged circuit components if necessary.

Power Failure

Fault Phenomenon: The device cannot start, and the indicator light does not turn on.

Possible Causes: Interruption of power supply, unstable voltage, malfunction of the power module on the circuit board.

Solutions: Check the external power connection to confirm whether the power socket is supplying power normally. Use a multimeter to measure whether the input voltage is within the specified operating voltage range of the device. If the voltage is unstable, investigate the problems of the power supply line or install a voltage regulator. For the malfunction of the power module on the circuit board, professional personnel are required to detect and repair it, and replace the damaged power module components.

Contact Input Failure

Fault Phenomenon: The dry contact input signals cannot be correctly recognized by the system, resulting in misjudgment or no response.

Possible Causes: Contact oxidation, poor contact, malfunction of the noise reduction circuit.

Solutions: For contact oxidation or poor contact problems, use professional cleaning agents to clean the contacts and check whether the connection terminals are tightened. If it is suspected that there is a problem with the noise reduction circuit, detect the noise reduction circuit and repair or replace the damaged noise reduction circuit components.

Module Communication Failure (such as involving EtherCAT communication)

Fault Phenomenon: In the EtherCAT system, communication between this module and other terminal modules is interrupted, causing some functions of the system to fail.

Possible Causes: Incorrect configuration of the EtherCAT protocol, damage to the EtherCAT interface of the module, incorrect network topology.

Solutions: Carefully check the relevant configuration parameters of the EtherCAT protocol to ensure they are consistent with the system requirements. Use professional equipment to detect whether the EtherCAT interface of the module is working properly. If the interface is damaged, repair or replace the module. Recheck the network topology structure to ensure it complies with the wiring rules and requirements of the EtherCAT network and eliminate communication problems caused by incorrect topology.