Description

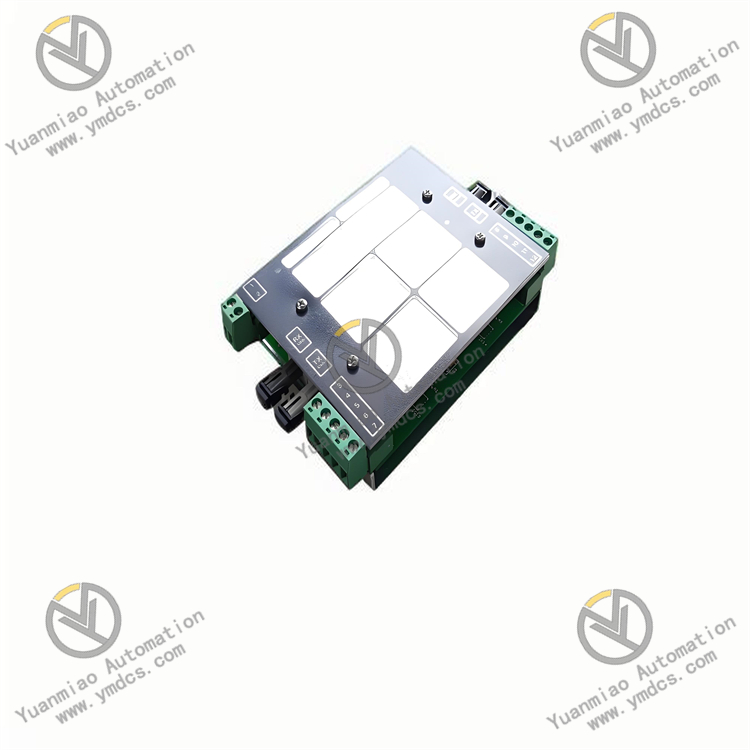

Praxis 98.6.040.701

I. Overview

II. Technical Parameters

Data transmission rate: The maximum data transmission rate can reach 12Mbps, which can quickly transmit a large amount of industrial data, ensuring the timely delivery of equipment control commands and real-time status information, and meeting the high efficiency requirements of industrial automation systems for data processing.

Electrical characteristics: The working voltage is 24V DC, and it can operate stably within a power supply fluctuation range of ±10%, adapting to common power supply fluctuations in industrial sites. The device has low power consumption, with a typical value of 3W, reducing energy consumption and operating costs.

Isolation performance: It has a strong electrical isolation function. The isolation voltage between input, output and power supply is as high as 2500V AC, which effectively prevents electrical interference between different circuits, ensures the stable operation of the device in complex electromagnetic environments, and avoids data transmission errors or equipment failures caused by interference.

Environmental adaptability: The operating temperature range is -40°C to +85°C, and it can operate normally in extremely low or high temperature environments, such as cold cold storage workshops or hot steel smelting workshops. The relative humidity is 5%-95% (no condensation), adapting to humid environments. The protection level reaches IP30, which can effectively prevent dust and small foreign objects from entering, ensuring reliability in harsh industrial environments.

Dimensions and installation method: The product has a compact size of 120mm×80mm×50mm (length × width × height), saving space in the control cabinet. It adopts a standard DIN rail installation method, which is convenient and fast, and can be easily integrated into existing industrial automation systems, reducing installation costs and time.

III. Functional Advantages

Multi-protocol compatibility: It supports multiple fieldbus protocols, and can flexibly adapt to industrial equipment of different brands and types. Whether it is the transformation of old equipment or the construction of new systems, it can easily realize interconnection and intercommunication between devices without complex protocol conversion equipment, reducing the difficulty and cost of system integration.

Efficient data conversion: Equipped with a high-performance processor, it can quickly and accurately convert fieldbus signals and fiber optic signals, ensuring efficient data transmission between different communication media, meeting the strict real-time requirements of industrial automation systems, enabling the control system to timely respond to changes in equipment status and make accurate control decisions.

Stable industrial-grade design: From electrical performance to environmental adaptability, it is designed and manufactured in accordance with industrial-grade standards, with high reliability and durability. After strict EMC (Electromagnetic Compatibility) testing, it can operate stably in strong electromagnetic interference environments, reducing the frequency of equipment maintenance and improving the overall operating efficiency of the production system.

Status monitoring and diagnosis: The device has a complete status monitoring function. Through LED indicators, it can intuitively display communication status, power status, data transmission status, etc., facilitating operators to quickly judge whether the equipment is running normally. Once a fault occurs, the built-in diagnosis function can quickly locate the problem, shorten the fault troubleshooting time, and improve the availability of the production system.

IV. Application Scenarios

Intelligent warehousing and logistics systems: In large-scale warehousing and logistics centers, it is used to connect the fieldbus of logistics equipment such as stackers, conveyors, and shuttle cars with fiber optic networks, ensuring real-time and accurate exchange of information such as cargo positions and operating status between devices, enabling the entire warehousing and logistics system to operate efficiently and coordinately, and realizing rapid storage, sorting and distribution of goods.

Energy and power industry: In places such as substations and power plants, it converts the fieldbus signals of on-site equipment such as smart meters, relay protection devices, and measurement and control units into fiber optic signals, which are transmitted to the monitoring center over long distances, ensuring reliable transmission of power system data, realizing remote monitoring and control of power equipment, and improving the safety and stability of power system operation.

Mining and processing: In the harsh environment of mines, it connects the fieldbus of mining equipment (such as crushers, hoists, ventilators) with fiber optic networks, overcomes adverse factors such as dust, humidity, and electromagnetic interference, realizes stable transmission of equipment operation data, provides reliable communication support for automated mining and processing of mines, and improves the safety and efficiency of mine production.