Description

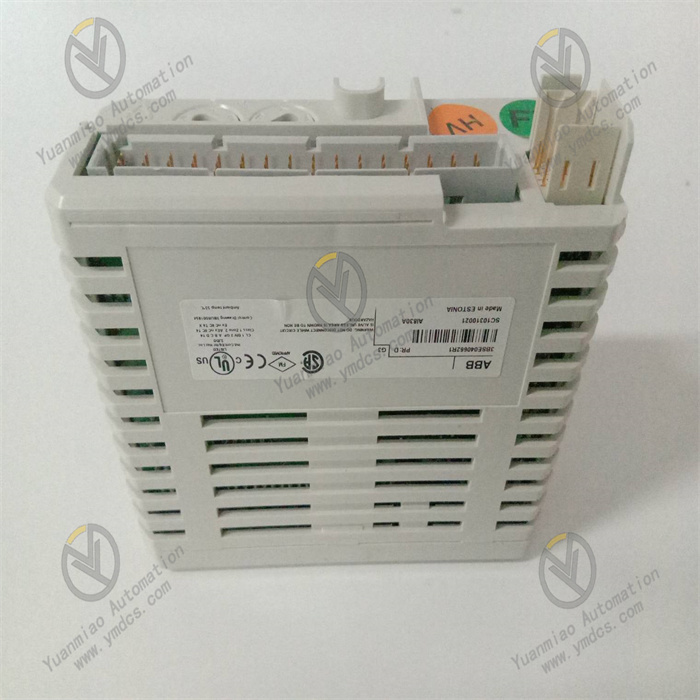

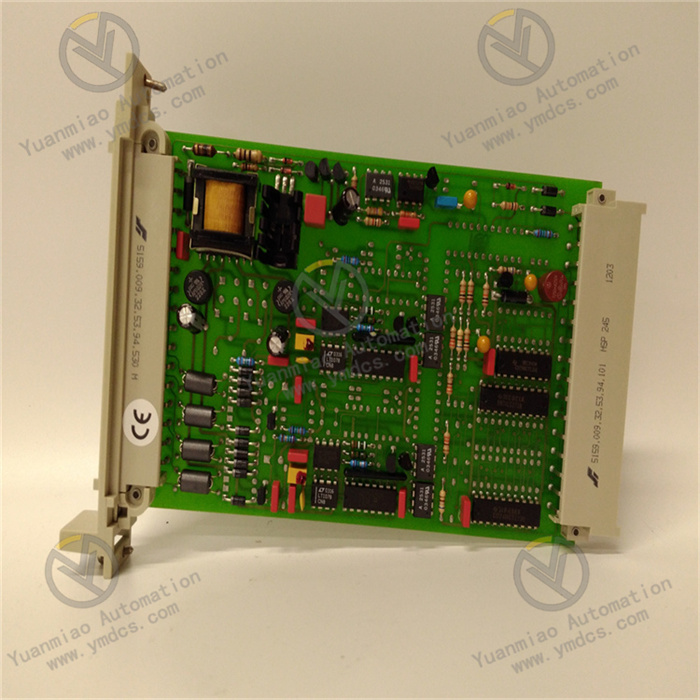

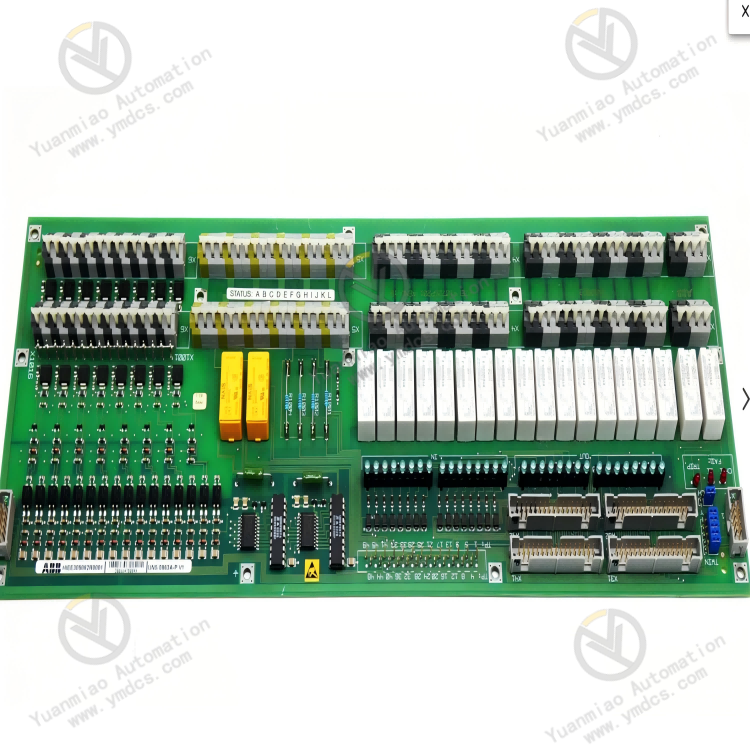

Functional Features Generally, products of this kind may have high-precision measurement or control functions, and are capable of precisely sensing and adjusting specific physical quantities or process parameters. They may possess good electromagnetic compatibility, be able to work stably in complex electromagnetic environments, and reduce the impact of external interference on their performance. They have certain signal processing capabilities, and can analyze, convert, and process input signals to meet different control or monitoring requirements. They support multiple communication protocols, making it convenient to integrate with other devices or systems and interact with data, and enabling more complex automation control solutions. Technical Specification Parameters: Operating Voltage: 220V Output Frequency: 60KHz Ambient Temperature: -40°C - 120°C Ambient Humidity: 15% Dimensions: Length 545mm, Width 150mm, Height 74mm Weight: 1.08kg Input Points: 1500 Output Points: 1500 Current: 2.2A Voltage: 200V

Application Areas Industrial Automation: In various industrial production processes, it can be used for monitoring and controlling key parameters. For example, in chemical production, it can precisely control parameters such as the temperature and pressure of the reaction kettle to ensure the safety of the production process and the stability of product quality. In steel plants, it can be used to control the feeding of the blast furnace, temperature regulation, and the monitoring of equipment operation status. Power System: It can be applied in places such as substations and power plants, and can perform high-precision measurement and analysis of parameters such as voltage, current, and power in the power system, providing important data support for the stable operation and protection of the power system. For example, it can be used to monitor the operation parameters of the transmission line and promptly detect and warn of potential faults. Smart Building: In the smart building system, it can be used for monitoring and controlling the air conditioning system, lighting system, elevator system, etc. For instance, it can automatically adjust the operation mode of the air conditioner according to the indoor and outdoor environmental parameters to achieve energy-saving management; it can perform intelligent control of the lighting system and automatically adjust the brightness according to different scenarios and times. Transportation: In the field of rail transit, it can be used in the control system of trains to precisely control the running speed, position, braking, etc. of the train to ensure the safe operation of the train. In electric vehicle charging facilities, it can monitor and manage the charging process to achieve efficient and safe charging.

Common Faults and Solutions:

Power Supply Fault

Fault Phenomenon: The device cannot start, and the power indicator light does not turn on.

Possible Reasons: Power input fault, such as the power cord not being properly plugged in, the power switch not being turned on, or the fuse being blown; the power module being damaged.

Solutions: Check whether the power cord is firmly connected, turn on the power switch, and check whether the fuse is blown. If the fuse is blown, replace it with a fuse of the same specification. If all the above checks are normal, the power module may be damaged, and professional maintenance personnel should be contacted for repair or replacement of the power module.

Communication Fault

Fault Phenomenon: It cannot communicate normally with other devices or systems, and communication error prompts or data transmission interruptions occur.

Possible Reasons: Incorrect communication parameter settings, such as inconsistent settings of the baud rate, communication protocol, IP address, etc.; poor connection of the communication line, such as a loose network cable or a damaged serial port cable; the communication interface being damaged.

Solutions: Check the communication parameter settings to ensure they are consistent with those of other devices. Check the connection of the communication line, re-plug the network cable or serial port cable, and replace it if it is damaged. If the communication interface is damaged, professional personnel should be engaged for repair or replacement.

Input and Output Fault

Fault Phenomenon: The input signal cannot be correctly received, or the output signal is abnormal. For example, the sensor input signal is normal, but the device does not respond accordingly, or the output control signal cannot drive the external device.

Possible Reasons: The input and output interface is loose or damaged; the input and output module is faulty; the external device is malfunctioning.

Solutions: Check the connection of the input and output interface to ensure it is secure. If the interface is okay, try replacing the input and output module for testing. At the same time, check whether the external device is working properly, such as whether there are faults in the motor, valve, etc.

Over-temperature Fault

Fault Phenomenon: Overheat protection occurs during the operation of the device, and the temperature indicator light turns on or the device automatically shuts down.

Possible Reasons: The ambient temperature is too high; the device has poor heat dissipation, such as a malfunctioning cooling fan or a blocked radiator; a fault in the internal components of the device leads to excessive power consumption.

Solutions: Improve the installation environment of the device, lower the ambient temperature, and ensure that there is sufficient ventilation space around the device. Check whether the cooling fan is operating normally and clean the dust and debris on the radiator. If the above measures are ineffective, there may be a fault in the internal components of the device, and professional personnel should be called for inspection and repair.

Software Fault

Fault Phenomenon: The device runs unstably, and situations such as freezing, program errors, or abnormal functions occur.

Possible Reasons: Incompatible software version; damaged or lost program files; software errors caused by illegal operations.

Solutions: Check the software version and update it to the latest compatible version if necessary. Try reinstalling or restoring the program files. At the same time, standardize the operation process to avoid illegal operations. If the software fault persists, ABB technical support personnel should be contacted for further diagnosis and handling.