Description

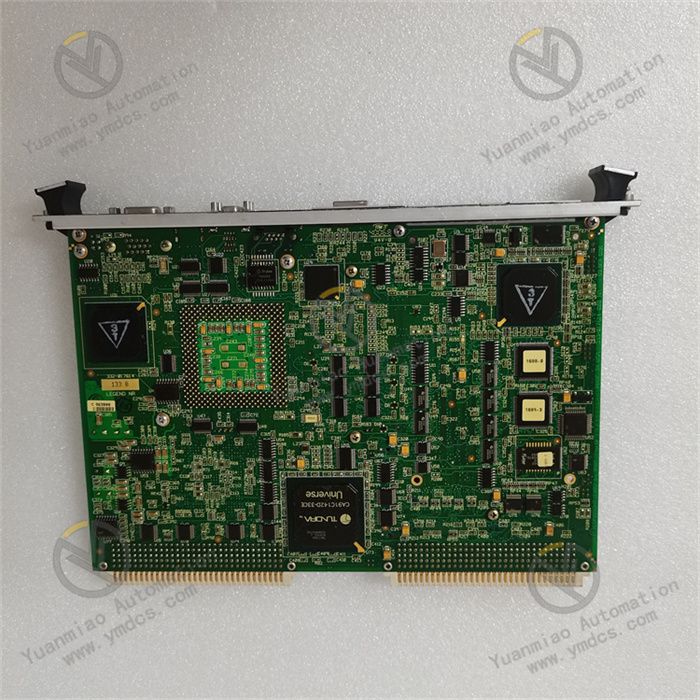

GE IS215UCVEH2AF

The GE IS215UCVEH2AF is a control module that belongs to the key component system of the GE Speedtronic series control systems. It is custom-developed for control scenarios of core power equipment such as gas turbines, steam turbines, combined cycle generator sets, and large industrial turbomachinery. Its applications cover critical industrial fields with strict requirements for control accuracy, operational reliability, and real-time responsiveness—including power generation, petrochemicals, metallurgical energy, and heavy manufacturing. It serves as the core control hub for ensuring the safe, efficient, and continuous stable operation of large-scale power equipment throughout its lifecycle.

The core functions of this module focus on multi-dimensional signal accurate acquisition, efficient logical operation, and precise control command output:

- Through integrated multi-type I/O channels, it collects real-time sensor signals (e.g., temperature, pressure, vibration, and rotational speed) from the field.

- After receiving instructions from the upper-level control system, its built-in high-performance multi-core embedded control unit and dedicated control algorithms perform signal conditioning, closed-loop regulation, logical interlocking, and fault prediction.

- Finally, it outputs control commands to achieve precise management of the entire process of equipment start-up, load adjustment, operation monitoring, and shutdown protection.

Additionally, the module features comprehensive fault diagnosis, massive data storage, and multi-protocol interaction capabilities, enabling seamless collaboration with upstream and downstream systems.

In terms of hardware architecture and environmental adaptability:

The module adopts a standardized modular design of the GE Speedtronic series, allowing direct and seamless integration into mainstream GE control systems such as Mark VI, Mark VIe, and Speedtronic—no additional adapter modules or custom drivers are required for high-speed data exchange with power modules, communication expansion modules, and I/O sub-modules in the system.

- Compliant with industrial-grade extreme environment design specifications, it undergoes multiple electromagnetic compatibility (EMC) optimizations, wide temperature range adaptability enhancements, redundant design for critical circuits, and structural reinforcement. This enables stable operation in harsh industrial on-site environments characterized by high temperature, high humidity, dust, strong vibration, intense electromagnetic radiation, and voltage fluctuations.

- Leveraging GE's proprietary 32-bit multi-core embedded control chip and real-time operating system kernel, it achieves microsecond-level response and high-precision execution of control commands, providing solid technical support for the complex control needs of large-scale power equipment.

The module adopts unified hardware interface specifications and communication protocol stacks of the GE Speedtronic series. It can be directly inserted into standard chassis of systems like Mark VI and Mark VIe. After power-on, it automatically completes communication handshaking, parameter synchronization, and identity authentication with the system's main controller, power modules, and I/O expansion modules via the chassis backplane high-speed bus (rate ≥2Gbps), enabling "plug-and-play" rapid integration.

It supports full graphical programming with mainstream configuration software such as GE Proficy iFIX, CIMPLICITY, and Intellution FIX—allowing intuitive configuration of control logic, I/O channel mapping, PID parameter tuning, alarm threshold setting, and redundancy strategy setup without additional dedicated driver development.

Data interaction delay with other system components is ≤0.2ms, ensuring real-time synchronization of control commands and monitoring data. This shortens the integration and commissioning cycle by over 40% compared to traditional modules, significantly reducing engineering implementation costs.

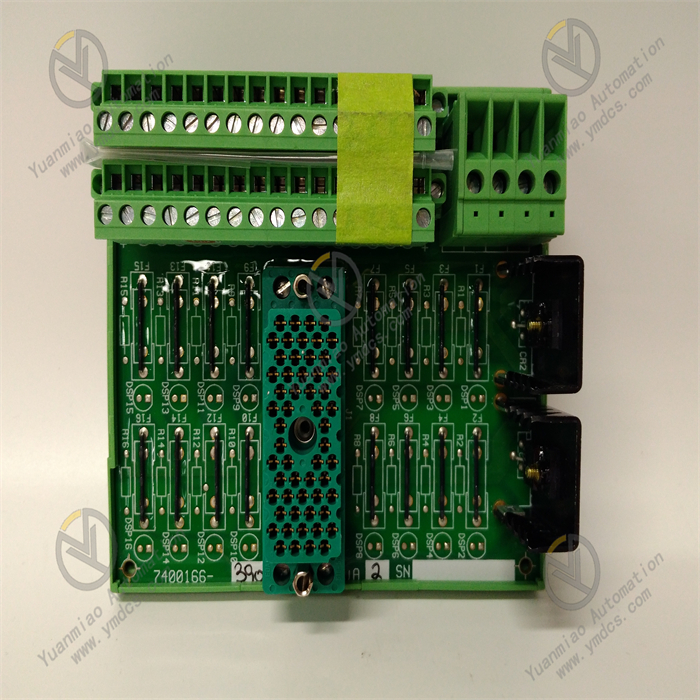

The module integrates 16 analog input channels, 10 analog output channels, 24 digital input channels, 14 digital output channels, and 6 pulse input channels. It can fully access multi-type on-site signals—including sensor signals (temperature, pressure, vibration, displacement, rotational speed, flow, liquid level) and actuator control signals (solenoid valves, control valves, contactors, frequency converters)—enabling full-range data acquisition and multi-dimensional precise control of power equipment operation parameters.

- Analog channels: Input accuracy up to ±0.02%FS, output accuracy ±0.04%FS, capable of capturing subtle parameter fluctuations (minimum detectable signal change of 0.01%FS).

- Digital channels: Support adaptive switching between dry/wet contacts without hardware jumper adjustment, adapting to different on-site wiring scenarios.

- Pulse channels: Support 0~30kHz wide-frequency signal input, enabling direct connection to speed sensors for high-precision speed measurement (±0.05rpm).

All channels feature independent calibration functions, supporting online single-point calibration without overall shutdown—greatly improving system maintenance convenience.

Equipped with GE's proprietary 32-bit 3-core embedded control processor (1GHz clock speed), it adopts a 3-core parallel architecture ("signal processing - operation control - communication management"). Each core operates independently and shares data in real time via a high-speed internal bus, with an operation cycle ≤0.2ms—enabling rapid processing of multi-channel concurrent signals and execution of complex control logic.

- Analog input response time ≤0.4ms; digital input response time ≤0.2ms; output command delay ≤0.6ms. It can promptly capture minor changes in equipment operation status and output precise control commands, making it ideal for scenarios requiring ultra-high real-time performance—such as gas turbine speed regulation (control accuracy ±0.08rpm), steam pressure closed-loop control (accuracy ±0.008MPa), and turbomachinery load precise adjustment.

It supports multiple complex algorithms (PID regulation, fuzzy control, adaptive control, predictive control, MPC), which automatically optimize control parameters based on equipment operating conditions. This adapts to high-precision control needs under different loads and working conditions, especially improving control accuracy by over 20% in variable working condition scenarios.

The module supports 1:1 dual-module hot redundancy. The master and backup modules achieve real-time synchronization of input signals, operation logic, output status, alarm information, and configuration parameters via a dedicated high-speed synchronization bus (synchronization rate ≤500ns). During operation, they continuously perform mutual health status checks, data verification, and clock synchronization.

If the master module fails (e.g., processor fault, I/O channel abnormality, communication interruption, power fluctuation, heat dissipation failure), the backup module automatically takes over control tasks without disturbance within ≤1.5ms. The switching process ensures no control command interruption, no output parameter fluctuation, and no impact on equipment operation—guaranteeing continuous stable operation of power equipment (annual fault downtime ≤0.5 hours).

The module has built-in comprehensive fault diagnosis and fault-tolerance mechanisms, which perform real-time monitoring of critical components (core processor, memory, I/O channels, communication interfaces, power circuits, heat dissipation system). Upon detecting a fault, it immediately triggers local LED indicator alarms, uploads detailed fault codes, and automatically initiates redundancy switching. The system’s mean time between failures (MTBF) is ≥120,000 hours.

It features 5-level alarms (Informational, Attention, Warning, Severe, Critical) and interlock protection functions. Based on power equipment operation protocols, it allows presetting of fault alarm thresholds and interlock logic for scenarios such as over-temperature, over-pressure, over-speed, over-vibration, low oil pressure, low water level, and abnormal flow.

- Informational threshold: Only uploads informational data (including parameter value and timestamp) to the upper system.

- Attention threshold: Triggers local green indicator flashing.

- Warning threshold: Illuminates local yellow warning indicator and triggers audible-visual alarms in the upper system.

- Severe threshold: Outputs load reduction control commands and enhances alarms (dual on-site + remote alarms).

- Critical threshold: Immediately outputs interlock commands (emergency shutdown, fuel cutoff, main valve closure, excitation cutoff), locks fault status, records fault data, and uploads detailed alarm information—preventing fault escalation from the source.

It supports storage and traceability of 500,000 historical alarm data entries (recording alarm time, parameter values, fault types, handling results, and operation logs), providing reliable basis for fault troubleshooting and root cause analysis. The alarm logic supports 0~60s delay anti-jitter configuration, effectively filtering false alarms caused by transient interference (false alarm rate <0.1%).

Equipped with 2 RS485, 2 Gigabit Ethernet, 1 CANopen, and 1 PROFINET communication interfaces, it supports mainstream industrial communication protocols (Modbus RTU/ASCII, GE Proficy, EtherNet/IP, Modbus TCP, CANopen, PROFINET). This enables seamless data interaction with upper monitoring systems, HMI, SCADA systems, PLCs, data servers, and cloud platforms.

- Via the Gigabit Ethernet interface, remote monitoring and maintenance are achievable: maintenance personnel can complete module program downloading, parameter modification, fault diagnosis, data backup, and firmware upgrading in the central control room—no on-site operation required, improving maintenance efficiency by over 50%.

It supports multi-module networking communication, enabling the construction of distributed control systems (DCS) or edge computing nodes. This realizes collaborative control and centralized management of multiple power equipment in large industrial sites, adapting to the control needs of complex production processes.

The communication process adopts CRC32 data verification, timeout retransmission, link redundancy, and fault-tolerance mechanisms—ensuring data transmission reliability (transmission error rate ≤10⁻¹⁰).

It adopts a 4-layer electrical isolation design ("input-output", "input-power", "inter-channel", "communication-power") with a maximum isolation voltage of 4000VAC/1min. This effectively blocks the impact of on-site ground loops, power fluctuations, equipment electromagnetic radiation, and communication interference on the module.

Built-in high-performance EMC filter circuits, surge suppression components, ESD protection circuits, and full-metal RF interference shielding layers enable it to withstand ±15kV ESD shocks, ±5kV surges, and ±2kV pulse bursts. Compliant with IEC 61000-4-2/3/4/5/6/8 EMC immunity standards, it maintains stable operation in high-interference environments (e.g., high-voltage frequency converters, high-power motors, high-frequency heating equipment, high-voltage transmission lines) with RF interference suppression ≥70dB.

Sensor input and output interfaces use dedicated shielding designs; when paired with dedicated shielded cables, anti-interference performance is further enhanced—ensuring signal transmission stability and accuracy.

Constructed with industrial-grade high-reliability components (military-grade capacitors, automotive-grade high-temperature chips, long-life relays) and an integrated die-cast aluminum alloy housing. The housing surface undergoes anodization, anti-corrosion coating, and sandblasting—providing excellent heat dissipation, dust resistance, oil resistance, corrosion resistance, and impact resistance.

The internal optimized heat dissipation structure is equipped with high thermal conductivity heat sinks and intelligent temperature-controlled fans (auto on/off within 45~75℃, with speed adjustment). This rapidly dissipates heat from core components, ensuring continuous stable operation of the module within the standard temperature range of -35~80℃.

It passes IEC 60068-2-6 vibration tests (5~200Hz, 8g acceleration) and IEC 60068-2-27 shock tests (30g acceleration, 11ms duration), adapting to strong vibrations during equipment operation and severe impacts during transportation/installation. With an IP20 protection rating, it is equipped with dust-proof panels, waterproof aviation connectors, and cable glands—effectively blocking dust, oil, and moisture in industrial sites. It also supports operation in salt spray environments (compliant with IEC 60068-2-11), adapting to harsh operating conditions of high dust, high temperature, high humidity, high vibration, and high corrosion.

![]()