Description

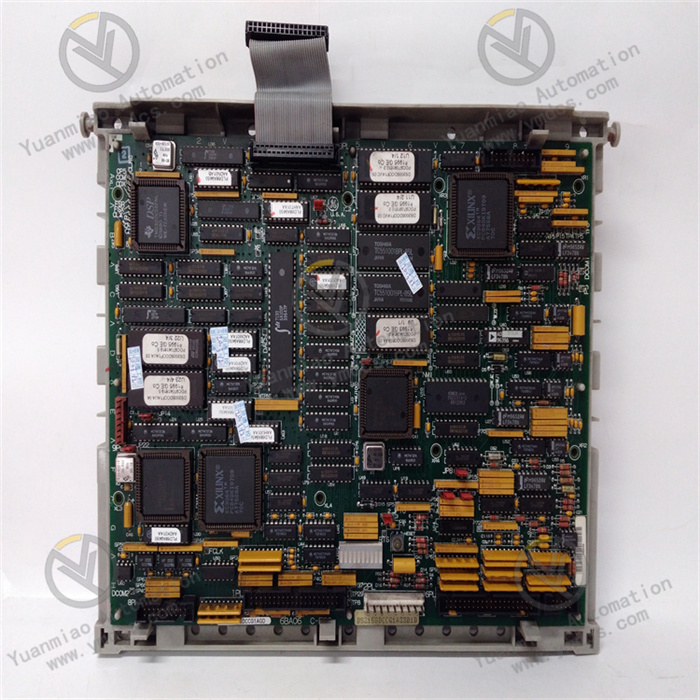

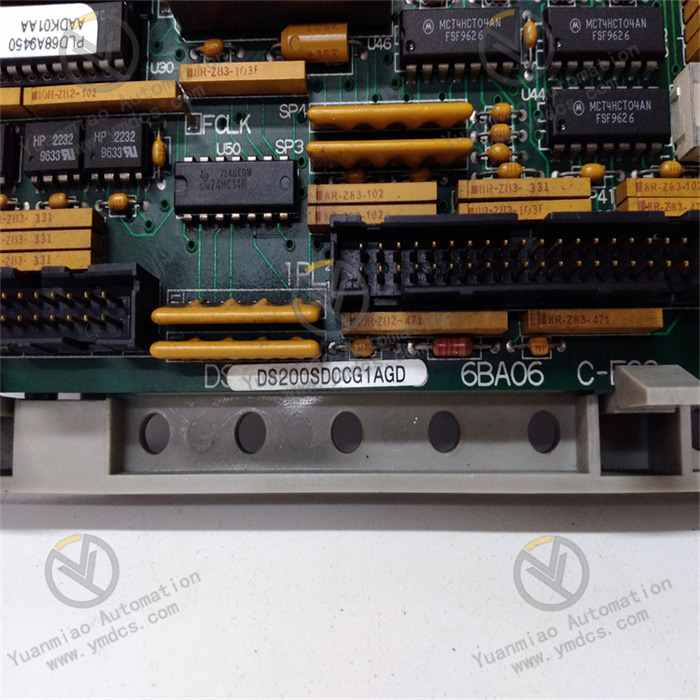

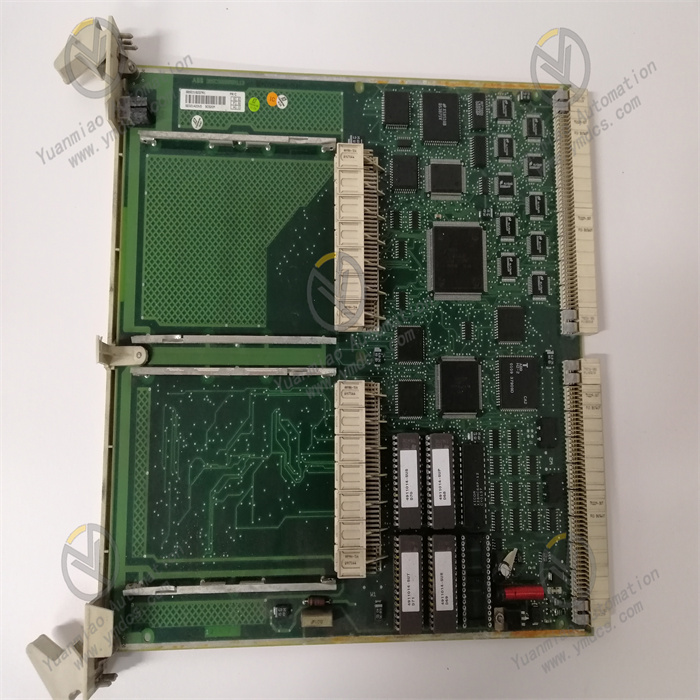

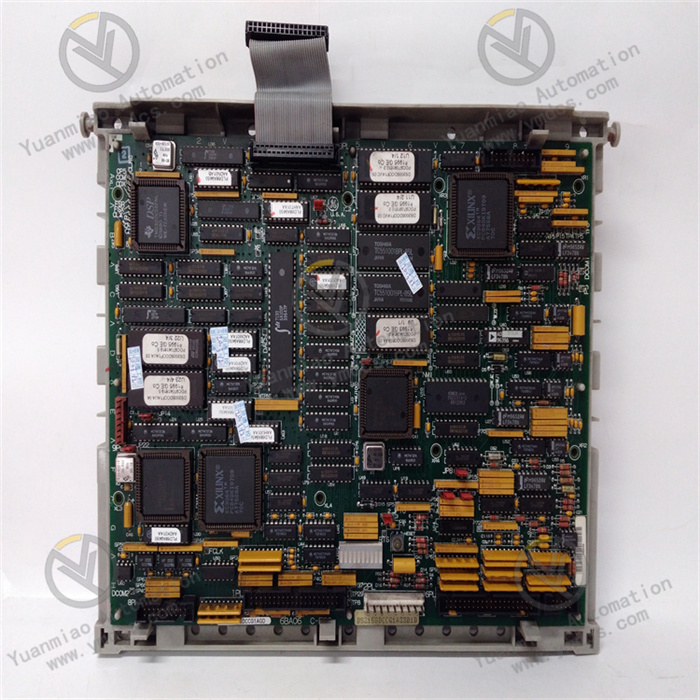

GE DS200SDCCG1AGD

The GE DS200SDCCG1AGD is a high-performance drive control module developed by General Electric (GE), specializing in industrial automation and motor control systems. As a core component of GE's classic DS200 series, this module integrates advanced digital signal processing (DSP) technology and a robust hardware architecture, serving as a critical interface for precise regulation of motor speed, torque, and position in complex industrial scenarios such as power generation, manufacturing, and process control.

- Input Voltage: 24V DC (±10% tolerance)

- Output Voltage: 0-10V DC (analog) / 24V DC (digital)

- Power Consumption: ≤20W

- Control Channels: 8 analog inputs / 16 digital I/O channels

- Communication Interfaces: RS485 (Modbus RTU), Ethernet (Modbus TCP/IP), CANopen

- Frequency Response: 0-20kHz

- Control Accuracy: Speed: ±0.1% / Torque: ±2%

- Operating Temperature: -40°C to +70°C

- Storage Temperature: -55°C to +85°C

- Humidity: 5%-95% (non-condensing)

- Protection Level: IP20

- Dimensions: 170mm × 100mm × 50mm

- Weight: Approximately 1.2kg

Supports vector control and V/F control modes, adapting to various motor types (AC induction, DC, servo) for smooth speed regulation and stable torque output under variable loads, optimizing energy efficiency in industrial applications.

Equipped with multi-protocol compatibility (Modbus, CANopen, etc.), it enables seamless integration with PLCs, SCADA systems, and HMIs, facilitating real-time data exchange and remote monitoring in complex automation networks.

Built-in overvoltage, overcurrent, short-circuit, and overheat protection functions automatically trigger fault alarms and power cutoff to prevent equipment damage, enhancing system reliability.

Standardized architecture allows quick replacement of faulty modules, minimizing downtime. It supports hardware expansion (e.g., additional I/O modules) to adapt to evolving production requirements.

- Mount the module on a DIN rail or control panel with power off.

- Connect 24V DC power supply to the designated terminals, ensuring correct polarity.

- Use shielded cables for analog/digital I/O connections to reduce interference.

- Use GE's dedicated software (e.g., Proficy Machine Edition) to set parameters via RS485 or Ethernet.

- Configure control modes (vector/V/F), communication protocols, and I/O mapping based on application needs.

- Power on the system and check status LEDs: green for normal operation, red for faults.

- Perform initial motor testing with low-speed commands to verify speed and torque response.

- Regularly clean the module's heat sink to prevent dust accumulation.

- Monitor input voltage stability and check for loose terminal connections.

- Update firmware periodically via GE's official platform for optimal performance.

- Refer to front-panel LED fault codes (e.g., E010 for overcurrent) and follow troubleshooting steps in the manual.

- Contact GE technical support with fault logs for persistent issues.

![]()