Description

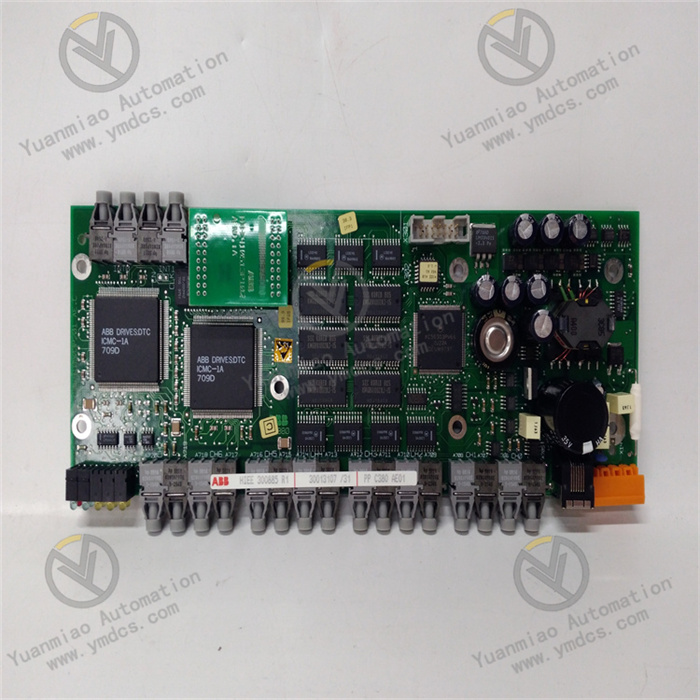

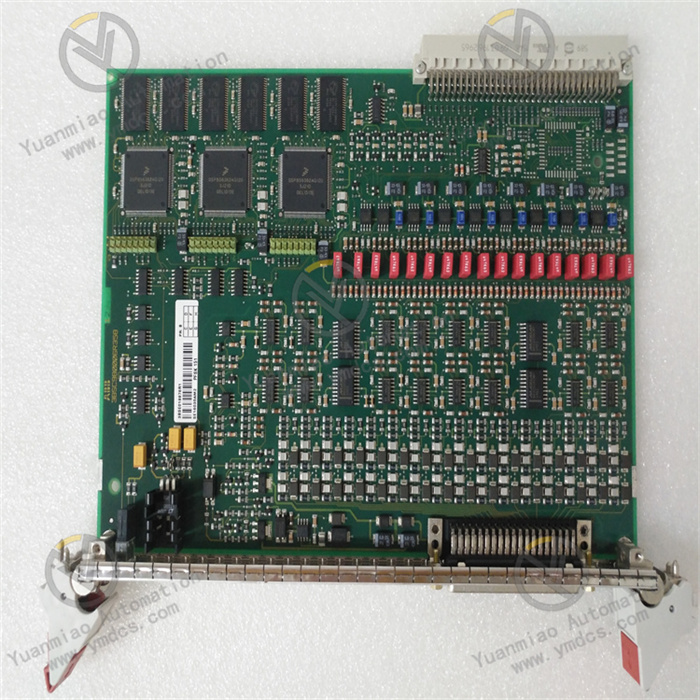

Functional Features 1. Strong data processing capability: Equipped with a high-performance processor, it can quickly process various data from industrial sites, including analog quantities and digital quantities, and achieve real-time monitoring and control of industrial processes. For example, in an automated production line, it can quickly analyze and process data transmitted by various sensors, and adjust parameters in the production process in a timely manner. 2. Multiple communication interfaces: It supports various communication protocols such as Ethernet and Profibus, making it convenient to transmit data and communicate with other devices (such as PLCs, host computers, sensors, actuators, etc.). It can upload the operating data of the device to the monitoring system in real time and receive control instructions to achieve remote monitoring and control. 3. Rich I/O functions: It has a rich variety of input and output interfaces, including analog input and output, digital input and output, etc. It can be connected to various industrial devices, such as sensors and actuators, to achieve comprehensive control of industrial processes. For example, it can collect parameters such as temperature and pressure through analog input interfaces and control the start and stop of motors through digital output interfaces. 4. Reliable stability: It uses high-quality electronic components and advanced manufacturing processes, and has strong anti-interference ability. It can operate stably in harsh industrial environments (such as high temperature, high humidity, strong electromagnetic interference, etc.). It has a complete self-diagnosis function, which can detect device failures in a timely manner and take corresponding measures to ensure the reliability of the system. 5. Flexible programming function: It supports multiple programming languages, such as ladder diagram and structured text, etc., making it convenient for engineers to program according to different application requirements. Users can write control programs according to the requirements of the actual production process to achieve precise control of the device.

Technical Parameters 1. Power supply voltage: Usually powered by a DC power supply, such as 24V DC, and may also support AC power supply, depending on the product specifications. Processor performance: The processor has a relatively high main frequency and a large memory capacity, which can meet the requirements of data processing and program operation. For example, the main frequency of the processor can reach several hundred MHz, and the memory capacity may range from several MB to dozens of MB. 2. Communication rate: The Ethernet communication rate can reach 10/100Mbps, and the serial communication rate can be between 9600bps and 115200bps to meet different communication needs. 3. Number of I/O channels: There are a large number of analog input and output channels as well as digital input and output channels, and the specific numbers may vary depending on the model. For example, there may be 8 analog input channels, 4 analog output channels, and 16 digital input and output channels, etc. 4. Operating temperature range: The general operating temperature range is from -10°C to 55°C, which can adapt to different industrial environment temperatures. Application Areas 1. Power industry: It is used for the control and monitoring of equipment in substations, such as the temperature monitoring of transformers and the control of circuit breakers, etc., to ensure the stable operation of the power system. In the power distribution system, it can monitor and control power parameters in real time to achieve reasonable power distribution. 2. Oil and gas: In oil and gas extraction, transportation and processing equipment, such as compressors and pumps, it can monitor and control the operating status of the equipment in real time. It can precisely control the operating status of the equipment according to the process requirements to improve production efficiency and safety. 3. Industrial automation production lines: In the automation production lines of industries such as automotive manufacturing and electronics manufacturing, it can precisely control production equipment to achieve the automation and intelligence of the production process, and improve production efficiency and product quality. 4. Smart buildings: It participates in the automation control systems of smart buildings, monitors and controls systems such as air conditioning systems, lighting systems, and elevator control systems to achieve intelligent management of the building and energy optimization.

Common Faults and Solutions 1. Communication faults Reasons: Damaged communication cables, loose communication interfaces, incorrect communication parameter settings, communication module failures, etc. Solutions: Check whether the communication cables are properly connected and if there is any damage, and replace the cables if there are problems; check whether the communication interfaces are loose and re-plug them; confirm whether the communication parameter settings, such as baud rate, data bits, stop bits, etc., are correct, and re-set the correct parameters; if the communication module is suspected to be faulty, use professional detection equipment for detection and replace the module if there are problems. 2. I/O faults Reasons: Damaged input and output modules, sensor failures, actuator failures, incorrect wiring, etc. Solutions: Check whether the input and output modules have phenomena such as overheating and damage, and replace the faulty modules; check whether the sensors and actuators are working properly, and replace the corresponding devices if there are problems; check whether the wiring is correct and repair the incorrect wiring. 3. Program operation faults Reasons: Program logic errors, insufficient memory, processor failures, etc. Solutions: Check the program logic, debug the program, and repair the logic errors; check the memory usage, optimize the program, and release the memory; if the processor is suspected to be faulty, use professional detection equipment for detection and replace the processor if there are problems. 4. Power supply faults Reasons: Damaged power supply modules, abnormal power input (such as unstable voltage, reverse polarity, etc.). Solutions: Check whether the power supply modules have phenomena such as overheating and damage, and replace the faulty power supply modules; check whether the power input voltage is within the allowable range of the equipment and whether the power polarity is correct to ensure normal power input.

ABB Related Products

| PU518 3BSE018680R1 | PP846 3BSE042238R1 |

| PU514A 3BSE032400R1 | PP836A 3BSE042237R2 |

| PU515A 3BSE032401R1 | PP826A 3BSE042244R2 |

| PU516A 3BSE032402R1 | PP835A 3BSE042234R2 |

| PU512V1 3BSE004736R1 | PP846A 3BSE042238R2 |

| PU512V2 3BUR001401R1 | PP865A 3BSE042236R2 |

| PU513V2 3BSE013034R1 | PP877K 3BSE069274R1 |

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage