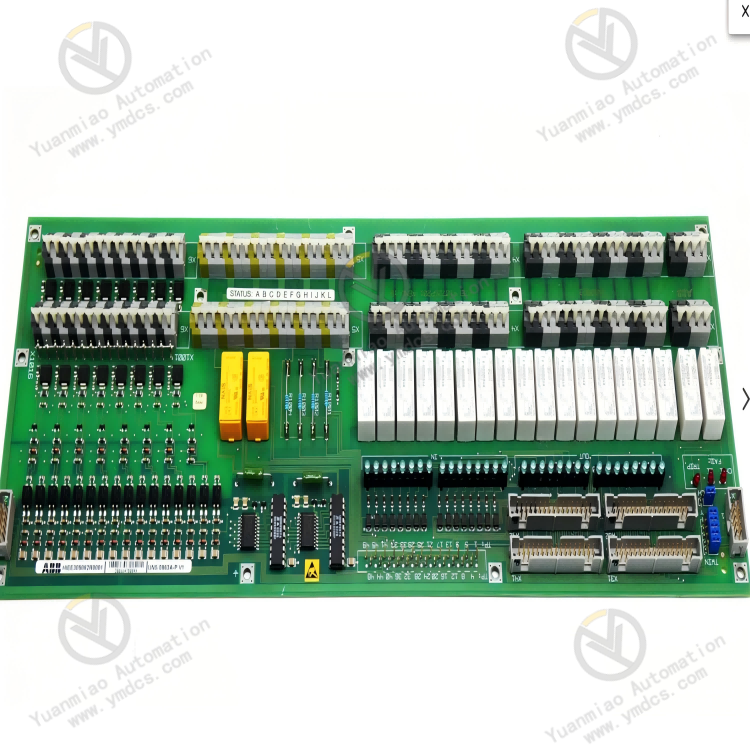

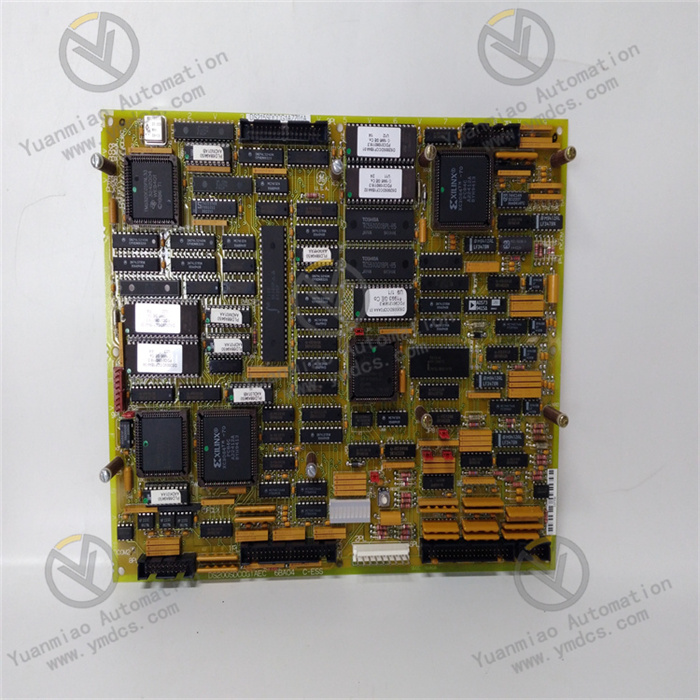

Description

Honeywell 51405040 - 175 may be a module or component with a specific function in Honeywell's industrial automation or control system, used to achieve specific industrial control, monitoring or communication functions. It typically plays a role in distributed control systems (DCS), programmable logic controller (PLC) systems or other industrial automation architectures. Functional Features Signal Processing Function: It may have the ability to collect, process and convert input analog or digital signals. For example, it can amplify, filter and perform analog-to-digital conversion on weak electrical signals from field sensors, so that the control system can recognize and process these signals. Communication Function: It supports data communication with other devices or systems and may be compatible with a variety of industrial communication protocols, such as Modbus, Profibus, Ethernet/IP, etc. This enables it to be integrated with devices from different manufacturers, achieve data interaction and sharing, and facilitate the construction of complex industrial automation networks. Control Logic Execution: It may have certain control logic built-in, which can judge input signals according to preset rules and output corresponding control instructions. For instance, when it detects that a certain process parameter exceeds the set threshold, it will automatically trigger an alarm or control the actions of relevant devices to ensure the safety and stability of the production process. Diagnosis and Self-protection Function: It has a certain fault diagnosis capability and can monitor its own working status in real time. When abnormal situations (such as hardware failures, communication interruptions, etc.) are detected, it will promptly send out alarm signals and take corresponding protective measures, such as automatically switching to the standby mode or stopping relevant operations to prevent the expansion of faults.

Technical Parameters

Power Supply Parameters: It usually uses a DC power supply, and the possible voltage range is between 18V DC and 30V DC to ensure stable operation in an industrial environment and has a certain ability to resist power fluctuations.

Input and Output Characteristics:

Input Types: It may support various input types, such as analog inputs (such as 4 - 20mA, 0 - 10V, etc.) and digital inputs (such as dry contacts, wet contacts, etc.). The number and accuracy of input channels will vary according to specific product specifications.

Output Types: Correspondingly, the outputs may also include analog outputs (used to control devices such as control valves) and digital outputs (used to drive relays, contactors, etc.). The load capacity and accuracy of the outputs are also important technical indicators.

Operating Temperature and Humidity Range: To adapt to the industrial environment, the operating temperature range may be between -20°C and 60°C, and the relative humidity range is between 5% and 95% (non-condensing) to ensure normal operation under different environmental conditions.

Communication Rate: If it supports the communication function, the communication rate will vary according to the communication protocol and interface type used. For example, the Ethernet communication rate may reach 10/100Mbps, while the serial communication rate may be between 9600bps and 115200bps.

Application Areas

Industrial Automation Production Lines: In the automation production lines of industries such as automobile manufacturing, electronics manufacturing, and mechanical processing, it is used to monitor the operating status of equipment, control the production process, and realize operations such as material transportation and processing, improving production efficiency and product quality.

Process Industry: Such as the chemical, petroleum, power, and metallurgy industries, it is used to monitor and control parameters such as temperature, pressure, flow rate, and liquid level in the production process in real time to ensure the safe, stable and efficient operation of the production process.

Intelligent Buildings: In intelligent building systems, it can be used to achieve intelligent control and management of equipment such as air conditioning systems, lighting systems, elevator systems, and security systems, improving the energy efficiency and comfort of the building.

Energy Management Systems: Applied in the fields of energy production, transmission and distribution, it monitors and analyzes energy consumption to achieve optimized energy management and energy conservation and emission reduction.