Description

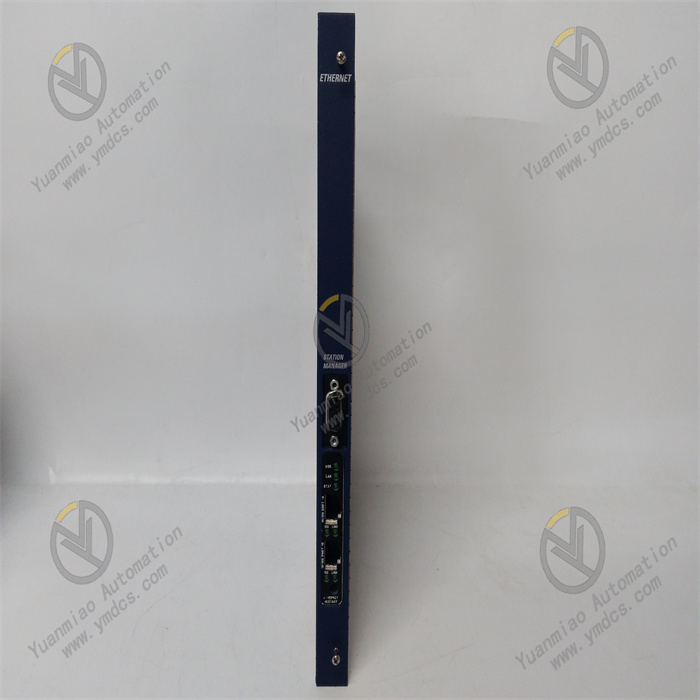

GE Fanuc IC698ETM001

I. Overview

GE Fanuc IC698ETM001 is a high-performance industrial Ethernet communication module specifically designed for the RX3i series PLC systems. Its core positioning is to serve as an "Industrial Ethernet Interaction Hub", focusing on addressing the high-speed data interaction needs between PLC systems and HMIs, SCADA systems, MES systems, as well as other intelligent devices in industrial scenarios. Through multi-protocol compatibility, Gigabit Ethernet transmission, and high-reliability design, it enables seamless connection between PLC systems and industrial networks, supporting networked monitoring and collaborative control of small and medium-sized industrial automation systems.

This module boasts core advantages of "multi-protocol compatibility + high-speed transmission + strong environmental resistance":

- It supports mainstream industrial Ethernet protocols such as EtherNet/IP, Modbus TCP, and PROFINET (requires firmware upgrade), enabling cross-system compatibility with devices from brands like Rockwell and Siemens.

- Equipped with one Gigabit Ethernet port (10/100/1000Base-T), it achieves a maximum data transmission rate of 1Gbps, meeting the demand for high-speed interaction of large-volume data (e.g., production reports, historical trends).

- Meanwhile, it features wide temperature adaptability (0℃~+60℃), electromagnetic interference resistance, and oil/dust-proof design, allowing continuous and stable operation in complex industrial environments such as automobile manufacturing, food and beverage production, and electronic equipment assembly.

Compared with ordinary 100Mbps Ethernet modules (e.g., IC698ETC001), it has significant advantages in transmission rate and protocol compatibility. Compared with third-party communication gateways, it is natively compatible with RX3i series PLCs and supports plug-and-play functionality without complex configuration, making it a key component for building networked control systems of RX3i series PLCs.

As a mainstream communication module in the RX3i series, IC698ETM001 is widely used in scenarios such as auto parts welding lines, food filling production lines, and electronic component testing equipment. It provides core support for Ethernet communication between PLC systems and upper computers, intelligent instruments, and industrial robots, and is a key technical equipment for improving industrial production transparency, enabling remote monitoring and operation & maintenance, and ensuring system collaboration efficiency.

II. Technical Specifications

(I) Core Communication and Protocol Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Communication Port and Rate | 1 Gigabit Ethernet port (10/100/1000Base-T, RJ45 connector), supporting auto-negotiation (rate/duplex mode); supports MDI/MDI-X auto-crossover, no crossover cable required; data transmission rates: 10Mbps (half-duplex/full-duplex), 100Mbps (half-duplex/full-duplex), 1000Mbps (full-duplex) |

| Protocol Compatibility | Natively supports EtherNet/IP (adapter/scanner mode) and Modbus TCP (client/server mode); supports PROFINET IRT (requires firmware upgrade to V2.0 or above) and TCP/IP (IPv4/IPv6 dual stack); compatible with OPC UA protocol (requires matching OPC server software) to realize data interaction with MES/ERP systems |

| Connection Capacity | Maximum number of simultaneous TCP connections: 64 (EtherNet/IP + Modbus TCP); supports scanning of up to 32 EtherNet/IP slave devices; supports up to 16 client connections in Modbus TCP server mode and up to 8 server connections in client mode |

| Data Interaction Performance | At 1000Mbps rate, the transmission delay of a single data frame (1500 bytes) is ≤1ms; supports Maximum Transmission Unit (MTU) of 1500 bytes and Jumbo Frame (9000 bytes, requires switch support) to improve large-volume data transmission efficiency |

(II) Electrical and Power Parameters

- Power Requirements: Operating voltage is 24V DC (with wide adaptation range of 19.2V DC~28.8V DC), powered by the RX3i rack backplane; operating current ≤300mA (at 1000Mbps rate); power consumption ≤7.2W (powered by 24V DC under full-load condition); supports reverse power connection protection (no damage under reverse voltage ≤36V DC); built-in overcurrent protection (current limiting triggered when current exceeds 500mA).

- Electrical Isolation: The Ethernet port is optically isolated from the internal circuit of the module (isolation voltage ≥2500Vrms); dual isolation between the power circuit and communication circuit prevents ground loop interference and external voltage intrusion, protecting the PLC core circuit.

- EMC Compatibility: Complies with EN 61000-6-2 industrial immunity standard; Electrostatic Discharge (ESD) protection level: ±15kV (air)/±8kV (contact); Radio Frequency (RF) radiation immunity level: 10V/m (80MHz~1GHz); Electrical Fast Transient (EFT) immunity level: 2kV (power terminal)/1kV (signal terminal), preventing communication interruption caused by electromagnetic interference.

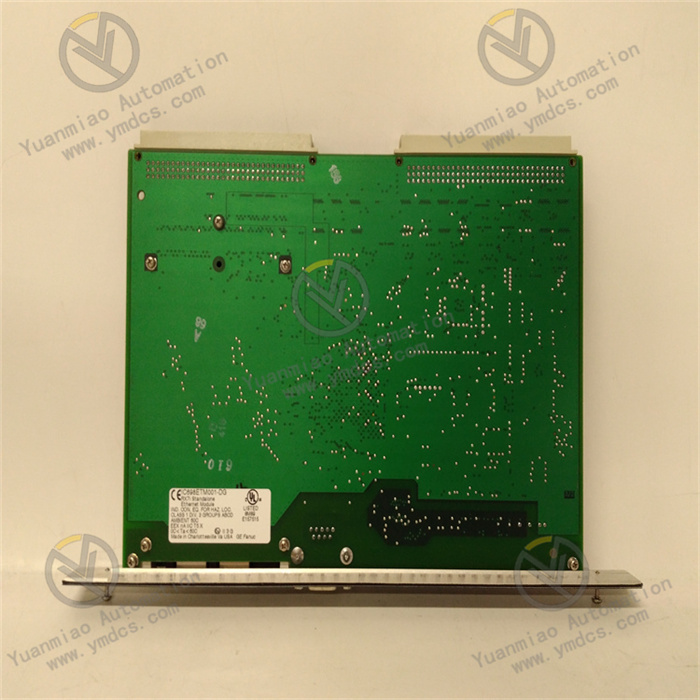

(III) Physical and Installation Parameters

- Physical Dimensions: Adopts the standard rack-mounted design of the RX3i series; dimensions (length × width × height) are 120mm×80mm×150mm, compatible with RX3i standard racks (e.g., IC698CHS010); can be installed side by side with CPU modules and I/O modules, saving control cabinet space.

- Installation Method: DIN rail mounting (compatible with DIN 35mm standard rails) or screw fixing; installation torque ≤2N・m to avoid damaging the module housing due to over-tightening; module weight ≤450g, lightweight design facilitating installation and maintenance.

- Indicator Configuration: The panel is equipped with 6 LED indicators (power, Ethernet link, Ethernet activity, EtherNet/IP status, Modbus TCP status, fault) to intuitively display communication status and fault types, enabling quick troubleshooting.

(IV) Environmental and Reliability Parameters

- Operating Environment: Operating temperature range: 0℃~+60℃; storage temperature range: -40℃~+85℃; humidity range: 5%~95% (non-condensing, complying with IEC 60068-2-3 standard); altitude ≤2000m (derating is required when exceeding this altitude, with communication rate derated by 10% for every 1000m increase).

- Vibration and Shock Resistance: Vibration resistance level: 5g (10Hz~500Hz, complying with IEC 60068-2-6); shock resistance level: 20g (11ms pulse, complying with IEC 60068-2-27), adapting to vibrations from workshop equipment and shocks during installation and maintenance.

- Reliability Index: Mean Time Between Failures (MTBF) ≥150,000 hours (per Telcordia SR-332 standard, under 25℃ environment); design life ≥10 years, reducing replacement frequency and maintenance costs.

III. Functional Features

(I) Multi-Protocol Compatibility for Cross-System Collaboration

With "native support for multiple protocols + cross-brand compatibility" as its core, GE Fanuc IC698ETM001 breaks down communication barriers between different industrial systems:

- Comprehensive Coverage of Mainstream Protocols: Natively supports EtherNet/IP and Modbus TCP, adapting to devices of different brands. For example, in an automobile welding workshop, the RX3i PLC connects 16 Rockwell PowerFlex inverters (EtherNet/IP slaves) through the module's EtherNet/IP scanner mode to realize real-time speed control of the inverters; meanwhile, it reads welding parameters (e.g., welding current, time) from 8 Siemens S7-1200 PLCs through the Modbus TCP client mode, enabling cross-brand device data interconnection.

- Flexible PROFINET Upgrade: Supports firmware upgrade to expand PROFINET IRT functionality, adapting to the Siemens ecosystem. For example, in electronic component testing equipment, after firmware upgrade, the module accesses the Siemens S7-1500 PLC system in PROFINET IRT slave mode and realizes real-time data interaction with the testing robot (PROFINET master) at a 1ms cycle, ensuring precise synchronization of testing actions.

- OPC UA Data Upload: Compatible with the OPC UA protocol (requires matching GE Fanuc Proficy OPC Server) to realize data interaction with MES systems. For example, in a food filling production line, the PLC uploads data such as "daily output (50,000 bottles)", "qualified rate (99.8%)", and "equipment failure rate (0.2%)" to the MES system through the module. The MES then generates production reports and equipment maintenance plans, improving management efficiency.

(II) Gigabit High-Speed Transmission for Improved Data Interaction Efficiency

Through the Gigabit Ethernet port and optimized data frame processing, the module realizes large-volume, low-latency communication:

- 1Gbps High-Speed Transmission: Compared with 100Mbps modules, its data transmission rate is increased by 10 times, adapting to large-volume data scenarios. For example, in lithium battery testing equipment, the PLC needs to transmit voltage and current waveform data of 16 testing channels to the HMI every 100ms (512 bytes per channel, totaling 8192 bytes). At the Gigabit rate, the transmission delay is ≤0.1ms, and the HMI displays waveforms in real time without lag; in contrast, the delay of a 100Mbps module is approximately 1ms, which is prone to data loss.

- Jumbo Frame Support: Supports 9000-byte Jumbo Frames, reducing the number of data frames and CPU processing load. For example, in an auto parts production line, the PLC uploads 1-hour production history data (approximately 10MB) to the MES system through the module. Only 12 data frames are needed when using Jumbo Frames, compared to 6900 frames for standard frames, reducing the CPU interrupt frequency by 99.8% and improving the PLC logic operation efficiency.

- Low-Latency Real-Time Communication: The data frame transmission delay at 1000Mbps rate is ≤1ms, meeting real-time control needs. For example, in a robot assembly workstation, the RX3i PLC sends action commands to 6 industrial robots through the module (once every 50ms, command length 64 bytes). The transmission delay is stably within 0.5ms, and the synchronization error of robot actions is ≤1ms, ensuring that the assembly accuracy meets standards.

(III) Industrial-Grade Protection for Adaptation to Complex On-Site Environments

In response to harsh conditions in industrial scenarios, the module features enhanced design in hardware durability and anti-interference capability:

- Wide Temperature and Humidity Adaptability: The operating temperature range of 0℃~+60℃ covers most industrial scenarios. For example, in an automobile workshop in southern China in summer (ambient temperature 55℃), the module operates for a long time without communication rate degradation, and the TCP connection stability is ≥99.99%; in a food cold storage in northern China in winter (ambient temperature 5℃), the module can start without preheating, and the Ethernet link establishment time is ≤2 seconds.

- Strong Electromagnetic Interference Resistance: The isolated Ethernet port and optimized EMC design resist industrial interference. For example, in a steel mill's rolling workshop (with high-power inverters and RF radiation of 20V/m), the Ethernet communication bit error rate between the module and HMI is ≤10⁻¹², with no data loss or communication interruption, ensuring real-time monitoring of rolling parameters.

- Oil and Dust Protection: The housing is made of ABS flame-retardant material with an IP20 protection level (when used with a control cabinet with IP54 level) to resist workshop pollutants. For example, in a mechanical processing workshop (with heavy oil and metal dust), the module's Ethernet port uses a dust-proof RJ45 connector, ensuring no terminal oxidation during long-term operation and a contact resistance ≤50mΩ for stable signal transmission; the cable connector adopts a waterproof design to prevent water ingress in humid environments during the rainy season.