Description

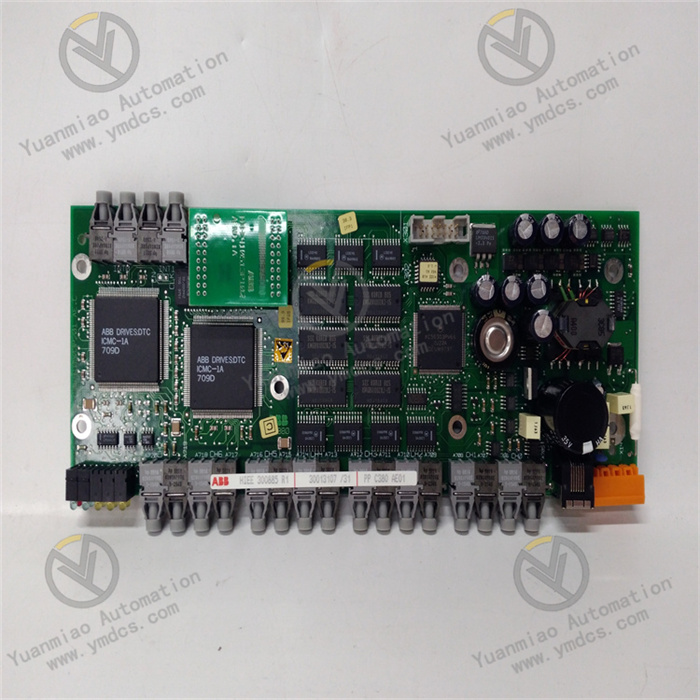

ABB PPC380AE01 HIEE300885R0001 is a control and drive board card applied to ABB equipment. Features Efficient and stable: Manufactured with advanced technologies and materials, it can achieve rapid response and precise control, providing reliable support for the control and drive of ABB equipment, and can operate stably in various environments and application scenarios. Strong compatibility: As a component of high-voltage frequency converters and other equipment, it has good compatibility with related equipment, ensuring the stable operation of the entire system. Rich in functions: It provides power outputs with multiple voltage and current levels, supports users in configuring the parameters and characteristics of the power output according to their needs. It is also equipped with power protection functions, such as overcurrent, overvoltage, and short-circuit protection, etc. At the same time, it has the ability to monitor the power status and can provide real-time feedback on the power quality and stability information. Technical Parameters Operating voltage: Usually 220V. Output frequency: Approximately 20. However, these parameters may vary depending on the specific application scenarios and configurations.

Application Scenarios Industrial automation control: Widely used in the automation control systems of ABB equipment, it can precisely control equipment such as motors, helping to improve production efficiency, reduce energy consumption, and extend the service life of the equipment. High-voltage frequency conversion system: As an important component of high-voltage frequency converters, it is used to control and regulate the operation of high-voltage frequency converters, providing stable power drive and control for various high-voltage motors and equipment, and is commonly found in industries such as power, chemical, metallurgy, and mining. Common Faults and Solutions Power supply fault Fault phenomenon: The board card cannot work normally. It may be due to abnormal power output, such as no voltage output, unstable output voltage, or exceeding the normal range, etc., resulting in the equipment controlled by it being unable to start or operate stably. Solution: Check whether the power input is normal, including whether the power cord connection is firm and whether the input voltage is within the specified range of the board card. If the input is normal, it may be that the internal power circuit of the board card has a fault. Professional electronic detection tools, such as a multimeter, etc., need to be used to detect key components in the power circuit, such as fuses, capacitors, voltage regulator chips, etc., and find and replace the damaged components. If the specific fault point cannot be determined, it is recommended to contact ABB's professional technical support personnel or maintenance service center for maintenance.

Communication fault

Fault phenomenon: The board card cannot communicate normally with other equipment, which may be manifested as the inability to receive or send control signals, data transmission errors or losses, etc., resulting in the entire control system malfunctioning or not operating as expected.

Solution: First, check whether the communication interface is well connected and ensure that the communication cable has no damage, open circuit, or short circuit, etc. Then, check whether the communication parameter settings are correct, including the communication protocol, baud rate, data bits, stop bits, etc., and ensure that they are consistent with the settings of other connected equipment. In the case of network communication, the network configuration and permission settings, etc., also need to be checked. If the above checks are all okay, it may be that the communication module of the board card has a fault, and professional personnel are required to detect and repair the communication module, or replace it with a new communication module.

Overheating fault

Fault phenomenon: The board card overheats after running for a long time, which may lead to a decline in performance, the appearance of error signals, or even damage to the board card.

Solution: Check whether the installation environment of the board card is well ventilated and whether there is sufficient space for heat dissipation. Avoid installing the board card in a narrow, enclosed, or high-temperature environment. Clean the dust on the surface of the board card and the cooling fan (if any), as dust accumulation may affect the heat dissipation effect. At the same time, check the load situation of the board card to see if there is an overloading operation. If so, the load needs to be adjusted or a board card with a higher power needs to be replaced.