Description

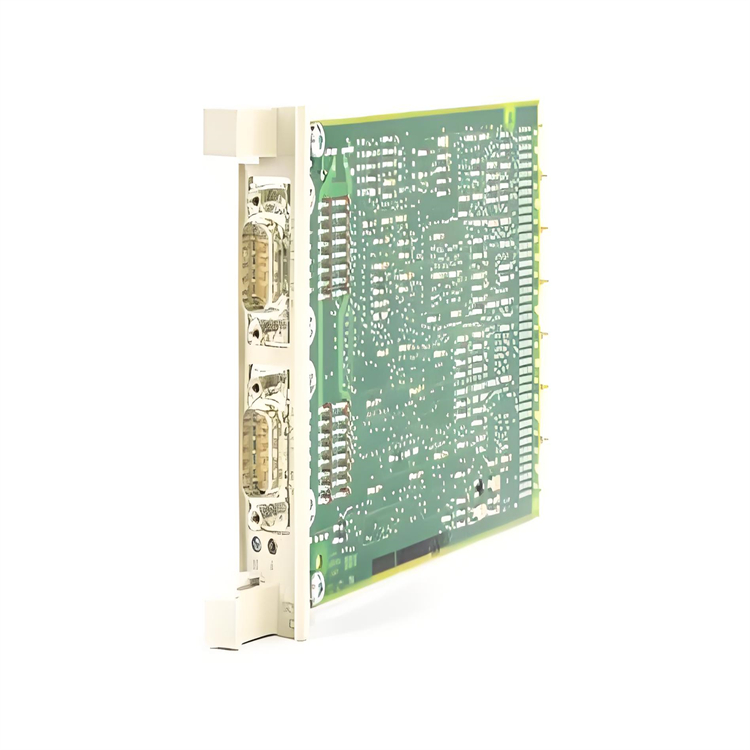

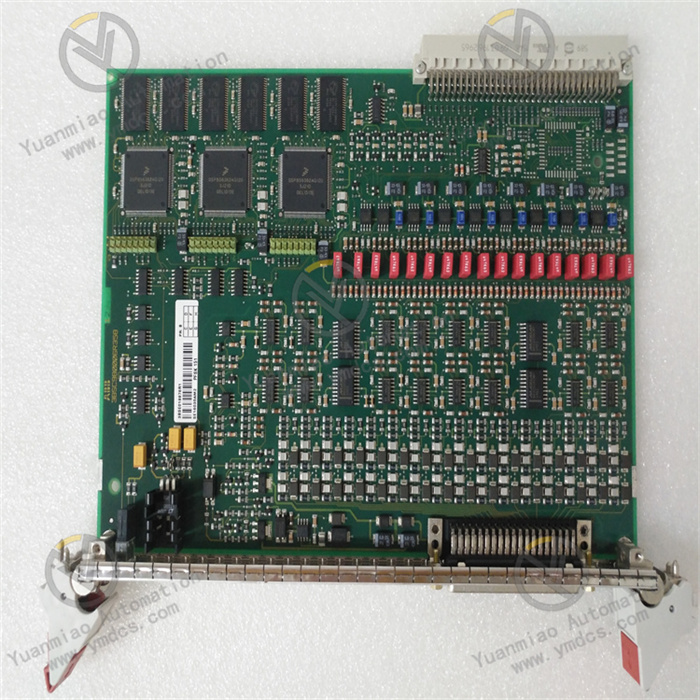

ABB PFSK162 3BSE015088R1

I. Overview

ABB PFSK162 3BSE015088R1 is a digital output module, positioned as a "digital signal execution and control unit for industrial field applications". Its core function is to receive digital commands from upper-level control systems such as PLC and DCS, convert them into stable relay output signals, and drive the operation of on-site actuators including motors, valves, solenoid valves and indicator lights. Meanwhile, it integrates functions such as signal isolation and overload protection, ensuring the accurate transmission of control commands and the safe operation of actuators in complex industrial environments. It is widely used in diverse industrial scenarios such as manufacturing production lines, chemical plants, energy stations and building automation systems.

II. Core Features

Highly Stable Relay Output and Load Adaptability: It supports 16 relay output channels, with each channel having a maximum carrying current of 2A (AC 250V/DC 30V) and a switch service life of over 1 million cycles, enabling flexible adaptation to inductive, resistive and capacitive loads. The built-in surge absorption circuit can effectively suppress instantaneous high voltage generated during load startup and shutdown, protecting relay contacts and extending the service life of the module.

Industrial-grade Anti-interference and Isolation Protection: It adopts photoelectric isolation technology, with an isolation voltage of up to 2500VAC between channels and between channels and power supply. This can effectively block interference from on-site electrical circuits, signal crosstalk and high-voltage surges, avoiding damage to the module's core circuits and distortion of control commands. Compliant with industrial-grade vibration resistance standards, it can withstand vibration impacts caused by the operation of on-site equipment, ensuring 24/7 continuous and stable operation.

Easy Integration and Efficient Operation & Maintenance: It supports the high-speed Profibus DP communication protocol with a maximum data transmission rate of 12Mbps, enabling real-time command interaction and status feedback with upper-level systems. The spring terminal wiring design allows tool-free and fast wiring, and when combined with standardized rail mounting, it greatly improves the efficiency of installation and commissioning. Each channel is equipped with an independent status indicator light, making the on/off status of actuators intuitively visible and facilitating quick troubleshooting.

Redundant Power Supply and Multiple Safety Protections: It supports 24VDC redundant power supply design. When one power supply path fails, the other path can switch seamlessly, ensuring uninterrupted operation of the module and preventing control interruptions from affecting the entire production process. Built-in functions including reverse power connection protection, overvoltage protection and overload protection can effectively respond to emergencies such as wiring errors, voltage anomalies and load overload, preventing damage to the module and downstream actuators.

- Modular Design and System Compatibility: It features an independent modular structure. When a single module fails, it can be disassembled and replaced individually without shutting down the entire system, greatly reducing operation and maintenance downtime losses. It is compatible with mainstream ABB control systems and various third-party PLC/DCS, supports user-defined output logic and fault alarm mechanisms, and is suitable for different application scenarios such as standalone machine control and multi-device linkage.

III. Technical Parameters

| Parameter Name | Specification |

|---|---|

| Product Model | ABB PFSK162 3BSE015088R1 |

| Product Type | Digital output module, relay output type, dedicated for industrial field control |

| Product Attributes | Modular design, photoelectric isolation, redundant power supply |

| Power Supply Parameters | Operating Voltage: 24VDC (redundant power supply); Rated Power Consumption: ≤6W |

| Output Parameters | Output Channels: 16 relay output channels; Maximum Single-channel Load: 2A (AC 250V/DC 30V); Switch Service Life: ≥1 million cycles; Isolation Voltage: 2500VAC (between channels / between channels and power supply) |

| Communication Method | Communication Protocol: Profibus DP; Transmission Rate: Up to 12Mbps; Interface Type: DB9 pin interface |

| Physical Parameters | Dimensions: 100mm×160mm×60mm; Net Weight: Approx. 220g; Mounting Method: 35mm standard DIN rail mounting |

| Environmental Adaptability | Operating Temperature: -20℃~60℃; Protection Rating: IP20; EMC Resistance (IEC 61000-4); Vibration Resistance (IEC 60068-2-6) |

| Compatibility & Adaptation | Compatible with ABB AC800M, S400 control systems and various PLC/DCS; Suitable for actuators such as motors, valves and indicator lights |

| Additional Information | Warranty Period: 12 months; Protection Functions: Reverse power connection protection, overvoltage protection, overload protection, surge absorption protection |

IV. Working Principle and Application Logic

The ABB PFSK162 3BSE015088R1 module realizes closed-loop control between upper-level systems and on-site actuators based on the core working logic of "command reception - signal isolation - output execution - status feedback". Its core working process is as follows:

After being connected to the 24VDC redundant power supply, the module completes self-diagnosis, confirms that the internal circuits, output channels and relay contacts are working normally, and enters the ready state. It receives digital control commands sent by PLC and DCS via the Profibus DP communication bus, and synchronously completes command decoding and validity verification.

The decoded control commands are transmitted to the output drive circuit through the photoelectric isolation module, achieving electrical isolation between the upper-level system and on-site actuators, and blocking external interference and high-voltage surges. The drive circuit triggers the action of the relay of the corresponding channel, closing or opening the actuator's power supply circuit to complete control actions such as startup-shutdown and switching.

The module monitors the status of each relay contact and the operating condition of loads in real time, and feeds back the execution results (on/off status) to the upper-level system via the communication bus, providing a basis for the optimization of control logic. Meanwhile, the built-in overload and surge detection circuits monitor changes in load current in real time, and trigger protection mechanisms in case of anomalies.