Description

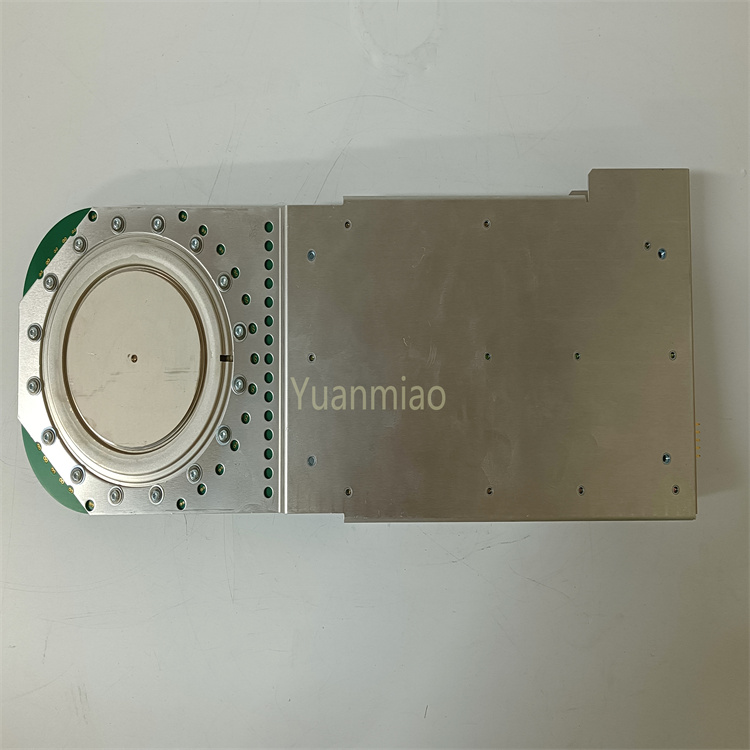

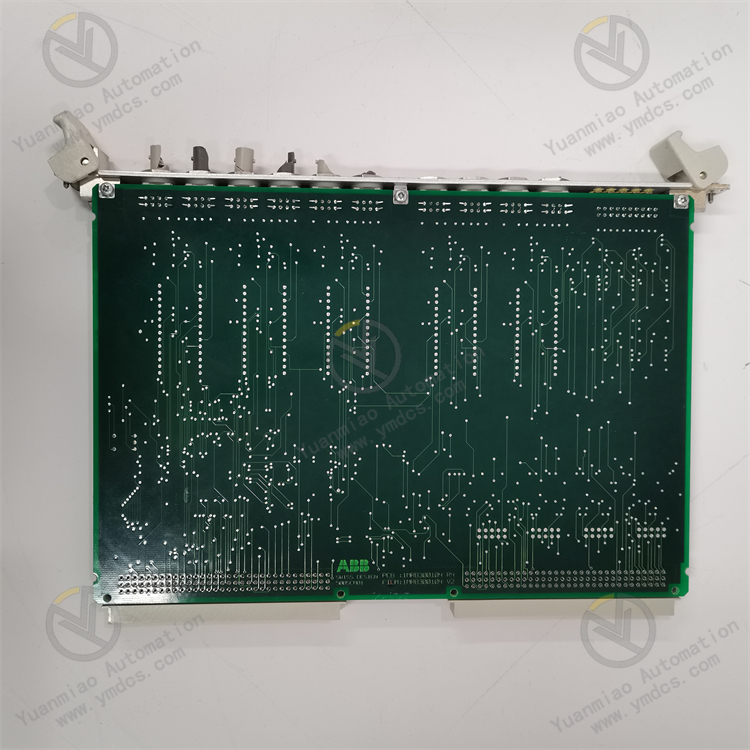

ABB 500SCM01 1MRB150004R0001 1MRB200059/C

The ABB 500SCM01 (Part Number: 1MRB150004R0001, Version: 1MRB200059-C) is a coupling module applied in the field of industrial automation.

Functional Features

- Efficient Data Transmission: Provides stable and low-latency data communication services to ensure the efficient operation of industrial systems, meeting the needs for fast and accurate data interaction between various automated devices.

- Modular Design: Compact in size, easy to integrate into existing industrial systems, and supports flexible expansion, enabling users to upgrade systems and expand functions according to actual requirements.

- High Reliability: Utilizes industrial-grade components with strong anti-interference capabilities, capable of stable operation in harsh industrial environments, including high temperatures, humidity, and electromagnetic interference.

Technical Parameters

- Weight: Approximately 370 grams, lightweight for easy installation and handling.

- Communication Capability: Supports Ethernet TCP/IP and serial (e.g., RS232/RS422/RS485) communication, providing extended communication functions for all rack monitoring values and statuses to integrate with process control and other automation systems. Supported protocols include the Modicon Modbus protocol (via serial communication), Modbus/TCP protocol (a variant of serial Modbus for TCP/IP Ethernet communication), and the proprietary Bently Nevada protocol (for communication with 3500 rack equipment and data acquisition packages).

- Other Features: Equipped with LED indicators to display the module's operating status and ongoing processing, facilitating monitoring and diagnosis by operators.

Application Areas

- Power Systems: Used in power monitoring and protection systems to ensure reliable communication between various devices in the power system, enabling real-time monitoring and control of power parameters to guarantee the safe and stable operation of the power system.

- Process Control: Serves as a data coupler in factory automation systems, enhancing signal processing capabilities to achieve precise control of various parameters in the production process, optimizing production workflows, and improving production efficiency and product quality.

- Automated Production Lines: Connects various devices on automated production lines, such as robots, sensors, and actuators, to enable collaborative operation and data sharing between devices, improving the automation level and production efficiency of the production line.

Common Faults, Possible Causes, and Solutions for the ABB 500SCM01 1MRB150004R0001 Module

I. Power-Related Faults

- Module Unpowered (Power Indicator Off)

- Possible Causes:

- Incorrect power connection or loose wiring.

- Power voltage outside the module's allowable range (e.g., too low, too high, or excessive fluctuations).

- Fuse blown or circuit breaker tripped in the power circuit.

- Internal power circuit damage in the module.

- Solutions:

- Check power wiring to ensure correct positive/negative connections (e.g., L+/M markings), and use a multimeter to measure input voltage within the rated range (e.g., 24V DC ±10%).

- Inspect front-end power equipment (e.g., switching power supplies) for normal operation, and replace blown fuses or reset circuit breakers.

- If voltage is normal but the module remains unresponsive, try power cycling; if ineffective, the module may have a hardware fault and require replacement by contacting ABB.

II. Communication Faults

- Unable to Communicate with Master Station/System (e.g., PROFIBUS, Ethernet)

- Possible Causes:

- Incorrect communication parameter settings (e.g., station address, baud rate, protocol type mismatch).

- Loose, short-circuited, or damaged communication cables (e.g., RS-485 bus without terminal resistors, poor Ethernet cable contact).

- Faulty master station equipment or damaged communication interface.

- Faulty communication chip or interface hardware in the module.

- Solutions:

- Confirm that the module's communication parameters (e.g., station address, baud rate) match the master station, and reset them via DIP switches or configuration software (refer to the manual).

- Inspect communication cable connections, test continuity with a multimeter, and ensure bus topology complies with specifications (e.g., terminal resistors activated only at both ends of the network segment).

- Test with a working module of the same type; if communication is restored, the original module's communication interface may be faulty and require repair or replacement.

- Use diagnostic tools (e.g., PROFIBUS analyzer, PING command) to check network signal quality and rule out interference from the master station or other slave devices.

III. Signal Input/Output (I/O) Faults

- Digital Input (DI) Unresponsive

- Possible Causes:

- Incorrectly applied input signal (e.g., insufficient voltage, faulty signal source).

- Loose, oxidized, or incorrectly wired input terminals (e.g., no common ground).

- Damaged or misconfigured module input channels (e.g., channel not enabled).

- Solutions:

- Measure input signal voltage (e.g., 24V DC signals require ≥15V for recognition) to ensure the signal source is normal.

- Replug terminal blocks, clean oxidized contacts, and check wiring against the module's terminal definition diagram.

- Confirm via configuration software that input channels are enabled, and try switching to another channel for testing; if all channels fail, the module may have hardware issues.

- Digital Output (DO) Unable to Drive Load

- Possible Causes:

- Output load current exceeds the module's rated value (e.g., single-channel maximum 0.5A), triggering overload protection.

- Incorrect output terminal wiring or load short circuit.

- Damaged or misconfigured module output channels (e.g., output value not written correctly).

- Solutions:

- Check load power; if exceeding the rated current, use external relays or contactors to expand capacity.

- Disconnect the load, measure resistance between output terminals with a multimeter to confirm short circuits, and reconnect after repairs.

- Force output via software (e.g., write 1 or 0xFF) and observe module indicator changes; if ineffective, the channel may be damaged.

IV. Abnormal Indicator Lights

- Fault Indicators (e.g., ERR, BF Lights On/Flashing)

- Possible Causes:

- Internal module errors (e.g., firmware faults, hardware self-test failures).

- Communication bus faults (e.g., PROFIBUS bus error indicated by BF light).

- Exceeded environmental parameters (e.g., high temperature, voltage fluctuations).

- Solutions:

- Refer to the LED indicator definitions in the module manual to identify fault types (e.g., BF light indicates bus fault, requiring communication connection checks).

- Power cycle the module; if indicators remain abnormal, attempt factory reset or firmware update (follow official guidelines).

- Check environmental temperature and humidity within allowable ranges (e.g., -25°C~+60°C) and ensure good heat dissipation.

Other Brand-Related Products

BENTLY 3500/64M 140734-05 Dynamic Pressure Module

WOODWARD 8402-319 8402-119 Synchronizer Governor/Ccontrol Unit

Schneider Electric 140CPU67160C CPU Processor

REXROTH VT-HNC100-1-22/W-08-C-0 | Digital Axis Controllers

Motorola MVME162P-344 | Embedded Controller