Description

ABB PM633 3BSE008062R1

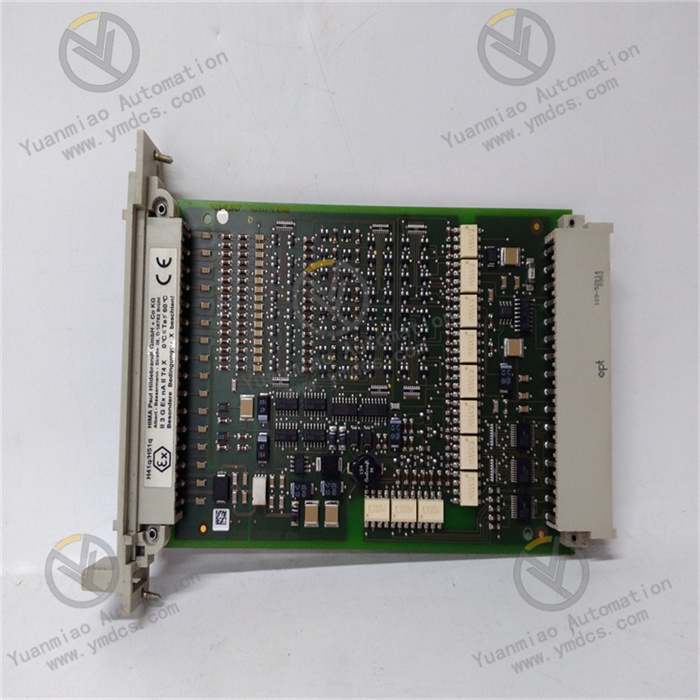

The ABB PM633 3BSE008062R1 is the main processor unit in the ABB 800xA system.

Hardware Parameters

- Dimensions and Weight:

Net depth/length: 310.5mm, net height: 38.7mm, net width: 238.5mm, net weight: 1.445kg. - Processor:

Based on the MC68340/25MHz processor, it provides stable computing power and response speed, capable of handling complex control and data processing tasks. - Memory:

Typically equipped with a certain capacity of RAM (specific capacity not explicitly stated), and also features a CompactFlash interface for storage expansion. - Communication Interfaces:

Equipped with multiple communication interfaces, including Ethernet, serial communication, and fieldbus interfaces, enabling easy connectivity and communication with other devices, systems, and networks. The COM3 port on its CPU board is an RS-232C port with modem control signals, while COM4 is isolated for connecting configuration tools. - Others:

Fitted with a backup battery (4943013-3) to ensure data security and normal system operation during power outages.

Functional Features

- Powerful Processing Capability:

Supports multitasking and parallel operations, capable of handling multiple control tasks and data processing requirements simultaneously, enhancing overall system efficiency and flexibility. - High Availability:

Supports CPU redundancy. By cooperating with another processor unit, it achieves redundant backup functionality. When the main processor fails, the standby processor can quickly take over operations, ensuring continuous and stable system operation, reducing downtime, and improving system reliability and availability. - High Reliability:

With EMC certification, it demonstrates good electromagnetic compatibility, stable operation in complex electromagnetic environments, strong anti-interference capability, and adaptability to various industrial field environments.

Application Fields

As a high-performance and high-reliability processor module, it is widely used in various industrial automation control systems, such as chemical, power, metallurgy, pharmaceutical, food and beverage industries. In these industries, it is used for precise control of production processes, data acquisition and processing, equipment monitoring and management, etc., to achieve automation, optimization, and intelligence of production processes.

Common Faults and General Solutions

1. Power-Related Faults

- 1.1 No Power Supply to Module (Power Indicator Off)

- Possible Causes:

- Faults in the power input circuit (e.g., loose connections, open circuits).

- Damaged power adapter or abnormal voltage output (e.g., 24VDC power supply not meeting standards).

- Faults in the module's internal power circuit (e.g., blown fuse, damaged capacitor).

- Solutions:

- Check power input wiring and use a multimeter to measure whether the power voltage meets the module's requirements (e.g., 24VDC ±10%).

- Replace the power adapter with one of the same specifications to eliminate external power issues.

- If there is an internal circuit fault, contact ABB official maintenance or replace the module.

- 1.2 Abnormal Power Indicator (Flashing or Discolored)

- Possible Causes:

- Unstable power voltage or excessive ripple.

- Overload or short circuit in the module's internal power supply.

- Solutions:

- Improve power quality using voltage stabilizers or filtering devices.

- Disconnect the module's external loads and gradually troubleshoot whether external device short circuits cause the overload.

2. Communication-Related Faults

- 2.1 Failure to Communicate with Host Computer or Other Devices

- Possible Causes:

- Incorrect communication parameter settings (e.g., mismatched baud rate, parity, IP address).

- Damaged communication cables, poor contact, or incorrect wiring (e.g., reversed RS-485 positive and negative poles).

- Hardware faults in communication ports (e.g., damaged chips).

- Incompatible communication protocols or uninstalled software drivers.

- Solutions:

- Verify the parameter settings of the module and communication devices (refer to the manual) to ensure consistency.

- Replace communication cables and check whether the wiring meets standards (e.g., RS-485 requires termination resistors).

- Use a serial debugging tool (e.g., Serial Assistant) to test whether the port sends and receives data normally.

- Update or reinstall communication drivers and confirm protocol compatibility (e.g., Modbus, Profinet, etc.).

- 2.2 Communication Interruptions or Data Loss

- Possible Causes:

- Electromagnetic interference (e.g., high-power equipment near communication lines).

- Excessive communication distance or cable specifications not meeting requirements (e.g., unshielded twisted-pair cables not used).

- Buffer overflow in the module or communication device (excessive data transmission rate).

- Solutions:

- Isolate communication cables from high-power lines, use shielded cables, and ensure reliable grounding.

- Shorten the communication distance or add repeaters to ensure cable impedance matching.

- Reduce the communication rate or optimize data transmission logic to avoid sudden high-data-volume traffic.

3. Program Operation and Storage Faults

- 3.1 Program Cannot Be Downloaded or Run

- Possible Causes:

- Incompatibility between the programming software version and the module's firmware.

- Damaged or improperly inserted storage media (e.g., flash cards).

- Program logic errors causing infinite loops or memory overflow.

- Solutions:

- Upgrade the programming software or module firmware to compatible versions (refer to ABB official documentation).

- Reinsert or replace the flash card, and try re-downloading the program after formatting.

- Use debugging tools to check the program logic line by line and release redundant memory.

- 3.2 Data Loss or Storage Anomalies

- Possible Causes:

- Poor contact or physical damage to the flash card.

- Power outages or strong interference during data writing.

- Solutions:

- Check the flash card slot to ensure good contact; regularly back up important data.

- Equip the module with an Uninterruptible Power Supply (UPS) to avoid sudden power outages.

4. Environmental and Hardware Faults

- 4.1 Module Overheating or Abnormal Temperature

- Possible Causes:

- Poor ventilation in the installation environment, with cooling holes blocked by dust.

- Operating temperature exceeding the module's rated range (e.g., above 60°C).

- Faulty internal fan or detached heat sink.

- Solutions:

- Clean the module's cooling holes to ensure good ventilation at the installation location.

- Improve the environmental temperature (e.g., add air conditioning, fans) and avoid direct sunlight.

- Check the internal fan's operation and replace heat dissipation components if necessary.

- 4.2 Hardware Damage (e.g., Abnormal Indicators, Damaged Interfaces)

- Possible Causes:

- Mechanical vibrations causing loose internal components or solder joint detachment.

- Circuit corrosion or short circuits due to environmental factors such as humidity and dust.

- Port chip damage from lightning strikes or surge voltages.

- Solutions:

- Check whether the module is firmly installed and reinforce terminal connections and internal components.

- Improve the installation environment and take dust-proof and moisture-proof measures (e.g., use sealed cabinets).

- Install surge protectors to avoid high-power surges; if hardware is damaged, return it to the factory for repair or replace the module.

5. Other Common Issues

- 5.1 Abnormal Output Signals (e.g., Relays Not Activating, Unstable Analog Outputs)

- Possible Causes:

- Open output circuits or faulty loads.

- Incorrect analog output parameter settings (e.g., mismatched range).

- Damaged module output channels.

- Solutions:

- Check output wiring and load status, and use a multimeter to measure output voltage/current.

- Reconfigure output parameters and calibrate analog channels (if required).

- Replace backup output channels or modules.

- 5.2 No Response to Input Signals

- Possible Causes:

- Faulty input sources (e.g., damaged sensors, open switches).

- Incorrect input mode settings (e.g., mismatched DC/AC type, voltage level).

- Solutions:

- Test whether the input source signal is normal and replace faulty sensors or switches.

- Confirm that the module's input type matches the signal (e.g., DC 24V input requires corresponding voltage levels).