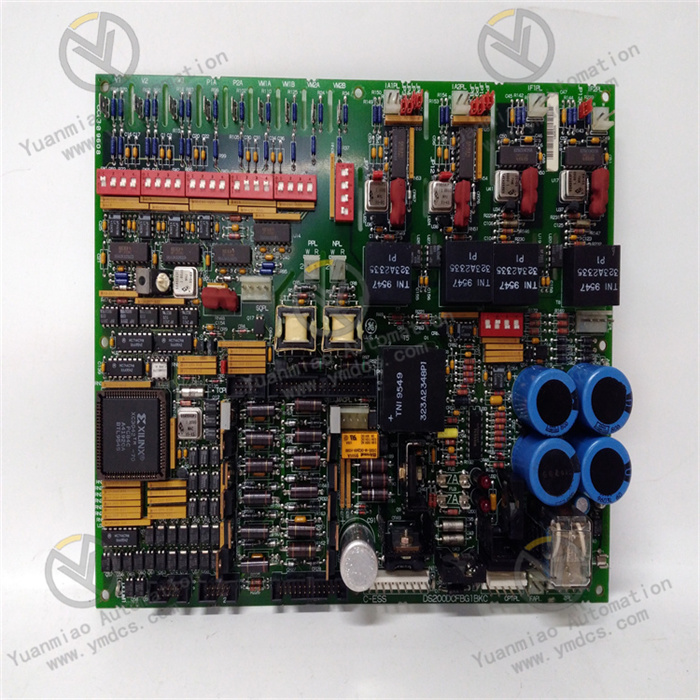

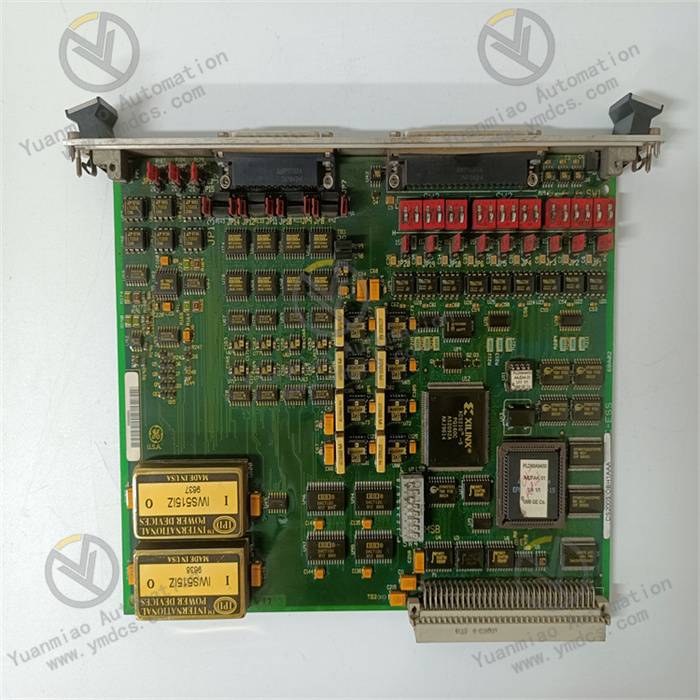

Description

Functional Features 1. Precise Control Function: It can precisely adjust key parameters in industrial processes, such as speed, pressure, temperature, etc., to meet the requirements for control accuracy in the production process. For example, in the engine control system, it can accurately control the fuel injection quantity to ensure the stable operation of the engine. 2. Communication Capability: It supports multiple communication protocols, such as Modbus, Ethernet, etc., making it convenient to transmit data and communicate with other devices (such as PLC, host computer, etc.) to achieve system integration and remote monitoring. It can upload the operation status data of the device in real time and receive control instructions to remotely operate the device. 3. Fault Diagnosis and Protection: It has a complete fault diagnosis function, which can monitor the operation status of the device in real time, detect faults in a timely manner and issue alarms. At the same time, it also has protection functions such as overcurrent, overvoltage, and undervoltage, which can effectively protect the device from damage. 4. Data Processing Capacity: It has a powerful data processing capacity, which can quickly process and analyze the collected data to provide accurate data support for control decisions. For example, it can analyze a large amount of data transmitted by sensors in real time to optimize the control strategy. 5. Flexible Configuration: It can be flexibly configured according to different application requirements, such as setting control parameters, communication parameters, etc. Users can adjust the working mode and parameters of the device according to the actual production situation to adapt to different working scenarios.

Technical Parameters 1. Power Supply Voltage: It is usually powered by 24V DC to ensure the stable operation of the device. It may also support a certain range of voltage input, such as 18 - 30V DC. 2. Input and Output Channels: It has multiple analog input and output channels and digital input and output channels. For example, it may have 8 analog input channels, 4 analog output channels, 16 digital input and output channels, etc., and the specific number of channels may vary depending on the model. 3. Measurement Accuracy: The analog input accuracy can reach ±0.1% FS (full scale), which can accurately measure the changes of input signals to ensure the accuracy of control. 4. Communication Rate: The Ethernet communication rate can reach 10/100Mbps, and the serial communication rate can be between 9600bps and 115200bps to meet different communication requirements. 5. Operating Temperature Range: The general operating temperature range is from -40°C to 70°C, which can adapt to different industrial environment temperatures and ensure the normal operation of the device in harsh environments. Application Areas 1. Power Industry: In power generation equipment, such as gas turbines, steam turbines, etc., it can precisely control and monitor the operating parameters of the equipment to ensure the stable power supply of the power system. It can adjust the speed and output power of the generator to achieve a stable connection with the power grid. 2. Oil and Gas: It is used for the control of oil and gas extraction, transportation and processing equipment, such as compressors, pumps, etc. It can precisely control the operating status of the equipment according to the process requirements to improve production efficiency and safety. 3. Industrial Automation Production Lines: In the automation production lines of industries such as automotive manufacturing and electronic manufacturing, it can precisely control the production equipment to achieve the automation and intelligence of the production process and improve production efficiency and product quality. 4. Shipbuilding Industry: It is applied to the control and monitoring of ship engines to ensure the stable operation of the engines and improve the navigation performance and safety of the ship. It can adjust the working parameters of the engine in real time according to the operating status of the ship.

Common Faults and Solutions

1. Communication Faults

Reasons: Damaged communication cables, loose communication interfaces, incorrect communication parameter settings, etc.

Solutions: Check whether the communication cables are properly connected and if there is any damage, and replace the cables if there are problems; check whether the communication interfaces are loose and re-plug them; confirm whether the communication parameter settings, such as baud rate, data bits, stop bits, etc., are correct, and re-set the correct parameters.

2. Abnormal Control Accuracy

Reasons: Sensor failures, actuator failures, unreasonable control algorithm parameter settings, etc.

Solutions: Check whether the sensors are working properly and replace the faulty sensors; check whether the actuators are operating normally and repair or replace them if there are problems; adjust the control algorithm parameters, such as PID parameters, to improve the control accuracy.

3. Power Supply Faults

Reasons: Damaged power supply modules, abnormal power input, etc.

Solutions: Check whether the power supply modules have phenomena such as overheating and damage, and replace the faulty power supply modules; check whether the power input voltage is within the allowable range of the device to ensure normal power input.

4. Fault Alarms

Reasons: Faults of internal components of the device, interference of external signals, etc.

Solutions: Use professional detection equipment to detect the device, find and replace the faulty components; take electromagnetic shielding measures to reduce the interference of external signals; upgrade the software of the device to fix possible software faults.