Description

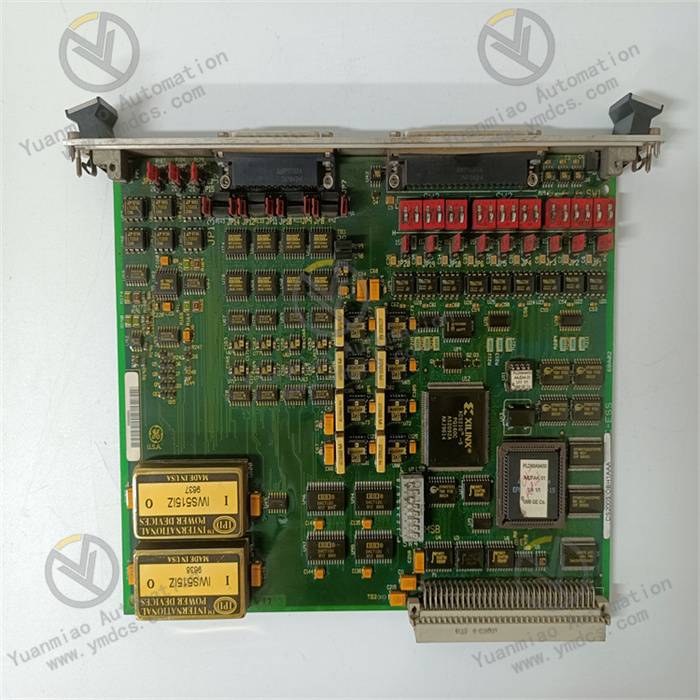

As part of the Mark V series control system, the DS200SIOBH1AAA is mainly responsible for collecting various signals from field devices, such as analog signals from sensors like temperature, pressure, and flow rate, as well as digital signals such as switch status and pulse signals. For analog signals, they are converted into digital signals through an analog-to-digital conversion circuit for processing and analysis by the control system; for digital signals, logical processing and transmission are carried out directly. At the same time, it also outputs control instructions from the control system to external actuators, such as motors and valves, to achieve the control of industrial processes and serves as a bridge for data interaction between the system and external devices. Fault Diagnosis and Alarm Self-diagnosis: The module has a self-diagnosis function and can monitor its own working status in real time, including periodic detection of key components such as the internal power supply, processor, memory, and communication interface. For example, it checks whether the power supply voltage is normal, monitors whether there are errors in the operation of the processor, detects whether the read-write function of the memory is normal, and checks whether the connection of the communication interface and signal transmission are in good condition. Once it detects its own fault, it will immediately send out a fault signal. Based on LED indication: The board is equipped with LED indicator lights, which can indicate the processing situation performed by the board. Through different states of the LED, such as on/off and flashing frequency, the operating status of the circuit board can be preliminarily judged, providing the first-step reference for fault diagnosis. With the help of troubleshooting tools: The troubleshooting tool on the driver can be started using the control panel. This tool is menu-driven, and users can select and scroll through buttons. It will test all components in the driver and provide a diagnostic report to help determine the location of the error.

Technical Parameters I/O points: It has multiple digital input/output points and analog input/output points. For specific quantities, refer to the product manual. Signal types: It supports various signal types, including digital signals (such as switching quantities and pulse quantities) and analog signals (such as voltage and current signals). Communication interface: It supports multiple communication protocols, such as Modbus and Profibus, for interconnection and data transmission with other devices. Operating temperature: It can operate stably within a certain temperature range, for example, from -40°C to 85°C. The actual range depends on the product specifications. Functional Features: High reliability: By using high-quality electronic components and advanced manufacturing processes, it can operate stably in harsh industrial environments, has strong anti-interference ability, can effectively reduce faults caused by factors such as electromagnetic interference, temperature changes, and humidity, and ensure the continuous and stable operation of the system. Multiple input and output functions: It usually has a rich variety of input and output interfaces, can receive various types of signal inputs, such as analog quantity inputs (such as voltage and current signals) and digital quantity inputs (switching signals), and can also provide corresponding analog quantity outputs and digital quantity outputs to meet the control requirements of different industrial devices and systems, and achieve precise control and monitoring of various industrial processes. Communication capability: It supports multiple communication protocols, can carry out efficient data interaction and communication with other devices or systems, for example, connect with the upper computer control system, other intelligent modules, or fieldbus devices to achieve information sharing and collaborative work in the distributed control system, and facilitate the centralized monitoring and management of the entire industrial system. Flexible configuration options: Users can flexibly configure the module through software or hardware settings according to specific application scenarios and control requirements, such as setting the range, accuracy, and filtering parameters of input and output signals, as well as selecting different communication modes and protocols, so that it can better adapt to various complex industrial control tasks. Diagnosis and self-protection functions: It has a complete set of diagnostic circuits and programs built-in, can monitor its own working status in real time. Once a fault is detected, it can quickly send out an alarm signal and take corresponding self-protection measures, such as automatically cutting off the output and entering the safety mode, etc., to prevent the fault from expanding further. At the same time, it also facilitates maintenance personnel to quickly locate and troubleshoot faults, improving the maintainability of the system.

Common Faults and Corresponding Solutions: Communication Fault Fault phenomenon: The module cannot communicate normally with the control system, resulting in the inability to transmit or receive data, and a module communication error code is displayed in the control system. Solution: First, check whether the communication cable is firmly connected and whether there are any damages or open circuits. If there are problems, replace the cable. Then confirm whether the communication parameter settings of the module match those of the control system, including the baud rate, data bits, stop bits, parity, etc. If there are errors, re-set them. In addition, you can try to power off and restart the module. Sometimes, the communication fault may be caused by a temporary software error, and it can be restored to normal after restarting. Abnormal Input Signal Fault phenomenon: The input signal received by the module does not match the actual value, or the input signal is unstable, with fluctuations, jumps, etc., affecting the accurate judgment of the field status by the control system. Solution: Check whether the input signal source is working properly, such as whether devices like sensors and switches are outputting correct signals. Tools such as a multimeter can be used to measure parameters such as the voltage and current of the input signal and compare them with the specification requirements of the module. If the signal source is normal, check whether the input channel of the module is damaged. You can try to connect the signal to other idle input channels to observe whether the signal can be received normally. If it is determined that the input channel is damaged, contact professional maintenance personnel or replace the module.

Output Signal Fault Fault phenomenon: The module cannot output the correct control signal, or the parameters such as the amplitude and frequency of the output signal do not meet the requirements, resulting in the connected actuator not working properly. Solution: Check whether the output setting parameters of the module are correct, and adjust the type, range, and other parameters of the output signal according to actual needs. Confirm whether the output load is within the rated load range of the module to avoid output faults caused by overload. If the load is normal, use instruments such as an oscilloscope to measure the output signal of the module and check whether the waveform, amplitude, etc. of the signal are normal. If the output signal is abnormal, there may be a problem with the output circuit inside the module, and professional maintenance or module replacement is required. Power Supply Fault Fault phenomenon: The module cannot work normally, the indicator light does not light up, or there are unstable phenomena such as frequent restarts and freezes, and there may be abnormal noises or odors from the power supply module. Solution: Check whether the external power supply is normal and measure whether the input power supply voltage is within the rated operating voltage range of the module. If the power supply voltage is too low or too high, adjust the power supply output or check the power supply line. If the power supply voltage is normal, check whether the power interface of the module is loose or in poor contact. If there are problems, re-plug or repair the interface. If all the above checks are normal, there may be a fault in the power circuit inside the module, and the module needs to be repaired or replaced. Module Overheating Fault phenomenon: The surface temperature of the module is too high, exceeding the normal operating temperature range, and the overheat protection mechanism may be triggered, resulting in a decline in module performance or stopping of work. Solution: Check whether the installation environment of the module is well ventilated and whether there are other heat-generating devices around that affect heat dissipation. Ensure that the module is installed in a cabinet that meets the requirements and has enough heat dissipation space. Clean the surface of the module and the surrounding area of dust and debris, as dust accumulation may affect the heat dissipation effect. If the module operates under high load for a long time, consider whether the system configuration can be optimized to reduce the working burden of the module. If the above measures cannot solve the problem, there may be a fault in the heat dissipation device or circuit inside the module, and professional personnel are required for maintenance.