Description

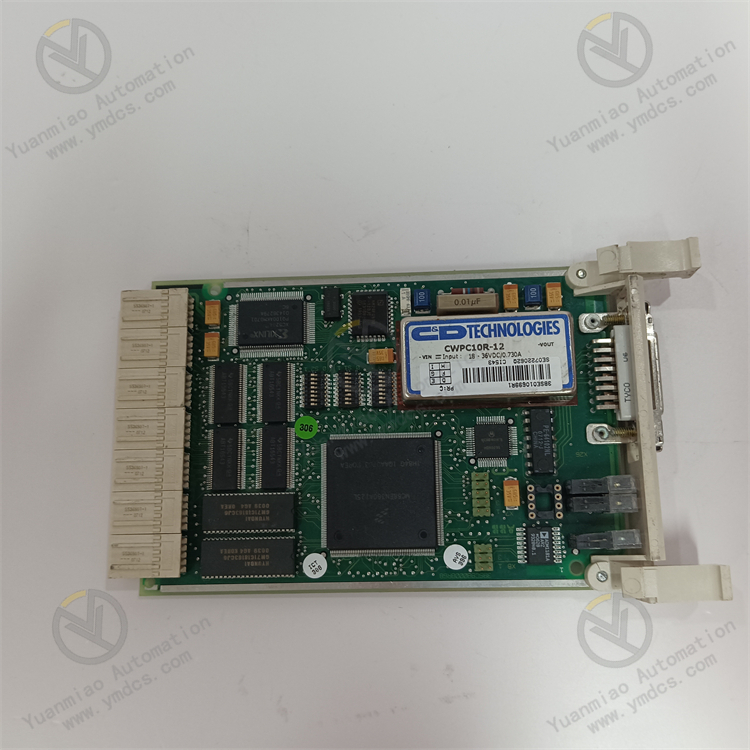

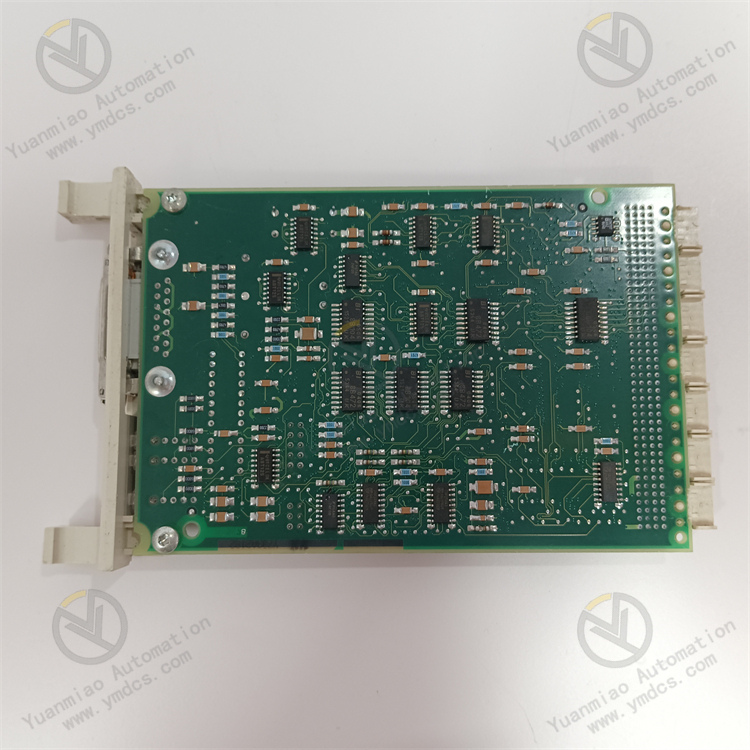

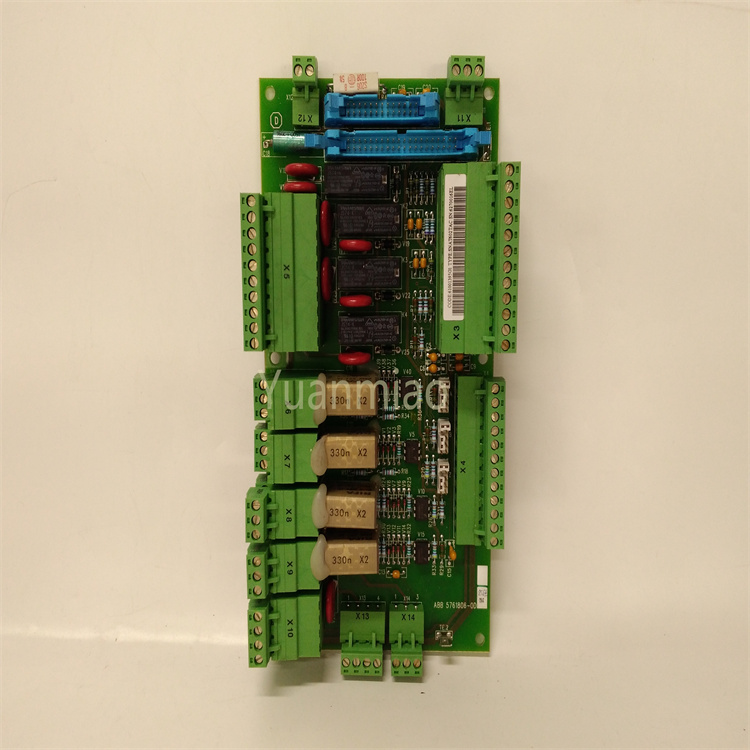

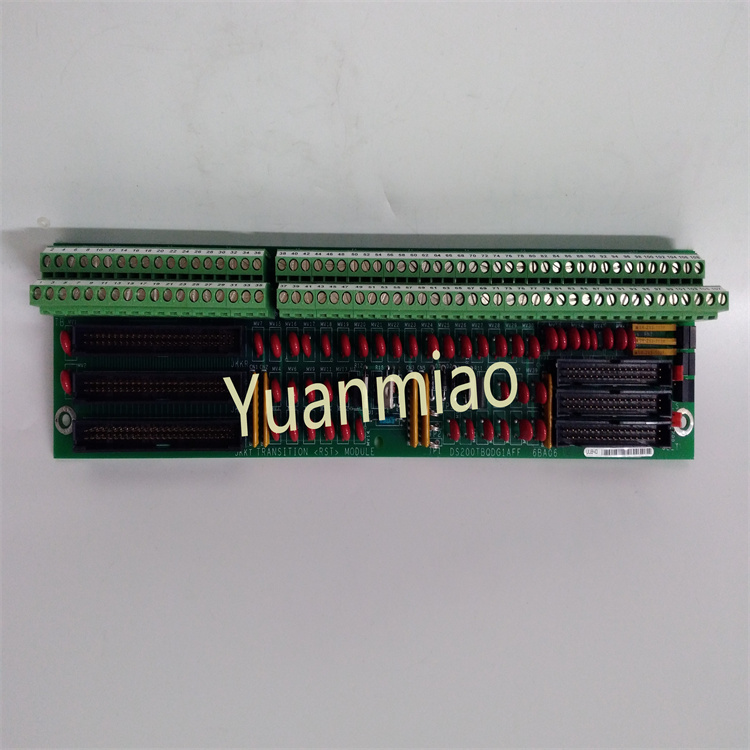

ABB CI543 3BSE010699R1 Communication Interface

I. Product Positioning and Application Scenarios

Positioning:

As a communication interface module for ABB AC 800M series controllers, it serves as a key component in industrial automation systems to enable communication between controllers and field devices, subsystems, or host computers. Supporting multiple communication protocols, it offers high reliability and anti-interference capabilities, suitable for real-time data interaction and system integration in complex industrial environments.

As a communication interface module for ABB AC 800M series controllers, it serves as a key component in industrial automation systems to enable communication between controllers and field devices, subsystems, or host computers. Supporting multiple communication protocols, it offers high reliability and anti-interference capabilities, suitable for real-time data interaction and system integration in complex industrial environments.

Application Scenarios:

- Process Automation:

- Distributed Control Systems (DCS) in industries such as chemical, petroleum, metallurgy, and power.

- Connecting devices like PLCs, sensors, actuators, and smart instruments to achieve data acquisition and command issuance.

- Machine Automation:

- Networking production line equipment (e.g., packaging machinery, conveyor systems), supporting collaboration with robots and vision systems.

- Energy Management Systems (EMS):

- Integrating photovoltaic inverters, energy storage devices, and power grid monitoring equipment to enable real-time energy data monitoring and optimized control.

- Building Automation:

- Connecting HVAC, fire protection, and security systems to build intelligent building management systems (BMS).

II. Key Functions and Technical Characteristics

Communication Protocol Support

- Mainstream Industrial Protocols:

- PROFIBUS DP/V1 (master/slave mode)

- Modbus RTU/ASCII (serial communication)

- CANopen (industrial fieldbus)

- Extended Functions:

- Supports custom protocol development (via ABB programming tools).

- Can be configured as a gateway to enable interconnection between devices with different protocols (e.g., PROFIBUS to Modbus).

Electrical and Mechanical Characteristics

- Interface Types:

- 2× DB9 serial ports (RS-232/RS-485 optional)

- 1× PROFIBUS-specific interface (9-pin Sub-D connector)

- Electrical Parameters:

- PROFIBUS: Up to 12 Mbps

- Modbus: Up to 115.2 kbps

- Power supply: 24 V DC (±10%)

- Power consumption: ≤5 W

- Communication speeds:

- Mechanical Specifications:

- Dimensions: Approximately 100 mm × 150 mm × 50 mm (W×H×D)

- Mounting: Rail mounting (compatible with DIN 35 mm standard)

Reliability and Safety

- Anti-Interference Design:

- Complies with IEC 61000-4 EMC standards, adapting to strong electromagnetic environments.

- Isolation protection: Electrical isolation between communication interfaces and internal controller circuits (isolation voltage ≥500 V AC).

- Diagnostic Functions:

- Built-in LED status indicators (power, communication link, fault) for real-time module status monitoring.

- Supports online fault diagnosis (e.g., communication timeout, parity error) and remote monitoring via ABB Control Builder M software.

III. Technical Parameters Table

| Parameter | Value/Description |

|---|---|

| Model | CI543 3BSE010699R1 |

| Series | AC 800M |

| Communication Protocols | PROFIBUS DP, Modbus, CANopen, etc. |

| Number of Interfaces | 2× Serial ports (RS-232/485) + 1× PROFIBUS |

| Power Supply Voltage | 24 V DC (±10%) |

| Power Consumption | ≤5 W |

| Communication Speed (PROFIBUS) | 9.6 kbps ~ 12 Mbps (adaptive) |

| Operating Temperature | -20°C ~ +60°C (no condensation) |

| Protection Class | IP20 (requires installation in control cabinets) |

IV. Supporting Products and Alternatives

Ecosystem

- Controllers: ABB AC 800M series (e.g., PM866, PM886).

- Human-Machine Interfaces (HMI): ABB Panel 800, Pro-face GP series.

- Engineering Software: ABB Freelance, ABB Ability™ System 800xA.

Alternative Models

- In-Brand Upgrade: CI546 (supports Ethernet communication, e.g., PROFINET, EtherNet/IP).

- Cross-Brand Compatibility:

- Siemens CP 342-5 (PROFIBUS module)

- Rockwell 1769-SDN (DeviceNet gateway)

Note: When replacing, ensure protocol compatibility, electrical interface matching, and software configuration tool compatibility.

V. Typical Application Cases

- Chemical Reactor Control:

Connects PROFIBUS slaves (e.g., pressure transmitters, temperature controllers) via CI543 to collect real-time reactor data and transmit it to the AC 800M controller, enabling automatic adjustment of valve openings and stirring speed. - Intelligent Warehousing System:

Uses Modbus protocol to connect stacker cranes, barcode scanners, etc. The module acts as a communication hub to upload data to the MES system, optimizing inventory management and logistics scheduling.

Installation and Configuration of ABB CI543 3BSE010699R1 Module

Installation Steps

- Pre-Installation Preparation:

- Inspect Equipment: Verify that the module and its accessories are intact. Contact the supplier immediately if damage or shortages are found.

- Read Instructions: Carefully review the module’s installation manual to familiarize yourself with its performance characteristics, installation requirements, and safety precautions.

- Determine Installation Location: Choose a dry, ventilated, dust-free, and corrosion-free indoor environment, away from direct sunlight, high temperatures, and strong magnetic interference sources.

- Prepare Tools: Ready common installation tools such as screwdrivers and wrenches.

- Module Fixing:

Place the CI543 module steadily in the selected installation location and secure it to the control cabinet’s mounting plate or suitable support structure using screws to ensure firm installation without shaking. - Power Connection:

Select an appropriate power cable based on the module’s rated voltage (typically 24VDC). Connect the positive and negative poles of the power supply to the corresponding terminals of the module, ensuring correct polarity. - Communication Cable Connection:

Connect the CI543 module’s communication interface to other devices (e.g., controllers, host computers) using suitable communication cables (e.g., Ethernet cables) according to the actual application scenario and connected devices. Ensure secure cable connections and compliance with relevant cabling specifications, avoiding parallel routing with high-voltage lines to reduce electromagnetic interference. - Grounding:

To ensure equipment safety and stable operation, connect the module’s grounding terminal to a reliable grounding system via a dedicated grounding wire. The grounding resistance should meet relevant standards, generally not exceeding 4 ohms.

Configuration Methods

- Using Automation Builder Software:

Typically, ABB’s Automation Builder software is required to configure the CI543 module. Ensure the software is correctly installed on the configuration computer and establishes a communication connection with the control system where the module is located. - Adding the Module to the Device Tree:

Open the Automation Builder software and locate the node corresponding to the module’s installation position (e.g., "Slot 1" or "Slot 2" of the "Expansion Bus") in the software’s device tree. Right-click the node, select "Add Object," and choose the "CM5XX Master Module" corresponding to the CI543 module from the pop-up window. Then right-click the added "CM5XX Master Module," select "Add Object," and find the CI543 device to add it to the device tree. - Adding Related I/O Modules (if applicable):

If there are S500 I/O modules used with the CI543 module in the system, right-click the CI543 device, select "Add Object," and choose the corresponding I/O module from the list to add it. - Parameter Configuration:

Double-click the CI543 module in the device tree to open the parameter editing window. In the "CI5XX_IO Parameters" tab, configure various module parameters, such as communication protocols (e.g., Ethernet/IP, Profinet), IP address, subnet mask, gateway, and other application-specific parameters. Set these parameters accurately according to the actual network environment and application requirements. After configuration, save the settings and download them to the module to take effect.