Description

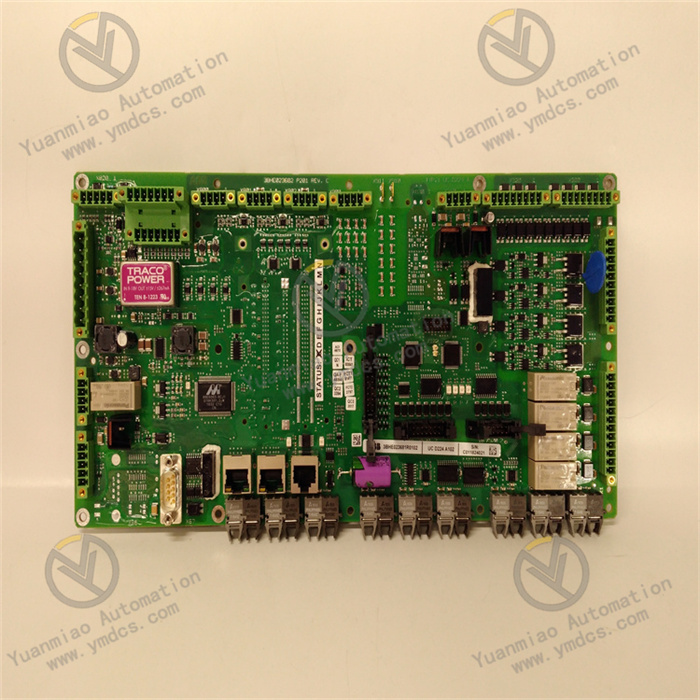

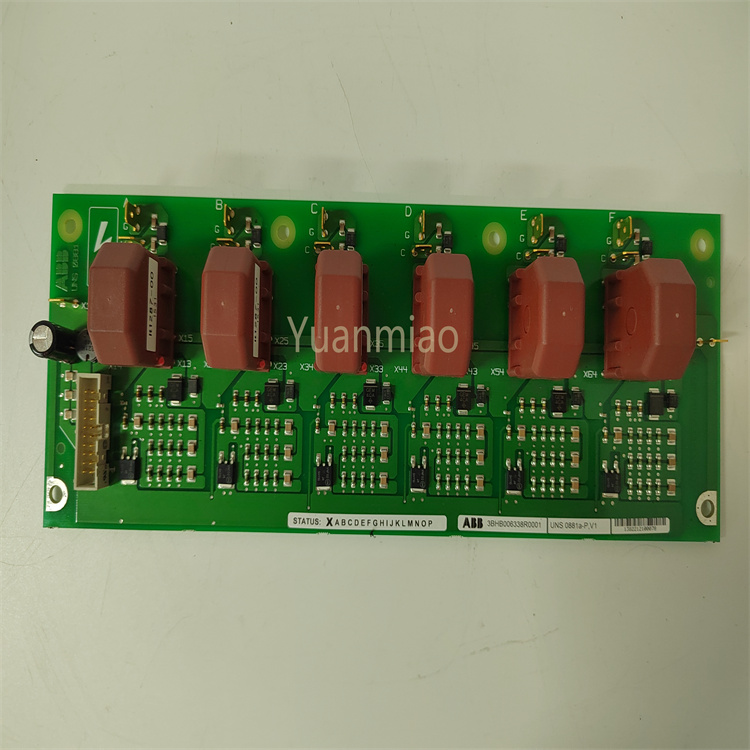

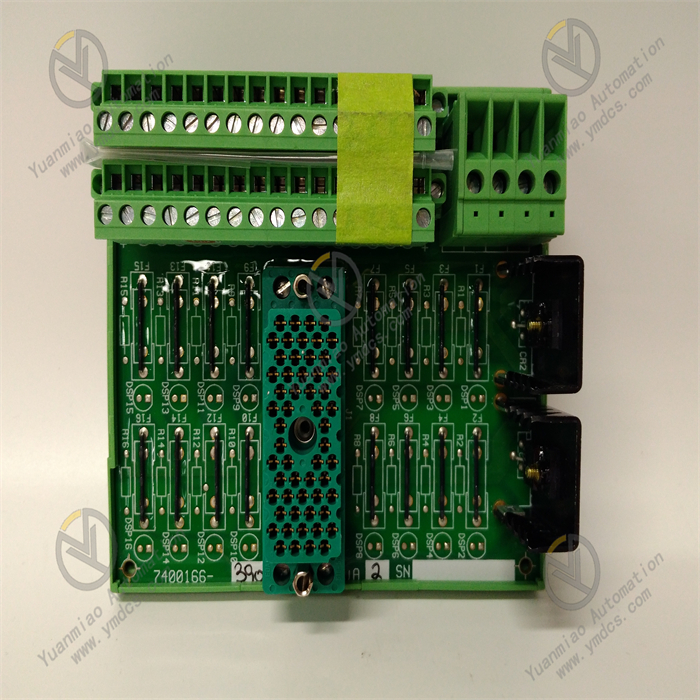

ABB PPD117A3011 3BHE030410R3011

ABB PPD117A3011 3BHE030410R3011 is an excitation controller module manufactured by ABB, widely used in power systems, generator sets, industrial process control and other fields.

Main Features

- Precise Voltage Regulation: Controls the output voltage of the generator by adjusting the excitation current to ensure stable operation of the power system.

- Real-time Feedback Control: Monitors the generator's operating status in real time and automatically adjusts the excitation current based on feedback signals to maintain voltage within the set range.

- High Reliability: Designed for industrial environments with high reliability requirements, capable of adapting to extreme operating conditions such as temperature changes and current fluctuations.

- Multiple Protection Functions: Built-in protection functions such as overvoltage, overcurrent, and undervoltage to improve equipment safety and prevent failures.

- Flexible Configuration: Supports multiple communication protocols and interfaces, enabling easy integration with other automation devices or control systems to meet different control needs.

- Modern Control Technology: Incorporates digital control technology to provide higher precision and faster response speed.

Technical Parameters

1. Input Characteristics

- Rated Input Voltage: Typically AC 220V or AC 380V; some modules may also support DC inputs such as DC 24V or DC 48V.

- Input Voltage Range: Generally tolerates certain voltage fluctuations, e.g., ±10%–±15% for AC inputs and ±5%–±10% for DC inputs. For example, if the rated input is AC 220V, the input voltage range may be AC 198V–242V.

- Input Frequency: For AC inputs, it usually supports industrial standard frequencies of 50Hz or 60Hz, with allowable frequency deviations (e.g., ±5%).

2. Output Characteristics

- Output Current: Varies depending on the driven load, typically between 5A and 20A, providing sufficient current for the generator's excitation winding.

- Output Voltage Range: The output voltage is usually adjustable to meet the excitation requirements of different generators, possibly ranging from DC 0V–100V or higher, depending on the product design.

- Voltage Regulation Accuracy: Achieves high regulation accuracy, generally ±0.5%–±1%. For example, when the set output voltage is 50V, the actual output voltage will be between 49.75V and 50.25V.

3. Control Performance

- Response Time: A fast response time (typically 10ms–50ms) is critical for timely adjustment of the excitation current, enabling rapid adaptation to changes in generator load or grid voltage fluctuations.

- Control Algorithms: Employs advanced control algorithms such as PID control or more complex intelligent control algorithms to achieve precise voltage regulation and stable system operation.

- Communication Interfaces and Protocols: Supports multiple communication interfaces (e.g., RS-485, CAN, Ethernet) and is compatible with common communication protocols (e.g., Modbus, Profibus, OPC) for easy data interaction and remote control with upper-level computers or other control systems.

4. Protection Function Parameters

- Overvoltage Protection: Triggers when the output voltage exceeds a set threshold (typically 120%–150% of the rated output voltage). For example, if the rated output voltage is 50V, overvoltage protection may activate between 60V and 75V.

- Overcurrent Protection: Activates when the output current exceeds a certain proportion of the rated value (usually 150%–200% of the rated output current). For example, if the rated output current is 10A, overcurrent protection may trigger at 15A–20A.

- Undervoltage Protection: The module enters undervoltage protection when the input voltage drops below a set lower limit (generally 80%–90% of the rated input voltage). For a rated input voltage of 220V, undervoltage protection may activate at 176V–198V.

- Overheat Protection: Triggers when the internal temperature of the module exceeds a certain value (typically 80°C–100°C) to prevent equipment damage due to overheating.

5. Operating Environment Parameters

- Operating Temperature Range: Designed for wide industrial environments, typically -20°C–70°C or -40°C–85°C, depending on the product design and application scenario.

- Humidity Range: Capable of operating in high relative humidity environments (generally 5%–95% RH, non-condensing) to ensure stable operation in damp industrial environments.

- Altitude Limit: For equipment used in high-altitude areas, there may be altitude restrictions (e.g., no more than 2000m or 3000m) to account for the impact of thin air on equipment heat dissipation and insulation performance.

Working Principle

As an excitation controller module, the core working principle of ABB PPD117A3011 (3BHE030410R3011) is to ensure stable operation of the power system by real-time monitoring and adjusting the generator's excitation current to control the generator's output voltage and reactive power. The detailed working principle is analyzed as follows:

I. Basic Control Logic

The core objective of the excitation controller module is to maintain constant generator terminal voltage and regulate the reactive power distribution between the generator and the power grid. Its workflow is based on the closed-loop feedback control principle, primarily including the following steps:

- Signal Acquisition

- Voltage Sampling: Real-time detection of the generator's terminal voltage (Ug) via a potential transformer (PT), converting it into an electrical signal recognizable by the module (e.g., analog voltage signal).

- Current Sampling: Monitoring the generator's stator current (Ig) via a current transformer (CT) to calculate reactive power and determine the load status.

- Other Inputs: May receive voltage reference commands (Uref) from upper-level computers, grid frequency signals, or other control parameters.

- Deviation Calculation

- Compare the measured voltage (Ug) with the reference voltage (Uref) to calculate the voltage deviation (ΔU=Uref−Ug).

- If the system needs to regulate reactive power, the reactive power deviation (ΔQ) is also calculated using current signals.

- Control Algorithm Processing

- Proportional (P) Link: Rapidly responds to voltage deviations, outputting an adjustment amount proportional to the deviation.

- Integral (I) Link: Eliminates static errors to ensure long-term voltage stability at the reference value.

- Derivative (D) Link: Predicts the trend of deviation changes, suppresses system overshoot, and improves dynamic response speed.

- The module processes the deviation signal through built-in control algorithms (such as classical PID control, adaptive control, or modern intelligent control algorithms) to generate excitation current adjustment commands (Iexc−ref).

- Example of PID Control:

- Excitation Current Adjustment

- Based on the commands output by the control algorithm, the module adjusts the output current (Iexc) of the excitation power supply through power amplification circuits (such as thyristor rectifiers or IGBT inverters), thereby controlling the magnetic field strength of the generator's excitation winding.

- When the excitation current increases, the generator's magnetic field strengthens, raising the terminal voltage; conversely, the terminal voltage decreases.

II. Key Function Realization

- Voltage Stability Control

- Automatic Adjustment: When the generator load increases (e.g., inductive load increases) and causes the terminal voltage to drop, the module detects the voltage deviation and automatically increases the excitation current to enhance the magnetic field strength, restoring the terminal voltage to the set value.

- Reactive Power Distribution: When multiple generators operate in parallel, the module adjusts the excitation current to change the reactive power output of each generator, ensuring reasonable reactive power distribution in the grid and maintaining the system voltage level.

- Dynamic Response and Protection

- Overvoltage Protection: Rapidly reduces the excitation current when the terminal voltage exceeds the set threshold (e.g., 120% of the rated voltage) to prevent equipment insulation damage.

- Overcurrent Protection: Monitors the excitation current or stator current and triggers current limiting or shutdown protection when the safe limit is exceeded.

- Under-Excitation Limitation: Prevents the generator from operating in the leading power factor condition due to excessively low excitation current, avoiding a decline in system stability.

- Overheat Protection: Monitors the internal temperature of the module via temperature sensors and automatically derates or shuts down when overheating occurs.

- Fast Response: Through high-speed sampling and real-time control algorithms, the module can react to voltage fluctuations within tens of milliseconds, adapting to dynamic scenarios such as sudden changes in generator load or grid faults.

- Multiple Protection Mechanisms:

- Communication and System Integration

- Digital Interfaces: The module supports communication protocols such as Modbus, Profibus, and Ethernet, enabling real-time data exchange (e.g., voltage, current, fault status) with power plant DCS (distributed control systems) or other automation devices.

- Remote Control: Upper-level computer software allows remote setting of voltage reference values, modification of control parameters, or viewing of operating status, enabling intelligent power dispatch.

III. Typical Application Scenarios

- Excitation Control for Synchronous Generators

In thermal power plants, hydropower plants, or industrial captive power stations, the module serves as the core controller of the excitation system to ensure voltage stability and reactive power regulation during single-unit or parallel operation. - Grid Voltage Support

When grid faults (such as short circuits) or sudden load changes cause voltage fluctuations, the module rapidly adjusts the excitation current to provide reactive power support to the grid, suppress voltage dips, and improve system transient stability. - Excitation Control for Motors

In applications with large synchronous motors, the module can adjust the excitation current to optimize the power factor, reduce energy consumption, or provide soft excitation control during motor starting.

IV. Collaboration with Other Equipment

- Coordination with Excitation Power Supplies: Control signals output by the module drive excitation power supplies (such as silicon-controlled rectifier devices) to convert AC power into adjustable DC excitation current.

- Linkage with Protection Devices: When grid protection devices (such as relays) detect faults, the module can receive trip signals to quickly de-energize and cut off the excitation power supply, avoiding fault expansion.

Application Fields

- Power Generation: Used in power plants to control the excitation system of generators and maintain stable generator operation.

- Industrial Applications: Applied to the excitation control of various industrial generator sets or motors to ensure stable and efficient power supply.

- Grid Systems: Helps regulate grid voltage, ensuring stable and efficient operation of the power system and avoiding equipment damage caused by voltage fluctuations.

- Automation Control: Integrated with other control systems to provide precise voltage control and power dispatch.

Related Products

ABB 5SHX14H4502 3BHB003230R0101 IGCT Module

ABB PM867K01 3BSE076355R1 | AC 800M Processor Unit HI Clock

ABB FI820F 3BDH000031R1 | AC 800F Fieldbus Module

ABB CI853K01 3BSE018103R1 | Dual RS232-C Interface Kit

ABB PPD113B01-10-150000 3BHE023784R1023 | Controller Module