Description

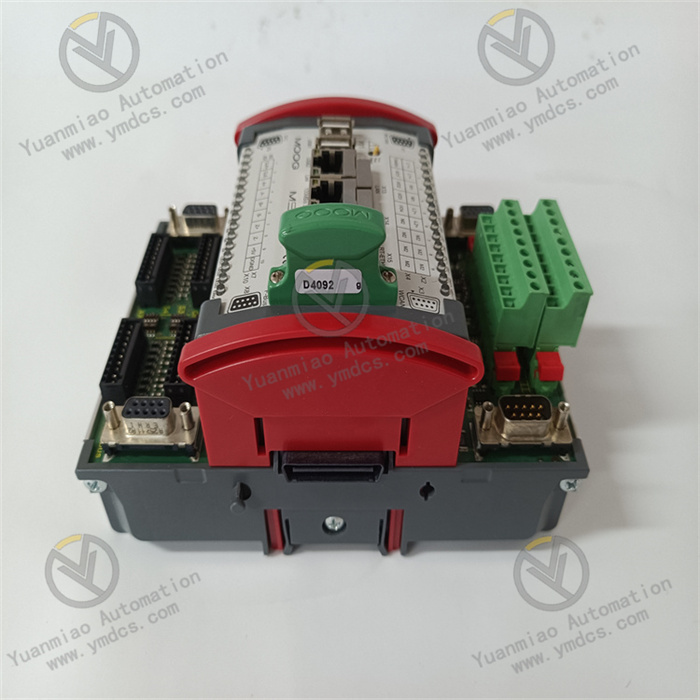

Overview: It is an electro-hydraulic pressure regulating control valve used to position single-acting steam turbine valve servos/actuators. The 10 bar, Zone 2, enhanced-power simplex version addresses industry reliability issues where oil contamination affects equipment uptime and performance.

Technical Parameters: With an input signal of 4-20 mA DC and a typical operating pressure range of 0 to 10 bar (14.5 to 145 psi), it converts the input current signal into a proportional output pressure signal. It features high precision for accurate valve positioning and fast response time to quickly react to changes in input signals.

Functional Features:

- Resistant to oil contamination (ISO20/16), enabling precise fluid pressure control and stable, linear valve control, including a valve linearization table (full range < 0.2%).

- Redundant inputs/sensors for critical applications, with redundant (dual) CPC (master/slave) functionality.

- Provides status and health indicators, including pressure sensor health, input demand signal health, internal unit health, input power quality, etc., and enables control pressure readings.

- Compliant with applicable CE directives—ATEX, Machinery, PED, and EMC.

Application Scenarios: Widely used in process control systems, industrial automation, and pneumatic actuator systems.

- In power plants: Controls generator speed and output voltage.

- In aerospace: Controls engine speed and output power in aircraft and spacecraft propulsion systems.

- In renewable energy systems: Applied to wind turbines or solar tracking systems.

- In mechanical equipment manufacturing: Provides precise motor control.

Operation and Maintenance Recommendations:

- Install and wire correctly according to relevant manuals, ensuring secure connections and avoiding signal interference.

- For parameter configuration, set input/output types, control modes, etc., via corresponding configuration tools or interfaces based on specific application scenarios and control requirements.

- Regularly inspect equipment connections, clean dust from the surface, and perform functional tests and calibrations at specified intervals to ensure performance and accuracy meet requirements.

- In case of faults, use the equipment’s status indicator information, diagnostic functions, or relevant testing tools for troubleshooting and repair.

![]()