Description

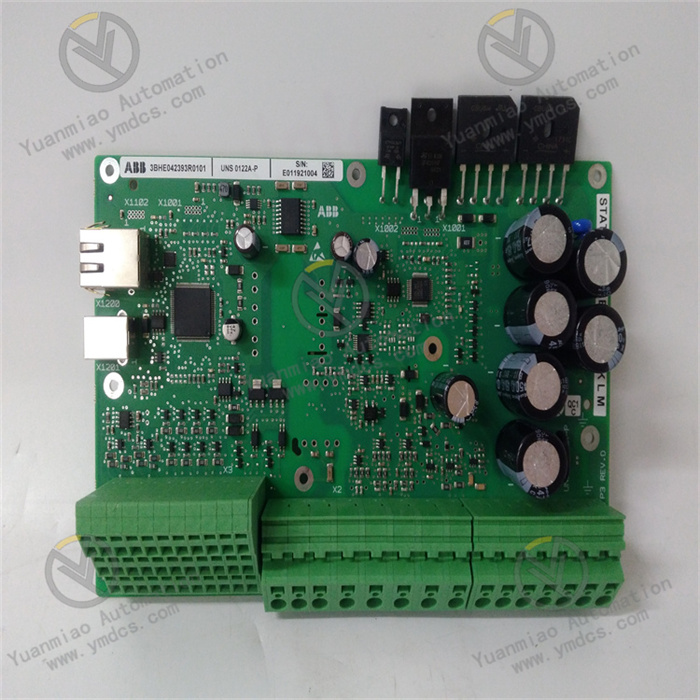

ABB PP877K 3BSE069274R1

The ABB PP877K 3BSE069274R1 is a communication module within the AC800M controller family, designed for distributed control and communication in industrial automation systems. It enables high-speed data interaction between controllers and field devices, other control systems, or supervisory computers, supporting multiple industrial communication protocols.

Functions and Application Scenarios

Core Functions

- Multi-Protocol Communication Support

- Compatible with mainstream industrial protocols such as Modbus RTU, Modbus TCP, and CANopen, adapting to various field devices like sensors, variable frequency drives, and instruments.

- Supports data interaction with third-party devices (e.g., Siemens, Rockwell), enhancing system openness.

- High-Speed Data Transmission

- Equipped with a high-performance processor, supporting real-time data acquisition and transmission to meet the needs of fast-control scenarios (e.g., motion control, real-time process monitoring).

- System Integration and Expansion

- As an expansion module for AC800M controllers, it seamlessly connects to CPU modules via backplane buses (e.g., MasterBus 300) to expand the system’s communication capabilities.

- Multiple communication modules can be cascaded to achieve flexible deployment of multi-network topologies (e.g., star, bus).

- Industrial-Grade Reliability Design

- Operating temperature range: -20°C ~ +60°C, adapting to harsh industrial environments (e.g., high temperature, dust, electromagnetic interference).

- Protection level IP20 (suitable for installation in control cabinets), compliant with IEC 61000 EMC standards, resistant to vibration and shock.

Technical Parameters

| Parameter Category | Detailed Specifications |

|---|---|

| Communication Interfaces | - 2 RS-485 interfaces (supporting Modbus RTU, CANopen) - 1 Ethernet interface (supporting Modbus TCP) |

| Protocol Support | Modbus RTU/TCP, CANopen, custom protocols (requiring programming configuration) |

| Transmission Rate | - RS-485: Up to 115.2 kbps - Ethernet: 10/100 Mbps (auto-negotiation) |

| Power Supply | - Input voltage: 24 VDC (±20%) - Power consumption: Typical value <5 W |

| Physical Characteristics | - Dimensions: Approximately 100 mm (H) × 25 mm (W) × 150 mm (D) - Mounting: DIN Rail mounting |

Working Principle

1. Communication Protocol Processing

- Protocol Parsing and Encapsulation:

Receives commands from the controller (e.g., reading sensor data, controlling device start/stop), encapsulates them into specific format data packets according to the target protocol (e.g., Modbus RTU), and sends them to field devices via RS-485 or Ethernet interfaces. - Example: When reading the frequency of a variable frequency drive via Modbus TCP, the module converts the controller’s request into a TCP frame containing Modbus function codes and register addresses, then sends it to the drive’s IP address.

- Data Interaction Flow:plaintext

Controller (AC800M CPU) → PP877K Module → Protocol Conversion → Field Device Field Device Response → PP877K Module → Protocol Parsing → Controller/Supervisory Computer

2. Coordination with the Controller

- Backplane Bus Communication:

Real-time data exchange with the CPU module via the AC800M series MasterBus 300 bus, with a transmission rate of up to 10 Mbps, ensuring low-latency synchronization of control commands and feedback data. - Data Caching and Scheduling:

Built-in buffers temporarily store data to be sent or received, supporting multi-task scheduling (e.g., simultaneous handling of Modbus RTU and Modbus TCP communications) to avoid data congestion.

3. Fault Handling and Diagnosis

- Self-Diagnosis Function:

Monitors interface status (e.g., communication link disconnection, parity errors), module temperature, and power voltage in real time, displaying operating status via LED indicators (e.g., RUN, FAULT, COMM). - Fault Response Mechanism:

When a communication fault is detected, it automatically retries the connection and logs the fault, while sending alarm signals to the SCADA system via the controller to support remote diagnosis and maintenance.

Typical Application Scenarios

- Manufacturing Production Lines:

Connects robots, PLCs, sensors, and other devices to achieve real-time data monitoring and collaborative control of production lines (e.g., equipment status collection, process parameter distribution). - Process Automation (Chemical/Power):

Connects to field instruments (e.g., flow meters, pressure transmitters) via Modbus RTU, collects process data, and uploads it to the DCS system, supporting closed-loop control (e.g., PID regulation). - Building Automation:

Acts as a BACnet/Modbus gateway to integrate HVAC systems, elevators, and other devices, enabling building energy management and equipment interlocking control. - Distributed Control Systems (DCS):

Serves as a redundant communication node, supporting master-backup module switching to enhance system reliability (e.g., preventing single-point failures in petrochemical scenarios).

Selection and Matching Recommendations

- Supporting Controllers: Must be used with ABB AC800M series CPU modules (e.g., PM866, PM867), configured and programmed via Control Builder M software.

- Expansion Modules: Can be paired with ABB’s I/O modules (e.g., DI810, AO810) to implement integrated "communication + control" solutions.

- Software Support: Use ABB’s Drive Composer or third-party tools (e.g., Modbus Poll) for protocol debugging and parameter configuration.