Description

GE DS2020FEXAG4

I. Product Overview

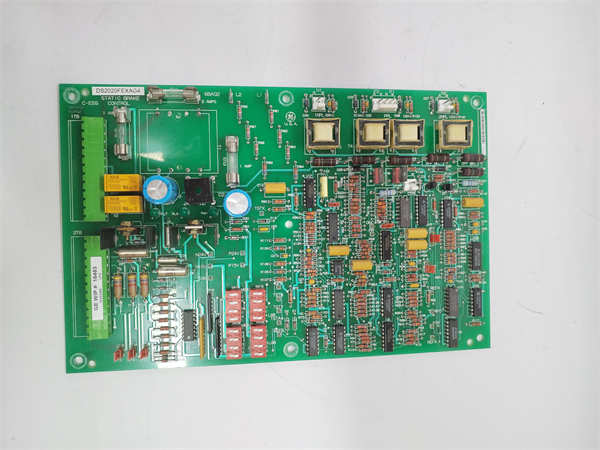

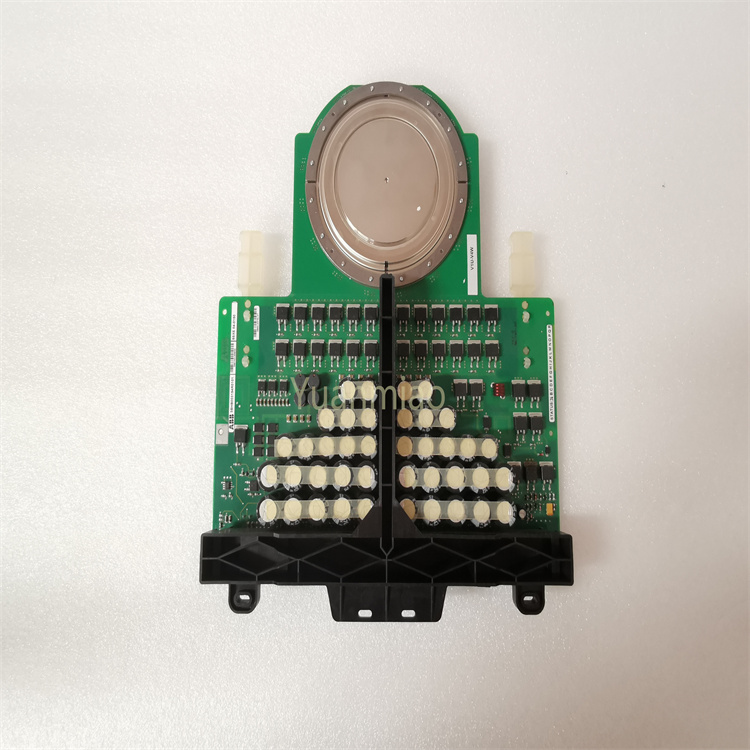

The GE DS2020FEXAG4 is a core excitation triggering module in the Mark VIe series control system, specifically designed for high-power industrial power generation and drive systems. It is positioned as a "dedicated triggering terminal for high-power thyristor excitation power units". Its core function is to receive triggering commands from an excitation control module (such as the DS200FCGDH1B), output synchronous triggering signals through high-precision pulse generation technology, and accurately control the turn-on and turn-off timing of three-phase fully controlled bridge thyristor power units. This enables precise regulation of the excitation current of generators or large synchronous motors. Meanwhile, the module integrates triggering pulse status monitoring, multi-dimensional fault diagnosis, and high-speed communication functions, providing stable and reliable excitation triggering support for key equipment such as high-power generator sets, blast furnace blowers, and large fans in fields including electric power, petrochemicals, and metallurgy.

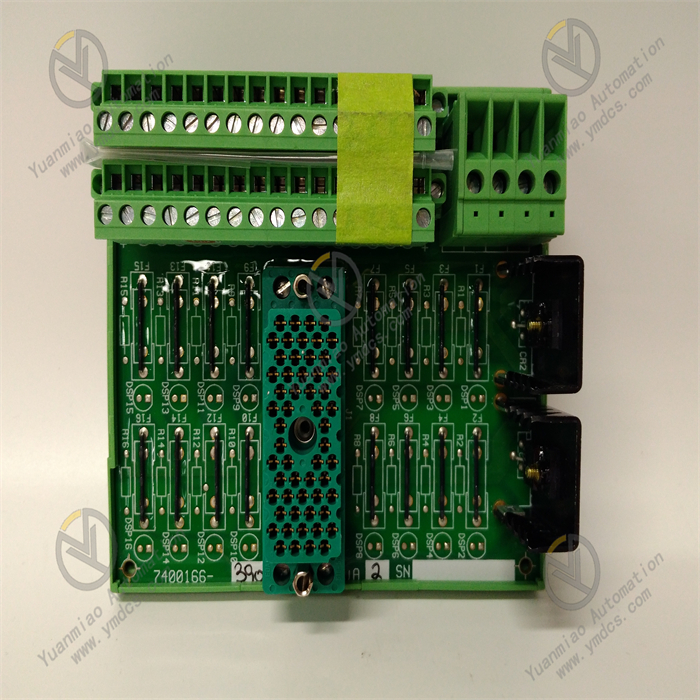

In terms of hardware architecture, the module adopts a design of "high-precision synchronous clock + multi-channel pulse generation + real-time status feedback". Its core consists of a 32-bit industrial-grade DSP processor, a high-precision clock synchronization unit, 6 independent pulse generation circuits, and a multi-protocol communication interface. It is equipped with 2 redundant control command input interfaces (dual-mode of optical fiber + electrical signal; optical fiber transmission distance ≤100m, electrical signal transmission distance ≤10m), 6 thyristor triggering pulse output interfaces, and 2 redundant communication interfaces (supporting EtherNet/IP and CANopen protocols, with a maximum rate of 100Mbps). It has a built-in 16-bit high-precision A/D sampling chip with a sampling frequency of 2kHz, which can collect key parameters in real time, such as pulse amplitude, thyristor anode voltage, and module temperature. In terms of triggering performance, it adopts a composite technology of "Digital Phase-Locked Loop (DPLL) + segmented pulse modulation", with a continuously adjustable triggering angle of 0°-180° and an accuracy of ±0.1°. It supports 50Hz/60Hz self-adaptation and 10Hz-500Hz wide-frequency adjustment, with a configurable pulse width of 50μs-1000μs. In terms of redundancy and protection design, it supports multi-module parallel synchronous triggering (phase consistency error ≤0.2%), adopts a dual mechanism of "hardware fast protection + software logic protection", and has multiple protection functions such as pulse loss protection, overvoltage protection, overtemperature protection, and power reverse connection protection. Its industrial-grade reinforced design allows it to operate stably in environments with a temperature range of -25℃~75℃ and strong electromagnetic interference.

II. Technical Parameters

III. Functional Features

1. High-Precision Pulse Triggering for Reliable Excitation Regulation Accuracy

The module adopts a composite technology of "Digital Phase-Locked Loop + segmented pulse modulation", breaking through the limitations of traditional analog triggering. It has a built-in high-precision DPLL unit that tracks grid synchronous signals in real time, with a synchronization error of ≤0.05°. Combined with the high-speed computing capability of the 32-bit DSP, it realizes continuous adjustment of the triggering angle from 0° to 180° with an accuracy of ±0.1°. To adapt to the characteristics of different thyristors, it supports configurable pulse width of 50μs-1000μs and adopts a segmented modulation strategy: wide pulses are output at the initial stage of conduction to ensure reliable triggering, and narrow pulses are switched after conduction to reduce power consumption. The pulse amplitude is stably maintained at a peak value of ≥15V with a fluctuation of ≤5%, making it suitable for full-range thyristors of 100A-3000A. In terms of dynamic response, the design of high-speed optocouplers and drive circuits enables a command response time of ≤20μs. When the load changes by ±15%, the excitation current returns to stability within 100ms, ensuring a voltage regulation accuracy of ±0.2% when the unit is connected to the grid.

2. Multi-Module Synchronous Triggering for Complex Topology Requirements

It supports multi-module parallel synchronous triggering, achieving precise phase synchronization between master and slave modules through a synchronous clock bus, and is suitable for multi-pulse topologies such as 12-pulse and 24-pulse. The master module sends synchronous clock signals to the slave modules, with a transmission delay of ≤1μs, ensuring a phase consistency error of ≤0.2% among multiple modules. It is equipped with a synchronous fault-tolerant mechanism: when the synchronous signal of the master module is abnormal, the slave modules automatically switch to the grid synchronous signal within 5ms to ensure the continuity of triggering. To meet the phase offset requirements of multi-pulse topologies, a phase offset of -30°~+30° can be set through configuration software, enabling adaptation to different topologies without modifying hardware. For example, in a 24-pulse system, 4 modules are connected in parallel, with phase offsets set to 0°, 15°, 30°, and 45° respectively. This results in the excitation current harmonic content being ≤2%, significantly reducing grid pollution. The dual-mode command input (optical fiber + electrical signal) can be flexibly selected according to the distance between cabinets, improving the flexibility of system layout.

3. Triple Protection Mechanism for Enhanced Operational Safety

4. Strong Anti-Interference Design for Harsh Industrial Environments

5. Convenient Configuration & Maintenance for Reduced O&M Costs