Description

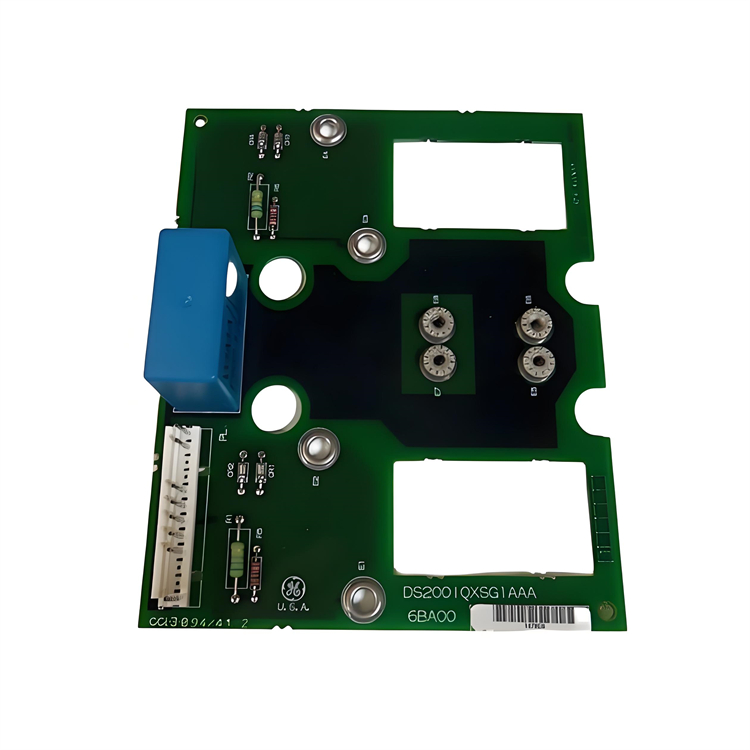

GE DS200IIBDG1AFA

GE DS200IIBDG1AFA is a medium-sized frequency converter produced by GE Digital, mainly used to control AC induction motors, and is widely applicable to various motor application scenarios.

Functional Features:

- High Performance: The output frequency range is 0.5Hz to 200Hz, which can meet the needs of various motor applications. The efficiency exceeds 95%, which can effectively reduce energy consumption.

- High Reliability: Adopting advanced control technology and high-quality components to ensure stable operation. It has an overload capacity of 150% and can last for 1 minute, which can cope with a certain degree of sudden load changes.

- Easy to Use: Provides multiple operating modes, and users can choose according to actual conditions. It has rich functions such as programming and fault diagnosis, which is convenient for users to set up and maintain the equipment.

- Convenient Communication: Supports multiple communication protocols such as RS485, Modbus RTU, and CAN, and can communicate with the upper system or other equipment, facilitating integration into complex industrial control systems.

- Strong Processing Capacity: It can quickly process a large amount of data and can timely respond to and process various signals related to motor control.

- High Safety: It has a certain anti-interference ability, which can protect industrial processes and machines from external interference and attacks, ensuring the stable operation of the system.

Technical Parameters:

- Output Frequency: 0.5Hz to 200Hz.

- Efficiency: Over 95%.

- Overload Capacity: 150% rated load for 1 minute.

- Communication Interfaces: Supports RS485, Modbus RTU, CAN, etc. Some may also support other interfaces such as Ethernet.

Working Principle: DS200IIBDG1AFA receives command signals from the control system, such as speed set values and torque set values, and uses internal control circuits and algorithms to convert DC power into AC power with adjustable frequency and voltage, which is output to the AC induction motor, thereby controlling the speed and torque of the motor. During operation, the frequency converter will monitor parameters such as current, voltage, and temperature of the motor in real-time. When abnormalities occur, such as overcurrent and overvoltage, it will trigger the internal protection mechanism, stop output or take corresponding protective measures to protect the motor and the frequency converter itself. At the same time, it can also conduct data interaction with the upper computer or other equipment through the communication interface, upload motor operating status information or receive new control commands.