Description

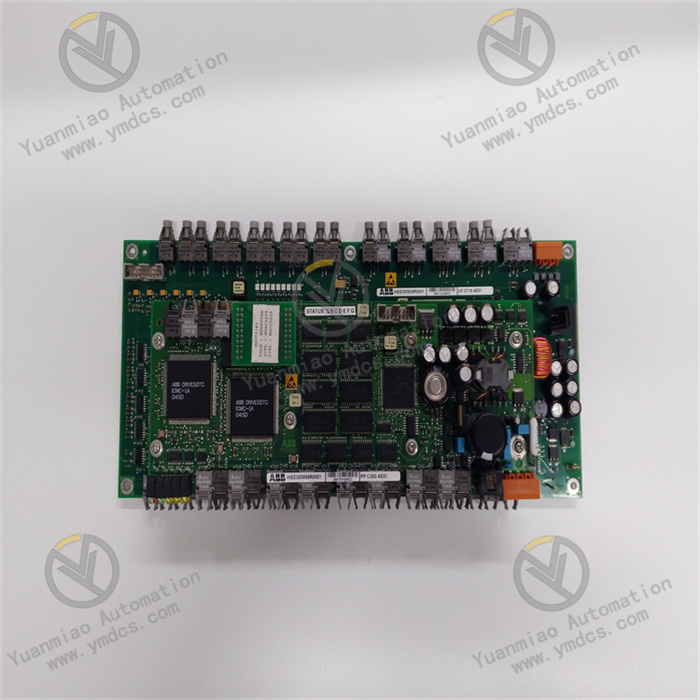

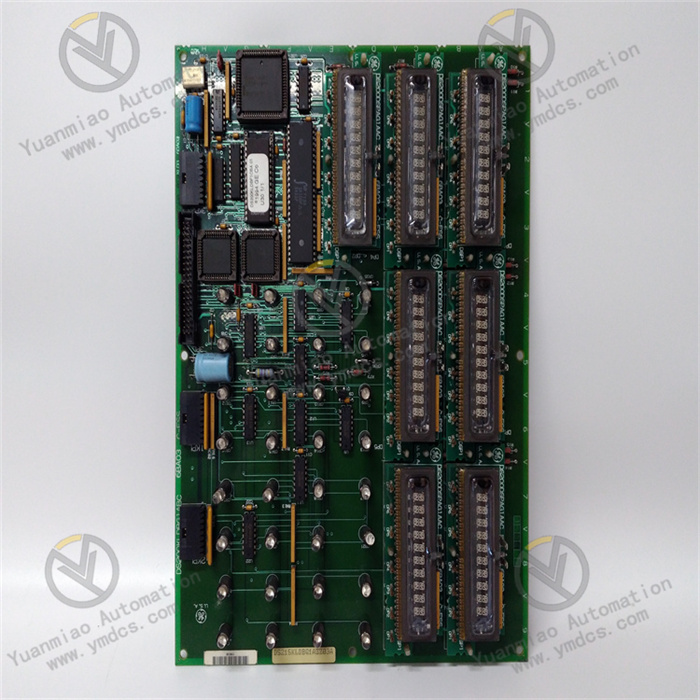

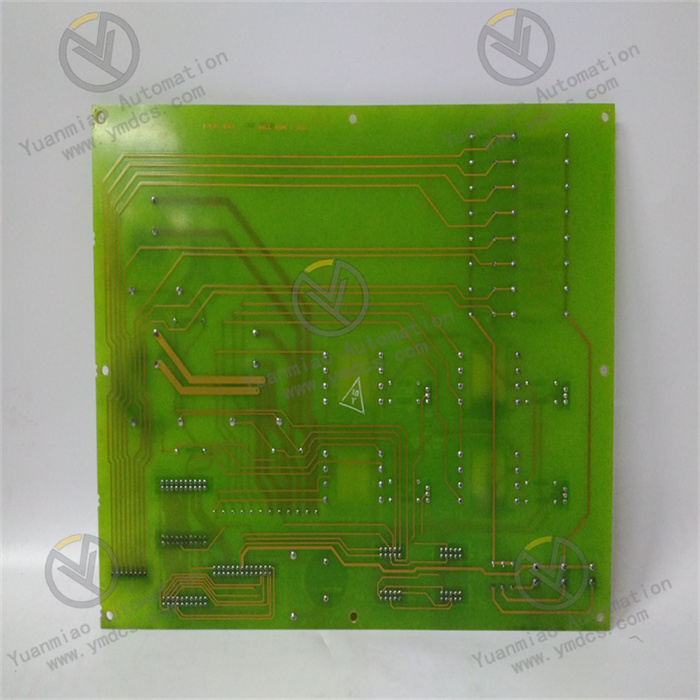

GE DS200TCEBG1ACE

Overview

The GE DS200TCEBG1ACE is a specialized industrial control component designed for complex automation systems, mainly used in power generation, petrochemical, and heavy machinery control scenarios. As a key part of GE's DS200 series, this device serves as a terminal board or control module, focusing on analog signal processing, system interface expansion, and real-time data transmission. It enables seamless integration with sensors, actuators, and supervisory control systems, ensuring stable operation and precise monitoring in harsh industrial environments.

Technical Parameters

- Power Supply:

- Voltage: 24V DC (with ±10% tolerance)

- Power Consumption: ≤12W

- Electrical Specifications:

- Input Range: -10V to +10V (for analog signals)

- Output Range: 4-20mA (standard industrial current loop)

- Isolation Voltage: 2500Vrms (between input and output channels)

- Communication:

- Interface: RS485 (supporting Modbus RTU protocol)

- Baud Rate: Configurable from 9600 to 115200 bps

- Mechanical & Environmental:

- Dimensions: 140mm × 90mm × 45mm

- Operating Temperature: -20°C to +70°C

- Protection Level: IP20 (dust-resistant, non-waterproof)

Working Principle

The DS200TCEBG1ACE functions as an analog signal conditioning and transmission hub, with its core working principles as follows:

- Signal Acquisition: Converting physical parameters (such as temperature, pressure, and flow) from sensors into electrical signals (voltage or current) for subsequent processing.

- Signal Conditioning: Amplifying and filtering raw signals through built-in operational amplifiers and analog filter circuits to eliminate noise and ensure measurement accuracy.

- Electrical Isolation: Adopting optocoupler or magnetic isolation technology to separate input and output circuits, effectively preventing ground loop interference and electromagnetic interference (EMI), and ensuring stable signal transmission.

- Protocol Conversion: Translating analog signals into digital data compatible with industrial communication protocols (e.g., Modbus) to enable seamless integration with PLCs, SCADA systems, or other control devices.

- Fault Diagnosis: Implementing real-time monitoring of signal integrity, and triggering alarm signals via built-in logic circuits in case of over-range, under-range, or open-circuit faults to ensure system safety.