Description

ABB PPD113B01-23-111000 3BHE023784R2330

- Environmental Adaptability:

Supports wide-temperature operation (e.g., -20°C to +60°C), vibration/shock resistance (compliant with industrial standards such as IEC 61131-2), suitable for harsh industrial environments (e.g., factory workshops, production lines). - Redundancy & Protection:

May support power redundancy and channel isolation (surge protection, overvoltage protection) to minimize failures caused by external interference.

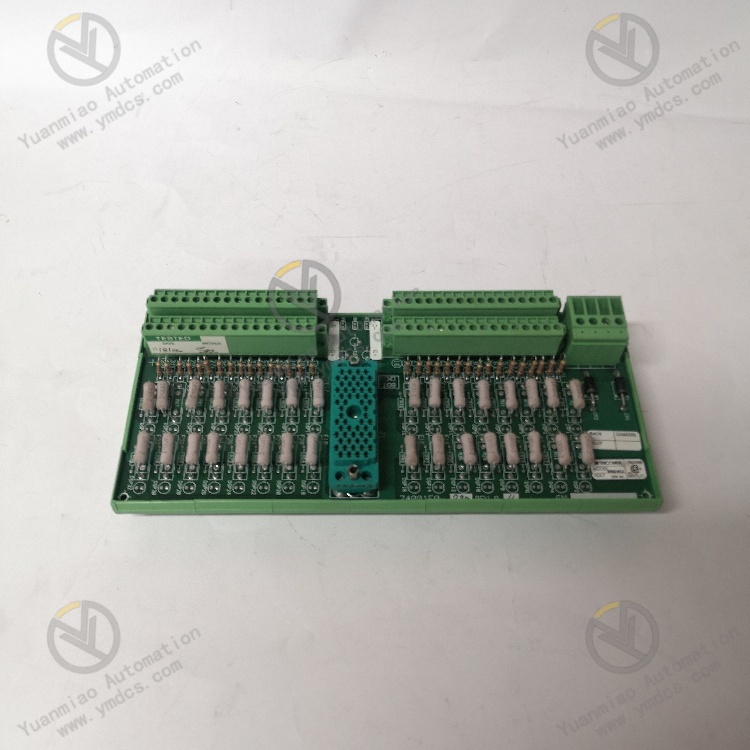

- Multi-Type Interfaces:

May integrate digital inputs/outputs (DI/DO) and analog inputs/outputs (AI/AO), supporting various signal types (e.g., 24V DC, 4-20mA, 0-10V). - Expandability:

Supports expansion of distributed I/O modules via industrial buses (e.g., PROFIBUS, EtherCAT, Modbus) for complex control systems.

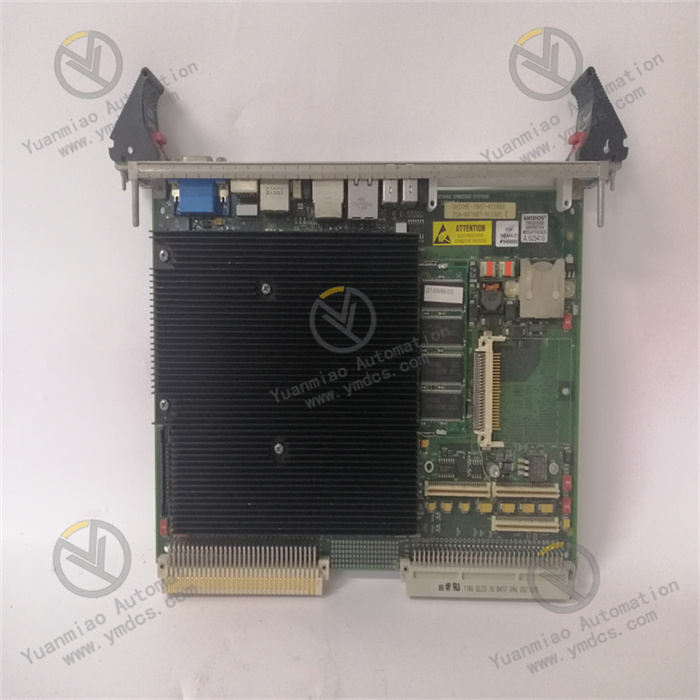

- Processor Performance:

Equipped with a high-speed CPU supporting real-time operating systems (RTOS), capable of handling complex logic control, PID regulation, etc., with short scan cycles (e.g., millisecond-level). - Storage Capacity:

Features large-capacity memory (e.g., Flash/RAM) for program storage and data logging, may include built-in databases or recipe management.

- Mainstream Industrial Buses:

Supports communication protocols such as Ethernet/IP, PROFINET, Modbus TCP for seamless integration with PLCs, DCS, SCADA systems, or host computers. - Real-Time Data Interaction:

Supports master-slave mode for real-time data synchronization between devices, meeting data transmission requirements for Industrial IoT (IIoT) or smart manufacturing.

- Programming & Configuration:

Compatible with ABB's official programming software (e.g., Control Builder for AC 800M), supporting IEC 61131-3 standard programming languages (Ladder, ST, SFC, etc.). - Diagnosis & Maintenance:

Built-in fault self-diagnosis (e.g., channel status indicators, error code prompts), supports remote monitoring and firmware upgrades to reduce maintenance costs.

- Low-Power Architecture:

Utilizes efficient power management with low standby power consumption, compliant with industrial energy-saving standards. - Modular Installation:

Supports DIN rail mounting, compact structure, hot-swappable (on some models) for quick field replacement.

- Processor: 32-bit 120MHz DSP microprocessor.

- Brightness Control: 256-level brightness adjustment.

- I/O Interfaces:

- 16 optically isolated digital I/Os (8 inputs, 8 bidirectional I/Os).

- High-speed hardware Register function input interface per axis.

- One optically isolated 0-10V analog input channel.

- Expandable I/O via CAN bus: up to 256 digital I/Os (24V) and 32 analog I/Os (±10V).

- Communication Interfaces:

- Standard module: 2 RS232 ports, 1 RS485 port, 1 TTL interface, 1 USB interface, 1 CAN interface.

- Port1 (RS232) or Port2 (RS485) configurable for MODBUS protocol.

- CAN interface supports CAN protocol or DeviceNet (when not used for I/O expansion), enabling slave-mode communication in DeviceNet networks.

- Built-in USB interface for programming or communication via Trio's ActiveX controls. Optional Profibus communication sub-board for Profibus slave operation.

- Other Functions:

- External trigger input for strobe lighting control (e.g., camera synchronization), extending light source lifespan.

- PC controllable via serial/network interface, with brightness adjustment and communication demo for easy integration.

- Optional manual control for on-site brightness adjustment.

- Power-down data retention.

Industrial Automation Control: Logic control for production lines, motor start/stop control, valve regulation, etc.

Process Monitoring Systems: Real-time sensor data acquisition (temperature, pressure, flow) for closed-loop control.

Energy Management: Power systems, water treatment, HVAC optimization for energy efficiency.

Machine Integration: Core controller for OEM equipment such as packaging machinery and printing presses.

Products of other brands

GE IS200TSVCH1AED Servo Input/Output Terminal Board

GE IS200STCIH6AED | Control Circuit Board

BENTLY 3500/15 114M5335-01 DC Power Supply Module

Bently 1900/65A-00-00-01-00-01 General Purpose Equipment Monitor

Woodward 9907-162 | 505 Digital Governor Steam Turbines

Triconex 3805E | Analog Output Module

![]()