Description

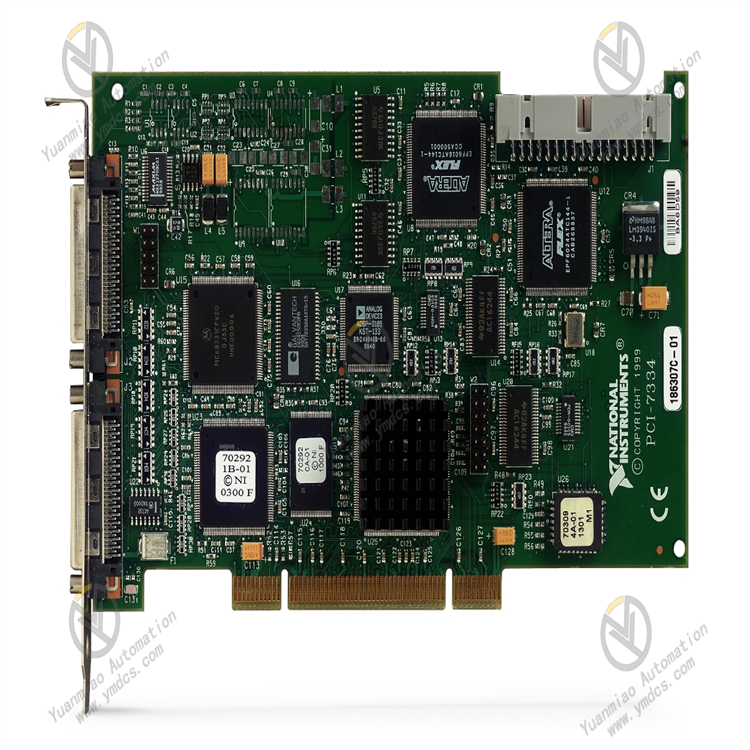

The NI PCI-7342 is a high-performance motion control card launched by National Instruments (NI) in the United States. Based on the PCI bus interface, it is mainly used in fields such as industrial automation, robot control, and precision positioning to achieve precise control of stepper motors or servo motors.

Functional Features

Multi-axis Control Capability: It supports synchronous motion control of up to 4 axes, and can coordinate the control of multiple motors simultaneously to meet the requirements of complex motion trajectories. For example, in the motion control of a robotic arm, it can achieve the coordinated actions of multiple joints to complete precise grasping and placing operations.

Flexible Motion Modes: It has a variety of motion modes, such as point-to-point motion, continuous path motion, speed control, torque control, etc. Users can select appropriate motion modes according to specific application requirements to achieve precise positioning and motion control. For instance, in the processing of CNC machine tools, different motion modes can be selected according to the processing technology requirements to ensure processing accuracy and efficiency.

High-precision Position Feedback: It can be connected to various types of position feedback devices, such as encoders, and can obtain the position information of the motor in real time to achieve high-precision closed-loop control. Through the real-time processing and adjustment of the position feedback signal, the motion accuracy and stability of the motor are guaranteed.

High-speed Data Transmission: By adopting the PCI bus interface, it realizes high-speed data transmission between the computer and itself, ensuring the rapid sending of motion control commands and the timely reception of feedback data, and improving the response speed and real-time performance of the system.

Rich Software Support: It supports a variety of software development platforms such as NI's LabVIEW and LabWindows/CVI, and provides rich function libraries and toolkits, which are convenient for users to program and integrate the system. Users can select appropriate development environments according to their own programming habits and project requirements, and quickly develop customized motion control systems. Technical Parameters

Maximum Output Pulse Frequency: It can usually reach a relatively high pulse output frequency, such as 20MHz, which can meet the requirements of high-speed motion control and achieve the rapid response and precise control of the motor.

Position Resolution: It has a high position resolution and can achieve precise control of the motor position. For example, the position resolution per revolution can reach thousands or even tens of thousands of pulses, ensuring the accuracy of motion control.

Input and Output Interfaces: It is equipped with rich input and output interfaces, including digital input and output ports, analog input and output ports, etc. The digital input and output ports can be used to connect external sensors and actuators to achieve signal acquisition and control; the analog input and output ports can be used to connect analog devices, such as analog sensors and analog controllers, to expand the functions of the system.

Operating Temperature Range: Generally, the operating temperature range is from 0°C to 55°C, and it can work stably under certain ambient temperature conditions, adapting to the environmental requirements of most industrial sites.

Application Areas

Industrial Automation Production Lines: It is used in the links such as material handling, assembly, and inspection on the automation production line to achieve precise motion control of equipment such as robotic arms and conveyor belts, and improve production efficiency and product quality.

Robot Technology: In the fields of industrial robots, service robots, scientific research robots, etc., as the core component of the robot's motion control system, it realizes the precise motion control and trajectory planning of the robot, enabling it to complete various complex tasks.

CNC Machine Tools: In CNC machine tools, it realizes the precise position control and motion trajectory planning of the tool, ensures the processing accuracy and surface quality, and improves the processing capacity and production efficiency of the machine tool.

Electronic Manufacturing Equipment: In electronic manufacturing equipment, such as chip mounters and semiconductor packaging equipment, it is used to control the precise motion of the equipment, achieve the accurate installation and processing of electronic components, and ensure the quality and performance of electronic products.

Technical Parameters

Maximum Output Pulse Frequency: It can usually reach a relatively high pulse output frequency, such as 20MHz, which can meet the requirements of high-speed motion control and achieve the rapid response and precise control of the motor.

Position Resolution: It has a high position resolution and can achieve precise control of the motor position. For example, the position resolution per revolution can reach thousands or even tens of thousands of pulses, ensuring the accuracy of motion control.

Input and Output Interfaces: It is equipped with rich input and output interfaces, including digital input and output ports, analog input and output ports, etc. The digital input and output ports can be used to connect external sensors and actuators to achieve signal acquisition and control; the analog input and output ports can be used to connect analog devices, such as analog sensors and analog controllers, to expand the functions of the system.

Operating Temperature Range: Generally, the operating temperature range is from 0°C to 55°C, and it can work stably under certain ambient temperature conditions, adapting to the environmental requirements of most industrial sites.

Application Areas

Industrial Automation Production Lines: It is used in the links such as material handling, assembly, and inspection on the automation production line to achieve precise motion control of equipment such as robotic arms and conveyor belts, and improve production efficiency and product quality.

Robot Technology: In the fields of industrial robots, service robots, scientific research robots, etc., as the core component of the robot's motion control system, it realizes the precise motion control and trajectory planning of the robot, enabling it to complete various complex tasks.

CNC Machine Tools: In CNC machine tools, it realizes the precise position control and motion trajectory planning of the tool, ensures the processing accuracy and surface quality, and improves the processing capacity and production efficiency of the machine tool.

Electronic Manufacturing Equipment: In electronic manufacturing equipment, such as chip mounters and semiconductor packaging equipment, it is used to control the precise motion of the equipment, achieve the accurate installation and processing of electronic components, and ensure the quality and performance of electronic products.