Description

GE Multilin 369-HI-0-M-F-E-0

The GE Multilin 369-HI-0-M-F-E-0 is an enhanced integrated protection relay for medium-voltage and high-voltage motors. Upgraded based on the core architecture of the basic 369 series, it is customized specifically for medium-voltage and high-voltage (rated voltage ≤ 20kV), medium-power and high-power (rated power ≥ 2MW) asynchronous motors, synchronous motors, and special rotating equipment. Positioned as an "intelligent protection and multi-functional monitoring terminal for medium-voltage and high-voltage motors", its core value lies in integrating high-precision electrical quantity acquisition, vibration monitoring expansion, enhanced fault recording, and multi-protocol communication adaptation capabilities. It enables precise protection and multi-dimensional monitoring throughout the entire lifecycle of motor startup, operation, and shutdown, while integrating extended functions such as equipment health diagnosis, remote operation and maintenance, and logical interlocking. It provides an integrated "protection-monitoring-diagnosis-linkage" solution for key equipment like fans, water pumps, compressors, and traction motors in fields including electric power, petrochemicals, metallurgy, and rail transit.

With core advantages of "precise protection, flexible expansion, comprehensive data, and efficient operation & maintenance", this relay is highly adaptable to the operational requirements of medium-voltage and high-voltage motors, such as high load fluctuations, frequent startups/shutdowns, and complex working conditions. It serves as a key component for the closed-loop management of "fault early warning-rapid handling-root cause analysis-health management" in industrial motor control systems. It delivers outstanding performance in key industry scenarios:

- In the electric power sector, it is used to protect denitrification fans and desulfurization pump motors in thermal power plants. Through integrated diagnosis of vibration and electrical quantities, it accurately identifies hidden faults such as bearing wear and rotor imbalance, issues early warnings more than 20 days in advance, and reduces the unplanned shutdown rate by 45%.

- In the petrochemical sector, it is adapted for agitator motors of reactors in refining and chemical plants. With enhanced heat dissipation and sealing designs, it maintains a protection action accuracy of ≥ 99.8% in high-temperature and high-corrosion environments.

- In the rail transit sector, it provides wide-range protection for motors supporting traction converter systems. It adapts to extreme scenarios with grid voltage fluctuations of ±15%, ensuring the stable operation of traction systems.

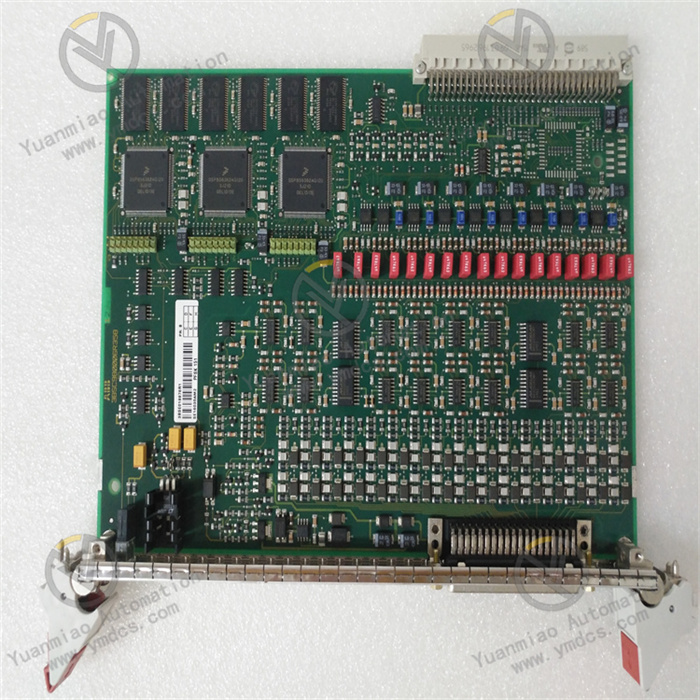

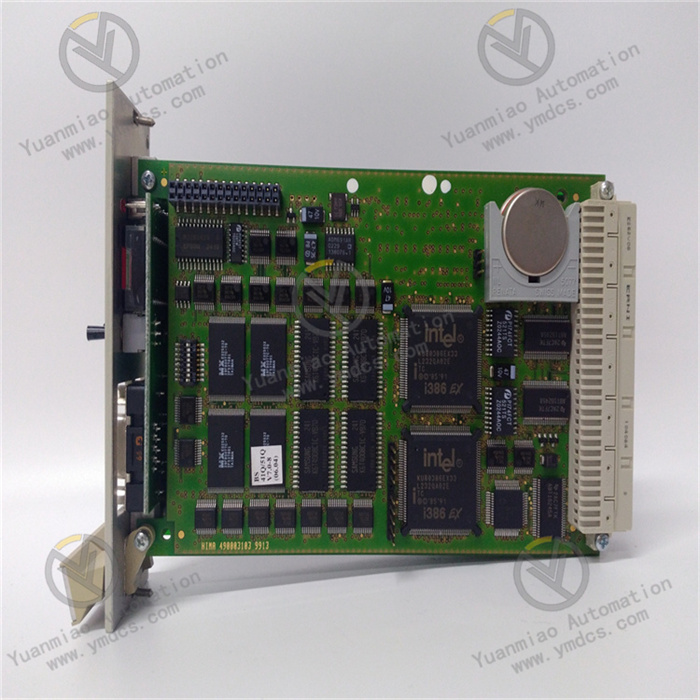

The hardware architecture adopts a high-performance design of "dual-core processor + high-precision acquisition + modular expansion". Its core consists of a 32-bit dual-core industrial-grade processor, a 20-bit high-precision A/D sampling chip, 8 independent protection output interfaces, and a multi-protocol redundant communication module. It is equipped with 4-phase current input channels (compatible with programmable CT ratios from 1:1 to 1:10,000, supporting dual-CT parallel redundant acquisition and open-circuit detection), 3 voltage input channels (compatible with multiple voltage levels of 100V/220V/400V, supporting PT open-circuit detection and voltage balance monitoring), 16 digital input channels (including 4 high-speed DIs with a response time of ≤ 1μs), and 8 relay output channels (with a capacity of AC250V/8A and DC24V/12A, supporting custom functions like tripping, alarming, and interlocking control). It features three built-in communication interfaces: RS485, EtherNet/IP, and Profinet (expansion module), enabling seamless integration with mainstream monitoring systems such as GE CIMPLICITY, Siemens WinCC, and Schneider EcoStruxure. Its protection functions cover more than 25 types of motor faults, including overload (optional inverse-time/definite-time/energy accumulation type), short circuit (instantaneous trip/delayed instantaneous trip/time-limited instantaneous trip), grounding (zero-sequence current/residual current/directional grounding), locked rotor, phase loss, under-voltage/over-voltage/voltage unbalance, rotor bar breakage, winding temperature, bearing temperature, and excessive vibration. It supports custom logical interlocking relationships via GE EnerVista configuration software. The industrial-grade reinforced design uses industrial-grade wide-temperature components (-40℃~75℃), a double-layer metal shielded enclosure (shielding effectiveness ≥ 90dB), and enhanced anti-electromagnetic interference circuits. Complying with high international standards such as IEC 61850-3 and IEC 60255-22-2, it can operate stably in industrial sites with strong electromagnetic interference, high dust, high humidity, and high altitude (≤ 4,000m).

Breaking through the limitations of traditional single electrical quantity protection, a three-dimensional integrated protection system of "electrical parameters + temperature + vibration" is built to adapt to the multi-condition operation requirements of medium-voltage and high-voltage motors.

- For electrical protection: It adopts 192-point/cycle high-precision sampling and dual-core processor parallel computing, with a short-circuit protection action time of ≤ 10ms. This enables rapid interruption of short-circuit faults in 20kV systems, reducing the impact damage of fault energy release on motor insulation. The overload protection supports an energy accumulation action mode, which calculates heat accumulation in real time based on the motor heating model, accurately matching protection needs under variable load conditions and avoiding false tripping under light loads and failure to trip under heavy loads.

- For temperature protection: 8 high-precision temperature input channels can simultaneously monitor the temperatures of key components such as stator windings, rotors, and front/rear bearings. It supports a dual-alarm mechanism of temperature set-value alarm and temperature rise rate alarm (≥ 8℃/min), issuing graded commands of alarm, load reduction, and tripping to slow down insulation aging.

- As a core highlight of expansion, vibration protection features 2 vibration input channels compatible with industrial vibration sensors, which monitor the radial/axial vibration of the motor in real time. Combined with the vibration threshold database in the equipment ledger, it achieves adaptive protection under different speeds. When vibration exceeds the standard, it can link to reduce the load, preventing the expansion of mechanical faults.

- Rotor bar breakage protection integrates current spectrum analysis and auxiliary vibration characteristic diagnosis. It extracts fault characteristic frequencies (e.g., 2sf±f1) through the FFT algorithm, improving the bar breakage detection accuracy from 0.3% (of the basic model) to 0.2% and enabling early warning of hidden faults.

Adopting a flexible architecture of "basic core + expansion modules", it realizes on-demand function configuration through 3 reserved standardized module slots, adapting to the personalized needs of different industry scenarios. Key expansion capabilities include:

- Vibration monitoring module: Provides 2-channel vibration signal acquisition and analysis functions, supporting peak-to-peak, effective value, and frequency spectrum analysis. It is suitable for mechanical fault diagnosis of rotating equipment such as fans and water pumps.

- Profinet communication module: Supports IRT real-time industrial Ethernet communication, meeting the high-speed data interaction needs of Siemens automation systems with a communication delay of ≤ 1ms.

- Oil quality monitoring module (optional): After connecting to an oil quality sensor, it can monitor parameters such as moisture content and dielectric loss value, adapting to condition monitoring of lubrication equipment like gearboxes and hydraulic systems.

- GPS clock synchronization module (optional): Achieves a time synchronization accuracy of ±1μs, meeting the requirement for event timing consistency in multi-equipment linkage scenarios.

Hardware expansion requires no modification to the core circuit; expansion functions can be activated with one click via GE EnerVista software, making the configuration process simple and efficient. In addition, the current input supports dual-CT parallel redundant acquisition—if the main acquisition channel fails, the backup channel automatically takes over within 5ms, with an acquisition accuracy deviation of ≤ 0.05%. The communication system supports automatic switching between main and backup links; if the main EtherNet/IP link is interrupted, it switches to the RS485 backup link within 100ms, ensuring continuous data transmission.

It integrates massive data recording and basic health diagnosis functions, providing data support for the transformation of operation and maintenance management from "post-failure maintenance" to "predictive maintenance".

- Data recording capabilities are fully upgraded: The number of fault oscillography records is increased from 150 (of the basic model) to 200, with each record containing complete electrical and vibration data of 20 cycles before the fault, 10 cycles during the fault, and 30 cycles after the fault, and a sampling resolution of 1ms—providing a complete data chain for fault cause analysis. The number of event records is expanded to 1,000, covering key events such as protection actions, parameter modifications, module insertion/extraction, and communication status, with a timestamp accuracy of ±1s, facilitating the tracing of operation history. The trend data storage duration is extended from 6 months to 1 year (1-minute sampling interval), enabling long-term tracking of parameter changes such as current, voltage, temperature, and vibration.

- For intelligent diagnosis: A built-in motor health assessment model establishes a normal operation baseline based on historical data. When real-time data deviates from the baseline by ±5%, it automatically initiates the diagnosis process, identifies fault types (e.g., bearing wear, uneven air gap, rotor bar breakage), and locates fault locations, with a diagnosis accuracy of ≥ 90%.It supports data export via USB interface or EtherNet/IP network. Combined with GE EnerVista software, it enables waveform analysis, trend statistics, and health report generation. Remote functions such as protection parameter configuration, real-time data collection, and fault diagnosis can be implemented, improving operation and maintenance efficiency by more than 60%.

It adopts an anti-interference design of "double-layer shielding + photoelectric isolation + EMC enhancement" and passes the IEC 61000-4 series anti-interference tests (IEC 61000-4-3 radio frequency radiation immunity: 10V/m; IEC 61000-4-5 surge immunity: 4kV).

- The enclosure uses a double-layer metal shielding structure: the inner layer is a 0.8mm copper foil shielding layer, and the outer layer is a high-strength galvanized steel plate. A shielding network is formed through multi-point grounding, with a shielding effectiveness of ≥ 90dB—5dB higher than the basic model—capable of resisting strong electromagnetic interference generated by the opening and closing of circuit breakers in high-voltage switchgear.

- The signal input circuit adopts photoelectric isolation technology with an isolation voltage of ≥ 3kVrms, blocking common-mode interference and differential-mode interference to avoid damage from on-site high-voltage signal impacts.

- The power supply circuit is equipped with a three-stage EMC filter to filter out power grid harmonics (3rd, 5th, 7th orders) and pulse interference. When the power supply voltage fluctuates in the wide range of 85V~265V, the output voltage stability is ±0.8%.

For wide environmental adaptability design:

- Industrial-grade wide-temperature components (-40℃~75℃) are selected, combined with an intelligent heat dissipation air duct (the fan automatically starts when the temperature ≥ 65℃), ensuring stable operation in high-cold mines in Northeast China and high-temperature workshops in South China.

- The enclosure adopts an IP45 protection class sealing design, with double sealing via a silicone gasket and a metal pressure strip, effectively preventing dust and moisture intrusion. It is suitable for dusty and high-humidity scenarios such as petrochemicals and metallurgy.

![]()