Description

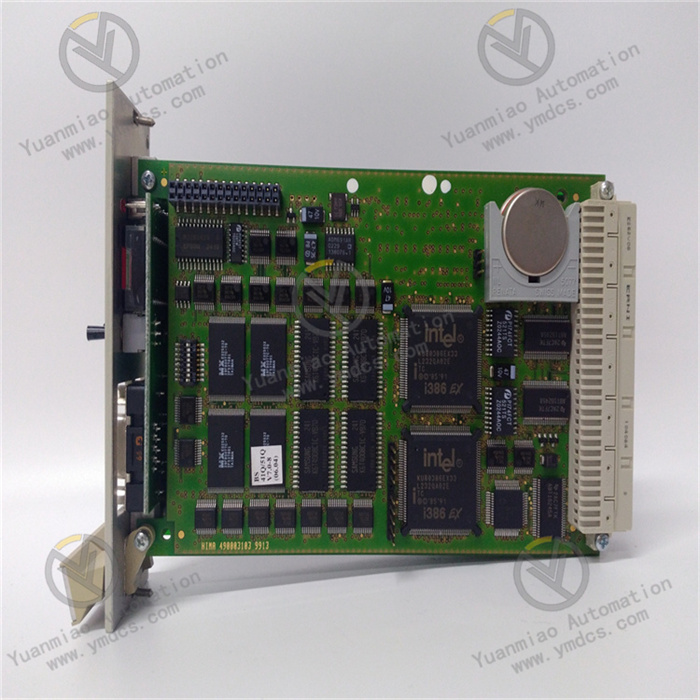

ABB PCD231B101 3BHE025541R0101

The ABB PCD231B101 3BHE025541R0101 is a processor control module in static excitation systems, primarily used to provide reliable and stable excitation for synchronous generators. It employs advanced control algorithms to regulate generator voltage, ensuring stable operation under varying load and grid conditions. The system can be easily integrated with generator control systems and supports multiple communication interfaces for remote monitoring. It is widely applied in industries such as power generation, oil & gas, marine, and mining, suitable for any synchronous generator application requiring reliable and stable excitation.

Functional Features

- High-Performance Control Capability

- Real-Time Data Processing: Supports high-speed data acquisition and processing to meet real-time control requirements.

- Multitask Handling: Can simultaneously execute multiple tasks such as logic control, PID regulation, and sequential control.

- Computational Power: Features floating-point arithmetic, mathematical functions, and logical operations, suitable for complex control algorithms.

- Rich Interfaces and Communication Functions

- Input/Output (I/O) Interfaces:

May integrate analog inputs/outputs (e.g., 4-20mA, 0-10V) and digital inputs/outputs (DI/DO).

Supports expandable I/O modules connected via fieldbuses (e.g., PROFIBUS, PROFINET, Modbus). - Communication Protocols:

Supports industrial Ethernet (e.g., Ethernet/IP, Modbus TCP) and fieldbuses for data interaction with host computers or other devices.

May include an OPC UA interface for easy integration with industrial IoT (IIoT). - High Reliability and Stability

- Industrial-Grade Design:

Adaptable to harsh environments (e.g., high temperature, vibration, electromagnetic interference) and compliant with industrial standards (e.g., IEC 61131-2).

Supports redundant configurations (e.g., power redundancy, communication redundancy) to reduce system downtime risks. - Fault Diagnosis and Self-Testing:

Built-in diagnostic functions to monitor module status in real time (e.g., power failures, communication interruptions), with alarm indicators via LEDs or software. - Flexible Programming and Configuration

- Programming Languages: Supports IEC 61131-3 standard languages (e.g., Ladder Diagram LD, Structured Text ST, Function Block Diagram FBD).

- Configuration Tools: Allows parameter configuration, program downloading, and debugging via ABB official software (e.g., Control Builder, AC 800M).

- System Integration and Scalability

- Modular Design: Enables seamless integration with other ABB products (e.g., PLCs, variable frequency drives, sensors) to build complete automation systems.

- Firmware Upgrades: Supports firmware updates via software tools for functional extensions or compatibility optimizations.

Technical Parameters

- Power Supply

- Power Voltage: IP 65 unit (NEMA 4) 24 V DC.

- Power Consumption: 8 W (24 V); +5V@250mA, +3.3V@10mA.

- Fuse: IP 65 unit (NEMA 4) slow-blow type, 2A, 250V.

- Electrical Characteristics

- Current: 0.5A rms, 330Hz.

- Number of Inputs: 2.

- Input Impedance: 10kΩ.

- Operating Environment

- Operating Temperature: +5 to +55°C (32–131°F).

- Non-Operating Temperature: -40 to +70°C (-40–158°F).

- Physical Characteristics

- Dimensions (Height x Width x Depth): 180 x 120 x 100mm.

- Weight: 1.9 kg.

Common Faults and Solutions for ABB PCD231B101 3BHE025541R01 Industrial Control Module

I. Common Fault Types and Possible Causes

- Power Supply Faults

- Symptoms: No power to the module, indicator lights off, frequent restarts.

- Possible Causes:

Abnormal external power input (unstable voltage, reverse polarity, blown fuse).

Loose or oxidized power interface on the module.

Internal power circuit damage (e.g., aging capacitors, faulty chips). - Communication Faults

- Symptoms: Communication Interruption between the module and controller/host computer, data transmission errors, address conflicts.

- Possible Causes:

Poor communication cable connection, damaged cables, or incorrect wiring (e.g., reversed RS-485 polarity).

Mismatched communication protocol settings (baud rate, parity, data bits).

Damaged communication chip or firmware failure in the module.

Electromagnetic interference (e.g., high-power equipment near communication lines). - Input/Output (I/O) Faults

- Symptoms: No response to input signals, abnormal output signals (e.g., relays not activating, unstable analog outputs).

- Possible Causes:

Faulty input signal sources (e.g., damaged sensors, open circuits).

Overloaded, short-circuited, or poorly connected output loads.

Loose, oxidized, or burnt I/O interface terminals.

Damaged internal I/O channels (e.g., blown transistors, worn relay contacts). - Overheating or Cooling Faults

- Symptoms: Excessive module temperature, abnormal fan operation, overheat protection triggered.

- Possible Causes:

Poor ventilation in the installation environment, dust blocking cooling vents.

Faulty module fan (stalled or low speed).

Increased power consumption due to aging internal components. - Firmware or Configuration Faults

- Symptoms: Module fails to initialize, abnormal functions, parameter loss.

- Possible Causes:

Interrupted firmware update or incorrect firmware file.

Incorrect configuration parameters (e.g., address, function mode settings).

Memory faults (e.g., EEPROM damage causing parameter loss). - Mechanical or Physical Faults

- Symptoms: Module cannot be inserted into the slot, damaged casing, loose terminals.

- Possible Causes:

Improper installation (e.g., bent slot pins due to excessive force).

Loose internal components due to vibration or impact.

Environmental corrosion (e.g., rust on metal parts from moisture or dust).

II. General Solutions

- Power Supply Troubleshooting

- Check if the external power input meets the module’s specifications (e.g., voltage range, power), and use a multimeter to measure voltage stability.

- Reconnect the power connector, clean the interface to remove oxidation, and replace the fuse (if applicable).

- If the external power is normal but the module still has no power, it may indicate an internal power fault; contact ABB technical support or replace the module.

- Communication Troubleshooting

- Inspect communication cable connections for tightness, replace cables or interface terminals, and eliminate physical connection issues.

- Ensure communication parameters (e.g., baud rate, protocol type) match the system; try restoring default configurations.

- Use serial debugging tools (e.g., Modbus Poll) to test module responses and troubleshoot protocol compatibility issues.

- If electromagnetic interference is suspected, use shielded cables, add filtering devices, or move away from interference sources.

- I/O Troubleshooting

- Input Faults: Use a multimeter to check if input signals are normal (e.g., on/off status for digital signals, voltage/current values for analog signals); replace sensors or repair circuits.

- Output Faults: Verify that the load meets the module’s rated parameters (e.g., voltage, current) to avoid overloading or short circuits; manually test outputs (e.g., force relay activation) to determine if the fault is in the module or load.

- Clean I/O terminals, re-tighten connections, and replace terminal blocks if necessary.

- Overheating Troubleshooting

- Clean dust from the module and installation environment to ensure unobstructed cooling vents.

- Check fan operation; replace the fan or inspect the fan’s power circuit if it stops rotating.

- Reduce module load or improve environmental temperature (e.g., install air conditioning or cooling fans).

- Firmware and Configuration Troubleshooting

- Refer to ABB official manuals to redownload firmware or restore factory settings via dedicated software (e.g., ABB Control Builder).

- If parameters are lost, re-enter correct configurations and save backups.

- Mechanical Fault Handling

- Ensure proper module installation to avoid damaging pins during insertion; carefully repair bent slot pins with tools or replace the slot if necessary.

- For damaged casings or loose terminals, assess the impact on electrical performance and replace the module if required.

Related Products

ABB PCD230A101 3BHE022291R0101 Excitation Controller Module

ABB 5SHX2645L0002 3BHB012961R0001 IGCT Module

ABB UNITROL1020 UNS0119A-Z,V1 3BHE030579R0001 Voltage Regulators

ABB REU615E_D HBUAEAADNCA1BNN1XD | Voltage Protection and Control

ABB REX521GHHPSH51G | Feeder Protection Relay