Description

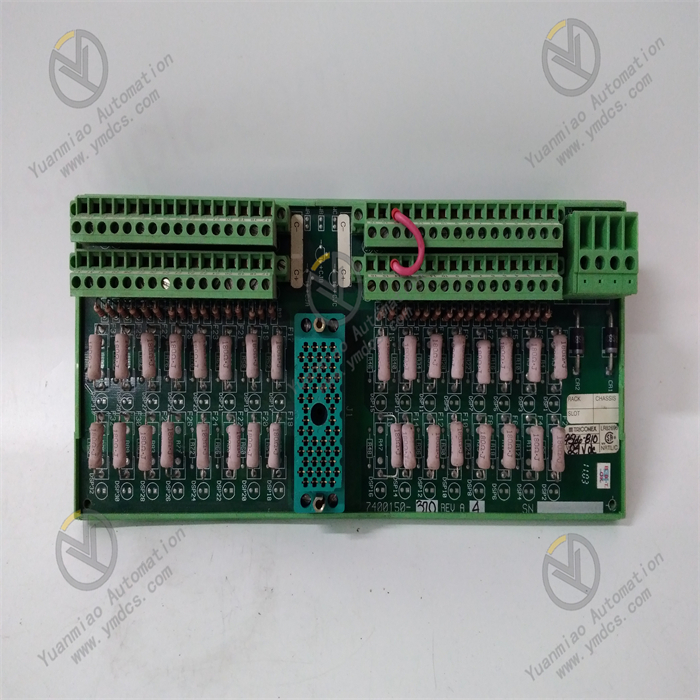

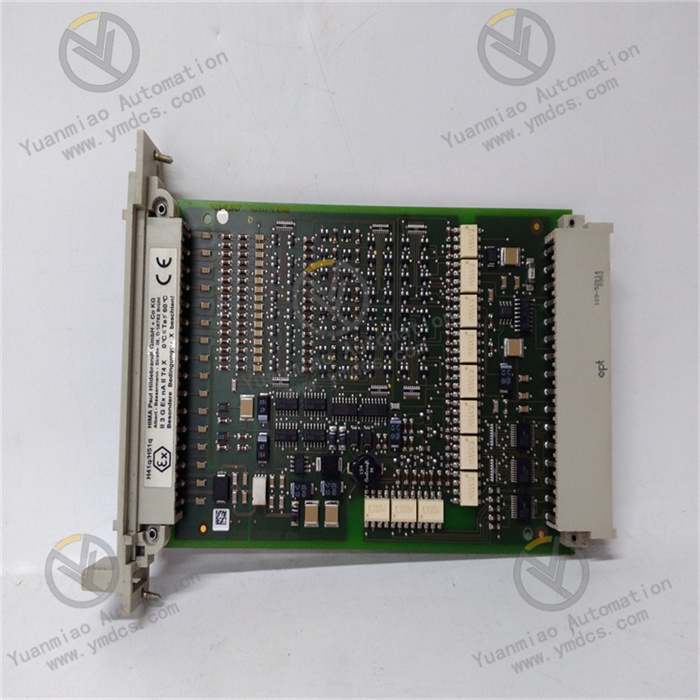

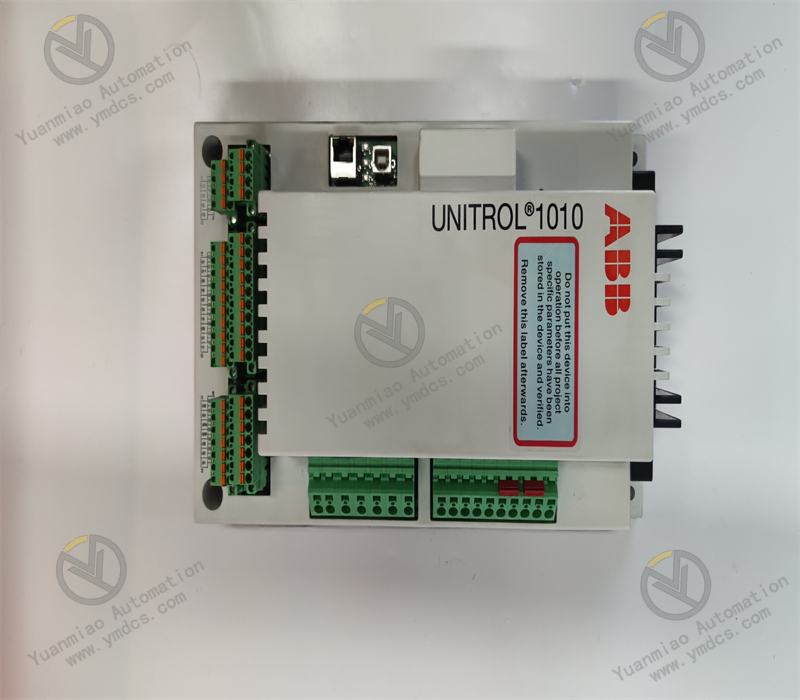

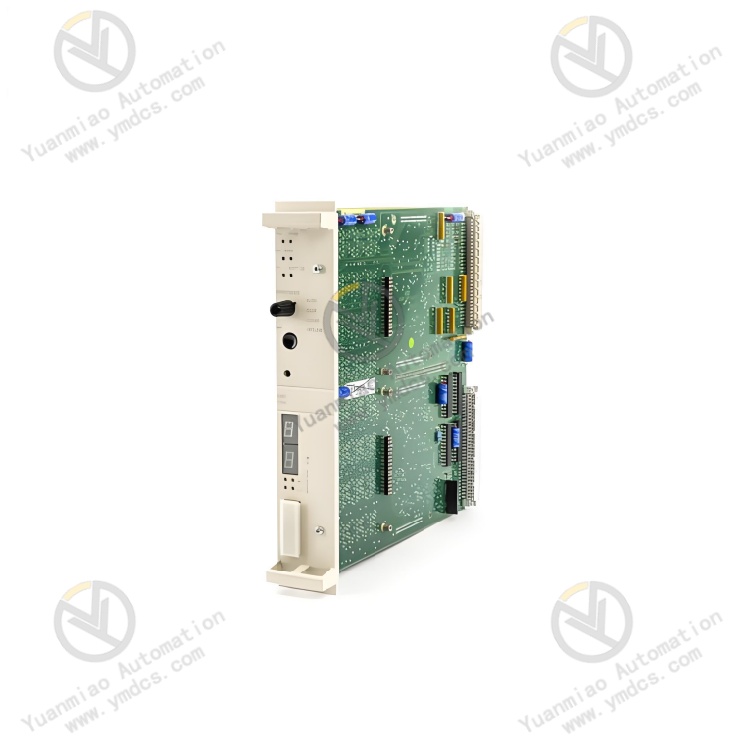

GE IS220PRTDH1A

I. Overview

The GE IS220PRTDH1A is a high-precision RTD (Resistance Temperature Detector) temperature acquisition module based on the GE Mark VIe control system architecture. It must be used in conjunction with Mark VIe controllers (e.g., IC698CPE030), standard racks (e.g., IC698CHS010), and IS220PPROH1A process control modules. Its core functions include:

- Collecting temperature signals via 16 differential RTD input channels, compatible with mainstream platinum resistance sensors such as PT100 (385Ω/℃) and PT1000 (3850Ω/℃);

- Incorporating a built-in 24-bit high-precision ADC converter to achieve accurate temperature conversion within the range of -200℃~850℃;

- Featuring RTD open/short circuit detection and lead resistance compensation (3-wire/4-wire configuration) functions;

- Supporting configuration of sampling rate and filtering parameters via the GE Mark VIe Configuration Tool;

- Transmitting temperature data to process control modules or controllers through the backplane bus to provide basic data for PID regulation.

Its core advantages lie in "dedicated RTD acquisition (16 differential channels), high-precision conversion (±0.1℃ accuracy), wide temperature adaptability (-40℃~70℃ operating temperature), and SIL 2 safety certification". It is particularly suitable for scenarios such as temperature monitoring of nuclear power equipment (e.g., nuclear island cooling systems), temperature acquisition of chemical reactors (e.g., polymerization reaction temperature), and low-temperature monitoring of pharmaceutical lyophilizers (-50℃~50℃).

The IS220PRTDH1A collects the inlet and outlet water temperatures of the condenser (PT100 sensor, measurement range 0℃~100℃) via 16 RTD channels. The lead resistance compensation function eliminates the resistance error of 100-meter wiring (compensation range 0~10Ω), maintaining the temperature acquisition accuracy at ±0.08℃. This provides accurate water temperature data for the IS220PPROH1A process control module, ensuring no deviation in the PID regulation of the cooling system and avoiding abnormal temperatures in the nuclear island (with a single failure loss exceeding RMB 10 million). In a 2000L polymerization reactor of a chemical enterprise, the module collects the reaction temperature (PT1000 sensor, measurement range 0℃~200℃), and the 24-bit ADC converter captures temperature fluctuations of 0.05℃. When the temperature deviates from the set value by ±0.5℃, the data is promptly transmitted to the control module to trigger heating/cooling adjustment, increasing the qualification rate of polymerization reactions from 97% to 99.5%. In a pharmaceutical lyophilizer, the module withstands a wide temperature range of -40℃~50℃, collects the temperature inside the lyophilization chamber (PT100 sensor, measurement range -50℃~50℃), and operates continuously for 300 days without drift, meeting the strict temperature monitoring accuracy requirements (±0.2℃) of GMP in the pharmaceutical industry.

In terms of hardware design, the module adopts a "dedicated RTD circuit + high-precision conversion" architecture:

- RTD Input Circuit: 16 differential RTD input channels, supporting 3-wire/4-wire wiring (compatible with 2-wire wiring, requiring external compensation), and adaptable to PT100 and PT1000 platinum resistors. Each channel has a built-in constant current source (1mA/2mA optional) to avoid the impact of RTD self-heating (self-heating error ≤0.01℃). It supports lead resistance compensation (0~10Ω) to eliminate resistance errors caused by long-distance wiring (maximum wiring distance 500 meters).

- High-Precision Conversion Unit: Equipped with a built-in 24-bit Σ-Δ ADC converter, the sampling rate is configurable (1Hz~100Hz), the temperature measurement range is -200℃~850℃, with an accuracy of ±0.1℃ (0℃~200℃) and ±0.2℃ (-200℃~0℃/200℃~850℃). It is equipped with a low-drift reference voltage source (drift ≤5ppm/℃) to ensure stable long-term operation accuracy.

- Housing and Protection: Adopting an industrial-grade metal housing, its dimensions comply with the 3U standard rack (19 inches), with an installation depth ≤220mm, compatible with Mark VIe standard racks. It has an IP20 protection rating, providing dust protection and protection against finger touch. The operating temperature range is -40℃~70℃, the storage temperature range is -55℃~85℃, and the relative humidity is 5%~95% (non-condensing), making it suitable for high-temperature and high-humidity environments in power plants and chemical plants.

- Safety and Diagnosis Design: It complies with the IEC 61508 SIL 2 safety certification, and key circuits (such as ADC and constant current source) adopt a dual-redundant design. It features RTD open/short circuit detection and channel overvoltage protection (±30V) functions. Fault information is transmitted to the controller through the backplane bus and can be viewed in real time via software (e.g., "Channel 3 RTD Open", "Channel 8 Overvoltage").

II. Technical Parameters

1. RTD Input and Conversion Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Input Channels | 16 differential RTD input channels, supporting 3-wire/4-wire wiring, compatible with 2-wire wiring (external resistance compensation required) |

| Compatible Sensors | PT100 (385Ω/℃, IEC 60751 Class A), PT1000 (3850Ω/℃, IEC 60751 Class A) |

| Temperature Measurement Range | -200℃~850℃, measurable sub-ranges can be divided via software (e.g., -50℃~50℃, 0℃~200℃) |

| Measurement Accuracy | 0℃~200℃: ±0.1℃; -200℃~0℃/200℃~850℃: ±0.2℃ (including sensor error) |

| ADC Resolution | 24-bit Σ-Δ ADC, effective resolution of 20 bits (corresponding to a temperature of 0.001℃) |

| Sampling Rate | Configurable 1Hz~100Hz per channel, supporting synchronous sampling between channels (synchronization deviation ≤1ms) |

| Lead Resistance Compensation | 0~10Ω (3-wire/4-wire configuration), automatically compensates for wiring resistance (maximum wiring distance 500 meters, AWG 22 wire) |

| Constant Current Source | Independent constant current source per channel, current value optional (1mA/2mA), self-heating error ≤0.01℃ |

2. Electrical and Communication Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Power Supply Requirements | Powered by the Mark VIe rack: +5V DC (±5%), maximum power consumption ≤12W; +24V DC (±10%), used for RTD excitation, maximum power consumption ≤6W |

| Isolation Method | Photoelectric isolation between input channels and backplane bus (isolation voltage ≥2.5kVrms), electrical isolation between channels (500Vrms) |

| Communication Interface | Backplane bus interface (rate 200Mbps), communicates with Mark VIe controllers/process control modules, supporting synchronous data transmission |

| Fault Output | 1 fault relay output (normally closed contact, AC250V/1A), used for module-level fault alarm |

| Overvoltage Protection | Overvoltage protection for input channels (±30V DC), short-circuit protection (maximum short-circuit current ≤50mA) |

3. Environmental and Reliability Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Operating Temperature | -40℃~70℃ (natural cooling without fans, relying on rack air ducts) |

| Storage Temperature | -55℃~85℃ |

| Relative Humidity | 5%~95% (non-condensing), complying with the IEC 60068-2-38 humidity cycle standard (2000 hours of fault-free operation) |

| Electromagnetic Interference Resistance | Emission: EN 55032 Class A; Immunity: EN 61000-6-2 (ESD ±15kV air discharge, EFT ±4kV power port, RF radiation 30V/m (80MHz~2GHz)) |

| Vibration Resistance | Complies with IEC 60068-2-6 standard: 10-500Hz, 2g acceleration (continuous operation) |

| Shock Resistance | Complies with IEC 60068-2-27 standard: 20g acceleration, 11ms pulse width (half-sine wave) |

| Mean Time Between Failures (MTBF) | ≥1,200,000 hours (Telcordia standard, 25℃ environment), channel-level MTBF ≥2,000,000 hours |

III. Functional Features

1. Dedicated High-Precision RTD Acquisition to Meet Strict Temperature Control Requirements

With "in-depth optimization of RTD signals" as its core, the IS220PRTDH1A addresses the pain points of traditional general-purpose AI modules, such as "low RTD acquisition accuracy and poor anti-interference performance":

- Wide-Range and High-Precision Measurement: The range of -200℃~850℃ covers all-scenario temperature needs, from pharmaceutical lyophilization (-50℃) to chemical reactions (200℃) and nuclear power equipment (400℃). The ±0.1℃ accuracy in the 0℃~200℃ range far exceeds that of general-purpose AI modules (±0.5℃). In a polymerization reactor, it accurately captures temperature fluctuations of 0.05℃, avoiding batch scrapping of products due to insufficient reactions (with a single loss exceeding RMB 100,000).

- Lead Resistance Compensation: The 3-wire/4-wire configuration automatically compensates for 0~10Ω wiring resistance. In a nuclear power cooling system, the resistance error of 100-meter wiring (approximately 2Ω) is fully compensated, reducing the temperature acquisition deviation from 0.3℃ to 0.08℃ and ensuring accurate PID regulation of the cooling system.

- Low Self-Heating Design: The optional 1mA/2mA constant current source ensures an RTD self-heating error ≤0.01℃, avoiding temperature measurement deviations caused by traditional high-current excitation (e.g., 5mA). In the -50℃ low-temperature measurement of a pharmaceutical lyophilizer, the impact of self-heating is negligible, meeting the GMP requirements for low-temperature accuracy (±0.2℃).

2. Multi-Channel Synchronous Acquisition for Collaborative Control of Multiple Measurement Points

In response to the need for "simultaneous monitoring of multiple measurement points" in industrial scenarios, the module ensures data consistency through synchronous sampling and channel isolation:

- Synchronous Channel Sampling: The synchronous sampling deviation of 16 channels is ≤1ms. In the monitoring of 4 temperature measurement points (top/middle/bottom/jacket) of a chemical reactor, temperatures at all points are acquired synchronously, avoiding misjudgment of temperature gradients caused by sampling time differences and helping the control module accurately adjust the jacket cooling water flow.

- Inter-Channel Isolation: The 500Vrms electrical isolation between channels prevents a fault in one channel (e.g., RTD short circuit) from affecting other channels. In a nuclear power equipment, when the RTD of Channel 6 is short-circuited, only this channel is protected, and the other 15 channels continue to collect data normally without data loss.

- Large-Capacity Data Buffer: A built-in 32MB RAM caches historical sampling data (capable of storing 1 hour of 100Hz sampling data). When communication is temporarily interrupted, the cached data is automatically uploaded after recovery, avoiding temperature data breakpoints. In a petrochemical plant, after a 3-second communication interruption, the module successfully retransmitted the temperature data during the interruption, and the control module did not malfunction.

3. Strong Anti-Interference and Wide-Temperature Design for Harsh Industrial Environments

Through hardware reinforcement and anti-interference optimization, the module ensures stable operation in complex environments:

- High Electromagnetic Interference Resistance: With 2.5kVrms input isolation and EN 61000-6-2 immunity certification, the temperature data fluctuation is ≤0.02℃ near 10kV frequency converters (electromagnetic radiation 50V/m) without false drift. In the temperature monitoring of a heating furnace in an iron and steel plant, it is not affected by the strong electromagnetic interference of the rolling mill, maintaining stable measurement accuracy.

- Wide Temperature Adaptability: The -40℃~70℃ operating temperature covers outdoor environments in northern winters (e.g., power plant cooling towers) and workshop environments in southern summers (e.g., 65℃ in chemical equipment areas). In a nuclear power project in a cold region, the module collects data normally without accuracy attenuation when starting at a low temperature of -35℃ in winter.

- Corrosion and Dust Resistance: The industrial-grade metal housing is resistant to oil pollution and mild chemical corrosion. In a sulfur-containing environment of an oil refinery, it operates continuously for 3 years without housing aging or internal circuit corrosion, ensuring long-term stable accuracy.