Description

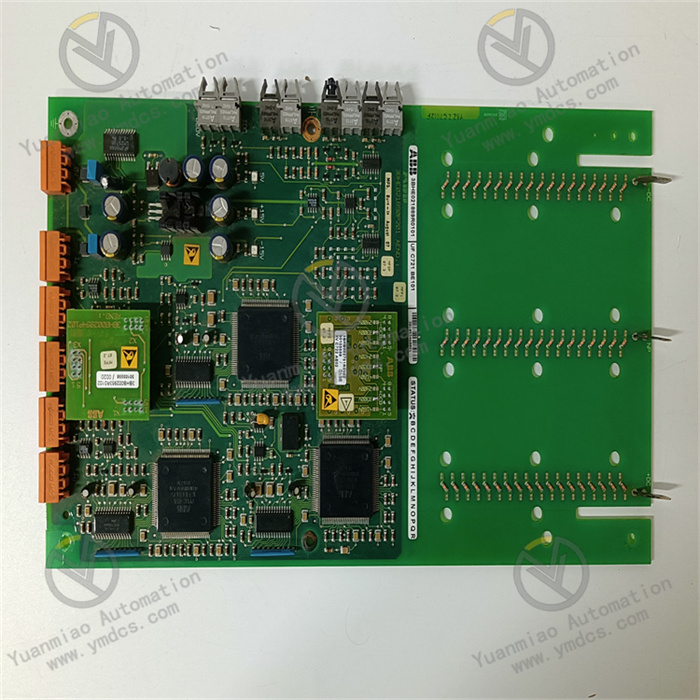

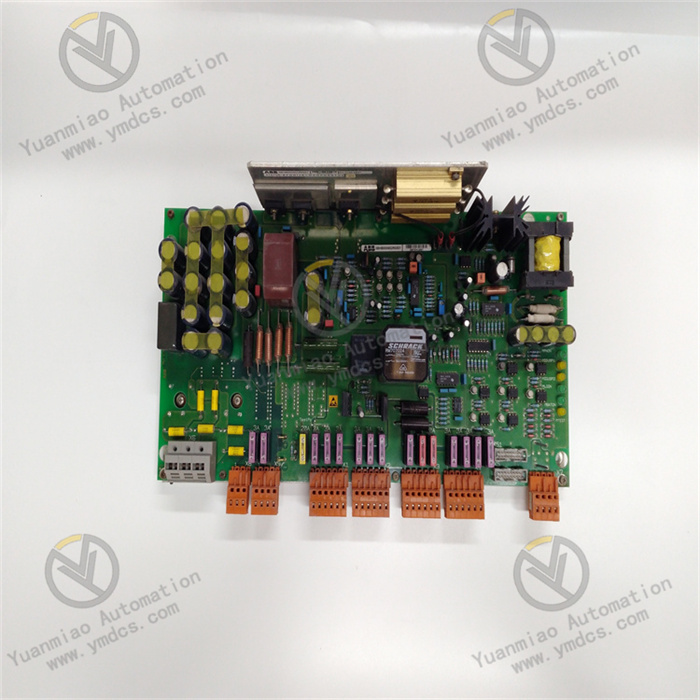

ABB PM595-4ETH-M-XC 1SAP351500R0279

Overview

The ABB PM595-4ETH-M-XC 1SAP351500R0279 is a high-performance industrial control module developed by ABB, specialized in complex automation and communication-intensive systems. As a key component of ABB's advanced control product series, this module integrates a robust hardware architecture and cutting-edge control algorithms, serving as a critical interface for multi-network communication, data processing, and system coordination in industrial applications such as power generation, smart manufacturing, and process control.

Technical Parameters

1. Power Specifications

- Input Voltage: 24V DC (±10% tolerance)

- Power Consumption: ≤25W

- Voltage Protection: Transient overvoltage suppression (TVS diodes)

2. Communication Parameters

- Ethernet Interfaces: 4 × 10/100/1000 Mbps (RJ45, supporting Modbus TCP/IP, Profinet, EtherNet/IP, OPC UA, etc.)

- Serial Ports: 3 × RS485/RS232 (Modbus RTU, ASCII protocol)

- Wireless Expansion: Optional 5G/LTE and WiFi 6 modules (via PCIe slot)

3. Processing Capability

- CPU: 64-bit ARM Cortex-A55, 2.3GHz quad-core

- Memory: 2GB RAM / 16GB Flash storage

- Data Throughput: Up to 5000 I/O operations per second

- Real-time Clock: Battery-backed (accuracy ±5ppm)

4. Environmental Specifications

- Operating Temperature: -40°C to +75°C

- Storage Temperature: -55°C to +85°C

- Humidity: 5%-95% (non-condensing)

- Vibration Resistance: 5-500Hz, 2G (IEC 60068-2-6)

- Protection Level: IP20

- Dimensions: 180mm × 120mm × 70mm

- Weight: Approximately 1.1kg

Functional Features

1. Ultra-High-Speed Multi-Network Integration

Four Gigabit Ethernet ports enable simultaneous connection to multiple industrial networks (e.g., factory intranet, cloud platforms), supporting real-time data exchange across protocols like Profinet and OPC UA for seamless OT-IT convergence.

2. Advanced Edge Computing Capability

The high-performance quad-core processor supports complex control algorithms (e.g., predictive maintenance, machine learning inference) and real-time data preprocessing, reducing reliance on central servers and minimizing network latency.

3. Industrial-Grade Redundancy Design

Built-in hardware redundancy (dual power inputs, network failover) and software fault tolerance (watchdog timer, automatic recovery) ensure 99.99% system availability. Overvoltage/overcurrent/ESD protection safeguards against transient faults in harsh environments.

4. Flexible Programming & Expansion

Supports IEC 61131-3 programming languages (Ladder Logic, Structured Text) via ABB Control Builder M. Expandable via standard I/O modules, communication cards, and AI accelerator chips to adapt to evolving Industry 4.0 requirements.

Operation Guide

1. Installation

- Mount the module on a DIN rail or control panel with power off.

- Connect 24V DC power to dual terminals (for redundancy) and ensure correct polarity.

- Use shielded CAT6/CAT7 cables for Ethernet connections; label ports for clear identification (e.g., "PROFINET 1", "Cloud Network").

2. Configuration

- Network Setup:

- Access the web interface via default IP (192.168.1.10) and configure static/dynamic IPs for each Ethernet port.

- Enable protocol-specific settings (e.g., Profinet device name, OPC UA server credentials) in ABB Control Builder M.

- Control Logic Development:

- Design control programs using IEC 61131-3 languages, integrating motor control blocks, data logging functions, and alarm triggers.

- Upload configurations to the module and verify via real-time diagnostics.

3. Commissioning

- Power on and check status LEDs:

- Steady green: Normal operation.

- Flashing red: Fault (refer to the manual for codes like E072 for network collision).

- Perform load testing by simulating 100% CPU utilization and verifying real-time data transmission within ≤5ms latency.

4. Routine Maintenance

- Monthly: Clean dust from ventilation slots using compressed air.

- Quarterly: Check power supply voltage (24V DC ±10%) and replace backup battery for the real-time clock.

- Annually: Update firmware via ABB Ability™ Platform to incorporate security patches and new features.

5. Fault Handling

- For network failures, inspect cable continuity and switch port status.

- In case of processor overload (LED blinking red), optimize control programs or add expansion modules for distributed processing.

- Contact ABB technical support with the module's diagnostic log (exportable via USB) for persistent issues.