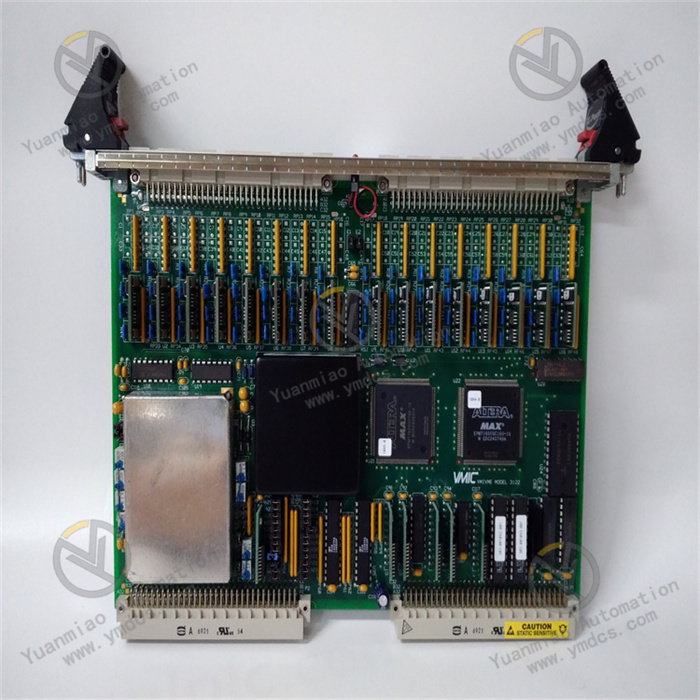

Description

ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010

The ABB 500MTM02 is a precision temperature measurement module and a key component of ABB's industrial automation control system. It is primarily used for temperature signal acquisition, processing, and control in industrial processes. Its typical application scenarios include temperature monitoring of heating/cooling systems, reactors, kilns, and other equipment in industries such as chemical, metallurgy, power, and pharmaceuticals.

Main Features

- High-Performance Processing Capability:

Equipped with an advanced processor, it efficiently executes complex control tasks and handles large-scale data exchange quickly and reliably, ensuring high precision, fast response, and efficient operation of the system. - Multi-Protocol Support:

Compatible with multiple industrial communication protocols such as Modbus, PROFIBUS, and Ethernet/IP, facilitating integration with other diverse devices and systems. - Flexible Configuration Options:

Supports various input/output configurations and setup methods to meet the diverse needs of different application scenarios, while also being easy to install and maintain. - Robust and Durable:

Compliant with industrial standards, it can operate stably in harsh environments with a working temperature range of -20°C to +70°C.

Working Principle of 500MTM02

The working principle of the 500MTM02 is based on the acquisition, conversion, and processing logic of temperature sensor signals, which can be divided into the following stages:

1. Temperature Signal Input (Front-End Acquisition)

- Supported Sensor Types:

- Thermocouples (e.g., types K, J, T, E, R, S): Utilize the thermoelectric effect of two different conductor materials to convert temperature changes into thermal electromotive force.

- RTDs (e.g., Pt100, Pt500, Pt1000, Ni100, Ni1000): Based on the temperature-dependent resistance 特性 (positive temperature coefficient) of metal conductors, temperature is calculated by measuring resistance values.

- Signal Connection Methods:

Sensor cables are connected via terminal blocks on the front end of the module, supporting 2-wire, 3-wire, or 4-wire connections (selected according to RTD type to eliminate the impact of lead resistance on measurement accuracy).

2. Signal Conditioning and Analog-to-Digital Conversion (ADC)

- Signal Amplification and Filtering:

The weak analog signals output by sensors (e.g., millivolt-level voltages from thermocouples, small resistance changes from RTDs) first pass through signal conditioning circuits, including amplification, filtering (to remove high-frequency noise), and linearization (to compensate for the nonlinear characteristics of sensors). - Analog-to-Digital Conversion:

The conditioned analog signals are converted into digital signals (e.g., 16-bit or higher-precision binary data) via an Analog-to-Digital Converter (ADC) for arithmetic processing by the microprocessor.

3. Temperature Calculation and Compensation

- Nonlinearity Correction:

The output of thermocouples and RTDs is not completely linear with temperature. The module uses built-in polynomial fitting algorithms or look-up table methods to linearize raw data and improve measurement accuracy. - Cold Junction Compensation (for Thermocouples):

The thermoelectromotive force of thermocouples is related to the cold junction (reference junction) temperature. The module monitors its own temperature through an internal temperature sensor and uses software algorithms to implement cold junction temperature compensation, ensuring that measured values reflect the true temperature of the object being measured. - Open Circuit Detection:

Continuously monitors the continuity of the sensor circuit. If a disconnected cable or poor contact is detected, it immediately outputs a fault signal (e.g., alarm code or status bit).

4. Data Processing and Output

- Signal Conversion and Standardization:

Processed temperature data can be output in the following ways: - Analog Output: Converted into standard industrial signals (e.g., 4-20mA, 0-10V) for acquisition by other control devices (such as PLCs and DCS systems).

- Digital Communication: Data interaction with upper computers or control systems via bus protocols (e.g., Modbus RTU, PROFINET, EtherCAT).

- Control Logic (if supported):

Some models of the 500MTM02 have built-in simple control functions (such as PID regulation), which can directly output control signals (such as relay contacts, pulse signals) based on set temperature thresholds to drive actuators (such as heaters and cooling valves).

5. Power Supply and Anti-Interference Design

- Power Supply Method:

Typically powered by DC (e.g., 24V DC), with some models supporting wide voltage input (e.g., 10-30V DC) to ensure stable operation in industrial environments. - Anti-Interference Measures:

- Hardware Level: Isolation circuits, shielding designs, and filter capacitors are used to suppress electromagnetic interference (EMI) and radio frequency interference (RFI).

- Software Level: Digital filtering algorithms (such as average filtering and median filtering) are used to further reduce signal noise.

Key Technical Characteristics

| Characteristic | Description |

|---|---|

| Measurement Accuracy | Typically ±0.1% FS (full scale) or higher, depending on sensor type and module configuration. |

| Resolution | Up to 0.1°C or 0.01°C, meeting high-precision measurement requirements. |

| Response Time | Typical value of 50-200ms, supporting fast tracking of dynamic temperature changes. |

| Operating Temperature Range | -40°C to +85°C (industrial grade), adapting to harsh environments. |

| Redundancy and Diagnosis | Supports channel redundancy configuration and built-in self-diagnosis functions (e.g., sensor fault, power abnormality, communication interruption alarms). |

Application Fields

- Process Control: Used for automation control in industries such as chemical and oil & gas to achieve precise monitoring and control of various parameters in production processes.

- Manufacturing: Suitable for automation control in production lines, such as automotive manufacturing and electronic device production, to ensure process stability and consistency.

- Energy Management: Plays a role in power system monitoring and control, helping to optimize the management of power generation, transmission, and distribution.

- Building Management: Applied to data exchange in building automation systems to achieve centralized control of equipment such as lighting, air conditioning, and elevators in buildings.