Description

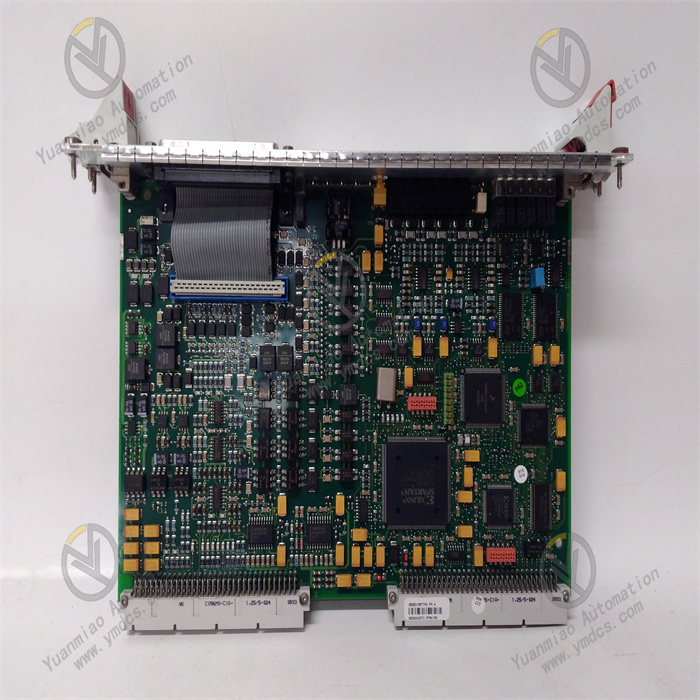

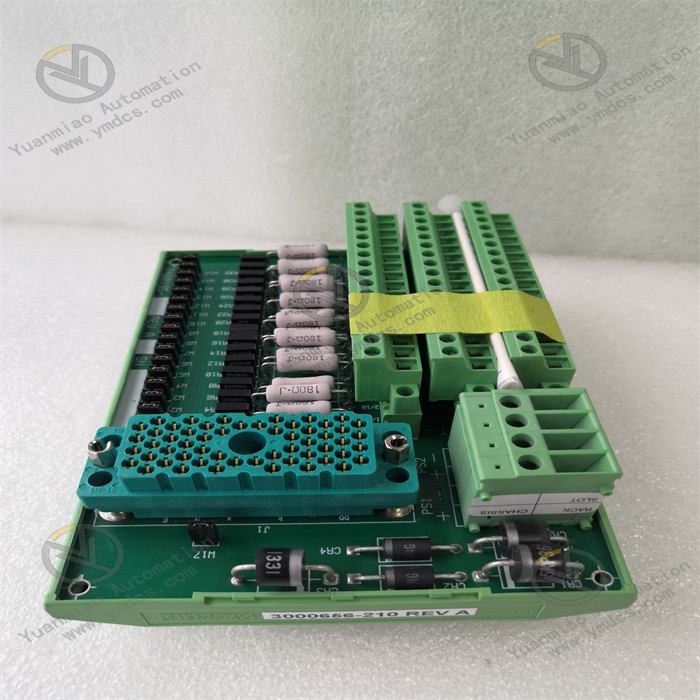

ABB CI526V1 3BSE012870R1

I. Functional Features

Multi-Protocol Communication Capability

- Supports mainstream protocols such as Industrial Ethernet (EtherNet/IP, Modbus TCP), Profibus DP, and CANopen, enabling seamless integration with cross-vendor devices like PLCs, sensors, and drives to achieve cross-system data interaction.

- Supports master/slave mode, adapting to complex industrial network topologies (e.g., ring, star) to meet large-scale system expansion needs.

High Reliability and Real-time Design

- Hardware Redundancy Technology: Integrates communication link redundancy (e.g., dual network port hot backup) and power supply backup. It switches to the standby link within milliseconds (≤5ms) in case of main link failure, ensuring zero downtime in continuous production scenarios such as power and chemical industries.

- High-speed Data Processing: Equipped with a high-performance processor, supporting real-time control algorithms and high-speed data collection. The communication cycle is ≤1ms, suitable for harsh scenarios requiring equipment status monitoring and motion control.

Flexible Expansion and Convenient Maintenance

- Hot-swappable Function: Enables online module replacement, allowing hardware upgrades without shutdown to reduce production downtime.

- Modular Expansion: Connects up to 8 I/O modules (discrete, analog, special function modules) via expansion bases. The maximum number of I/O points is flexibly adjusted according to configurations, adapting to small single machines and large production lines.

Intelligent Diagnosis and Remote Management

- Self-diagnosis Mechanism: Monitors module temperature, voltage, and communication quality in real time, quickly locating faults through LED indicators (power, communication, fault) and system alarms.

- Remote Configuration: Supports remote monitoring of operating status via ABB programming software (e.g., AC 800M) or third-party tools, simplifying on-site maintenance.

II. Technical Parameters

| Parameter Type | Specific Indicators |

|---|---|

| Communication Interfaces | - Industrial Ethernet (10/100Mbps, EtherNet/IP, Modbus TCP) - Profibus DP (up to 12Mbps) - CANopen (DS301/DS401 protocols) - Supports fiber/cable media |

| Power Supply | - 24V DC (±10%) - Power consumption: ~10W (typical) |

| I/O Expansion Capability | - Up to 8 expansion bases, supporting discrete, analog, temperature input, etc., modules - Maximum I/O points: dynamically configurable |

| Processing Speed | - Communication cycle ≤1ms (high-speed mode) - Ethernet: 100Mbps, Profibus: up to 12Mbps |

| Operating Environment | - Temperature: -20°C ~ +60°C (non-condensing) - Humidity: 5% ~ 95% (non-condensing) - Protection class: IP20 (panel mounting) |

| Physical Dimensions | ~100mm×200mm×60mm, compact design for standard control cabinets |

III. Application Fields

Manufacturing Automation

- Automobile Production Lines: Connects welding robots, conveyors, and PLCs via EtherNet/IP to achieve multi-station collaborative control, improving production cycle precision.

- Electronic Equipment Manufacturing: Collects data from chip mounters and testing devices via Profibus DP, supporting automated production line scheduling and quality traceability.

Power and Energy Systems

- Substation Automation: Docks with relay protection devices and smart meters via Modbus TCP for status monitoring and fault warning.

- New Energy Control: Connects inverters and pitch systems via CANopen in photovoltaic/wind power systems to optimize energy conversion efficiency.

Process Control Industry

- Chemical & Petroleum: Collects temperature, pressure, etc., via Profibus DP, achieving closed-loop control (e.g., PID adjustment) for distillation columns and reactors with redundant links.

- Metallurgy: Applied to blast furnace batching and rolling mill speed control to ensure stable process parameters.

Intelligent Building & Logistics

- Building Automation: Integrates HVAC and water supply/drainage systems via Modbus TCP for energy management.

- Logistics & Warehousing: Docks with conveyors and sorting robots, achieving real-time multi-device scheduling via EtherNet/IP.

IV. Comparative Advantages over Similar Products

- Protocol Compatibility: Supports parallel multi-protocol processing without extra gateways, reducing integration costs (traditional solutions require 2-3 gateways, while CI526V1 adapts directly).

- Redundancy Performance: Hardware-level redundancy (dual network port hot backup) responds faster than software fault tolerance (fault switching <5ms), suitable for critical scenarios like pharmaceuticals and food production.

- Expansion Flexibility: Modular "plug-and-play" design allows on-demand I/O module expansion, avoiding initial investment waste.

- Real-time Optimization: Communication cycle ≤1ms meets response-sensitive scenarios such as wafer handling in semiconductor equipment and high-speed sorting.

V. Typical Application Scenarios

- Automobile Painting Lines: Connects painting robots, drying furnace controllers, and PLCs via EtherNet/IP, synchronizing trajectory parameters and furnace temperature in real time. Redundant links ensure uninterrupted communication, improving paint yield.

- Sewage Treatment Monitoring Systems: Collects water quality sensor data (pH, turbidity) and pump status via Profibus DP, uploading to SCADA via Modbus TCP for automated adjustment and remote monitoring.