Description

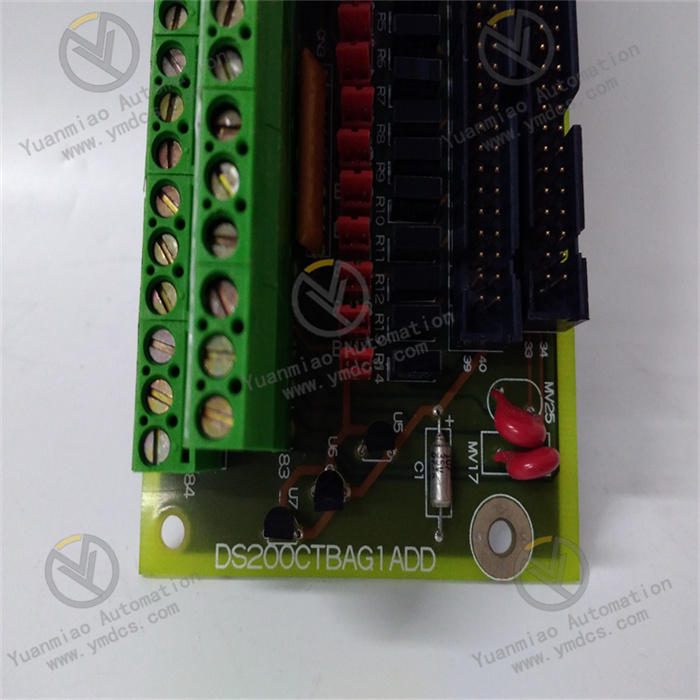

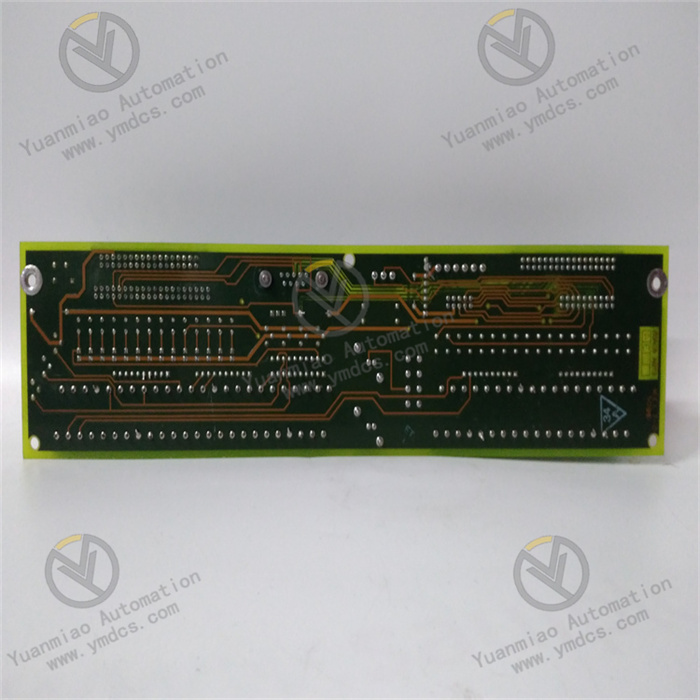

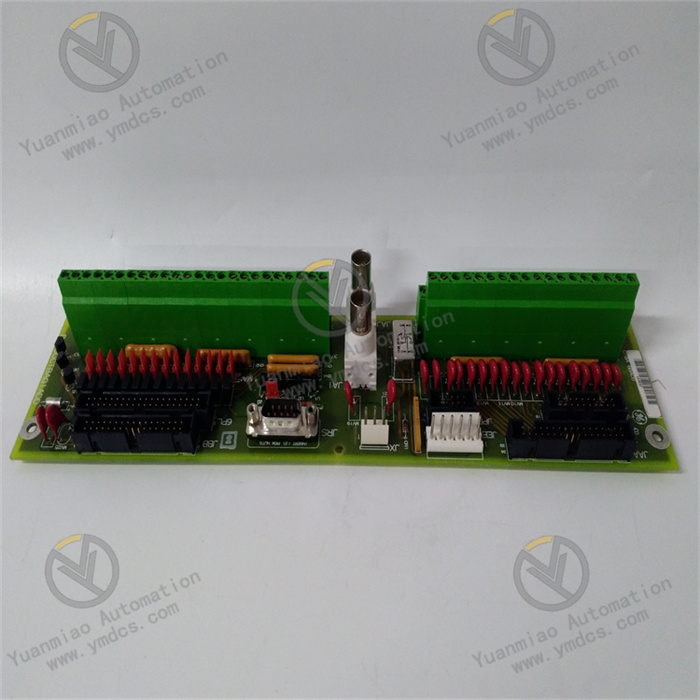

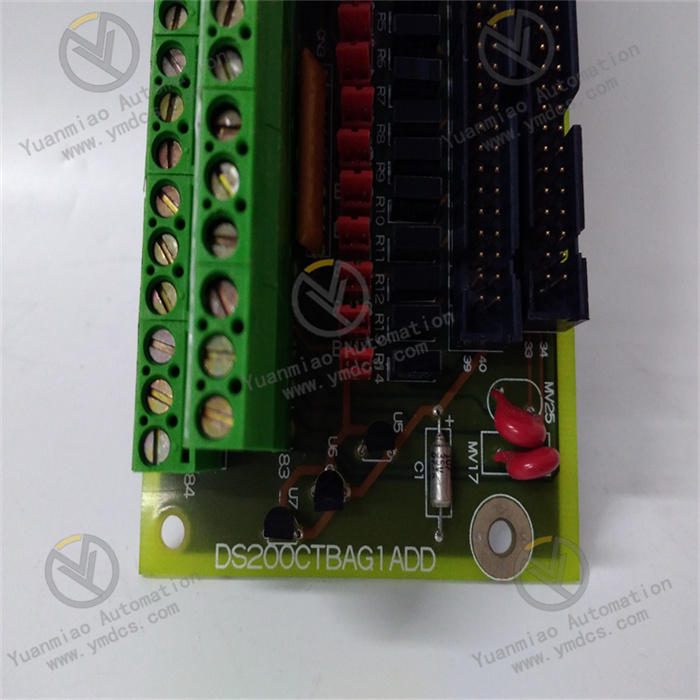

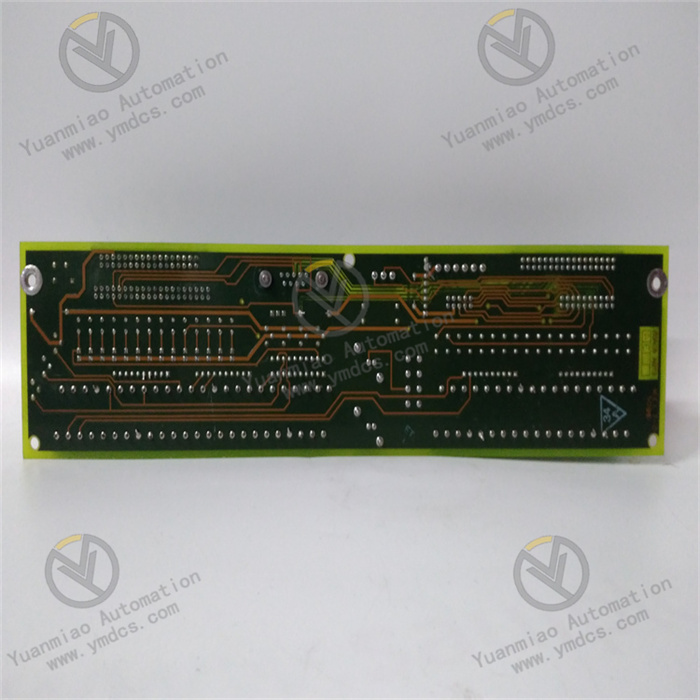

GE DS200CTBAG1ADD

The GE DS200CTBAG1ADD is a high-performance industrial control module developed by General Electric (GE), designed for complex automation and drive systems. As a key component of GE's classic DS200 series, this module integrates advanced control algorithms and a robust hardware architecture, serving as a critical interface for signal processing and system coordination in industrial applications such as power generation, manufacturing, and process control.

- Input Voltage: 24V DC (±10% tolerance)

- Output Voltage: 0-10V DC (analog) / 24V DC (digital)

- Power Consumption: ≤15W

- I/O Channels: 8 analog inputs / 16 digital I/O channels

- Communication Interfaces: RS485 (Modbus RTU), Ethernet (Modbus TCP/IP), CANopen

- Frequency Response: 0-20kHz

- Control Accuracy: Speed: ±0.1% / Torque: ±2%

- Operating Temperature: -40°C to +70°C

- Storage Temperature: -55°C to +85°C

- Humidity: 5%-95% (non-condensing)

- Protection Level: IP20

- Dimensions: 140mm × 100mm × 45mm

- Weight: Approximately 0.9kg

Supports simultaneous acquisition and processing of analog and digital signals, enabling real-time monitoring of parameters like voltage, current, and temperature in industrial systems.

Compatible with industry-standard protocols (Modbus, CANopen, etc.), allowing seamless integration with PLCs, SCADA systems, and HMIs for remote configuration and real-time data exchange.

Built-in overvoltage, overcurrent, and ESD protection safeguards against transient faults. Opto-isolated I/O channels prevent ground loops and electromagnetic interference, enhancing system reliability.

Enables module replacement without system shutdown, minimizing downtime. The standardized structure supports easy expansion of I/O capacity to meet evolving production needs.

- Mount the module on a DIN rail or control panel with power off.

- Connect 24V DC power supply to the designated terminals, ensuring correct polarity.

- Wire analog/digital I/O signals using shielded cables to minimize interference.

- Use GE's dedicated software (e.g., Proficy Machine Edition) to set parameters via RS485 or Ethernet.

- Configure I/O mapping, communication protocols, and signal scaling based on application requirements.

- Power on the system and check the status LED: green for normal operation, red for fault.

- Perform signal loop testing to verify analog input/output accuracy and digital I/O responsiveness.

- Regularly clean the module's heat sink to prevent dust accumulation.

- Monitor input voltage stability and check for loose terminal connections.

- Update firmware periodically via GE's official platform to ensure optimal performance.

- Refer to the module's front-panel LED fault codes (e.g., E003 for overvoltage) and follow troubleshooting steps in the manual.

- Contact GE technical support with fault logs for persistent issues.

![]()