Description

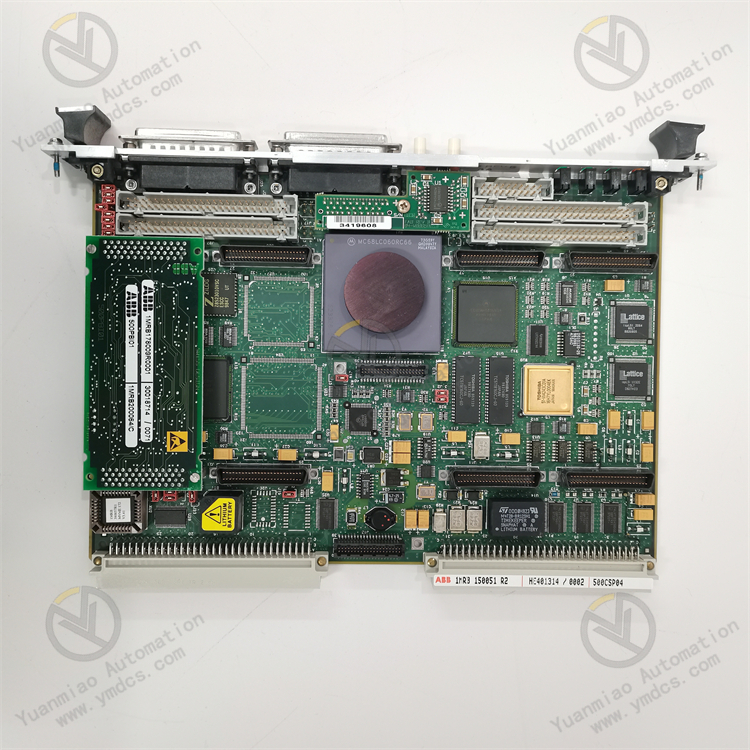

ABB 81AB03-E GJR2392500R1210

I. Basic Information

- Full Model: 81AB03-E GJR2392500R1210

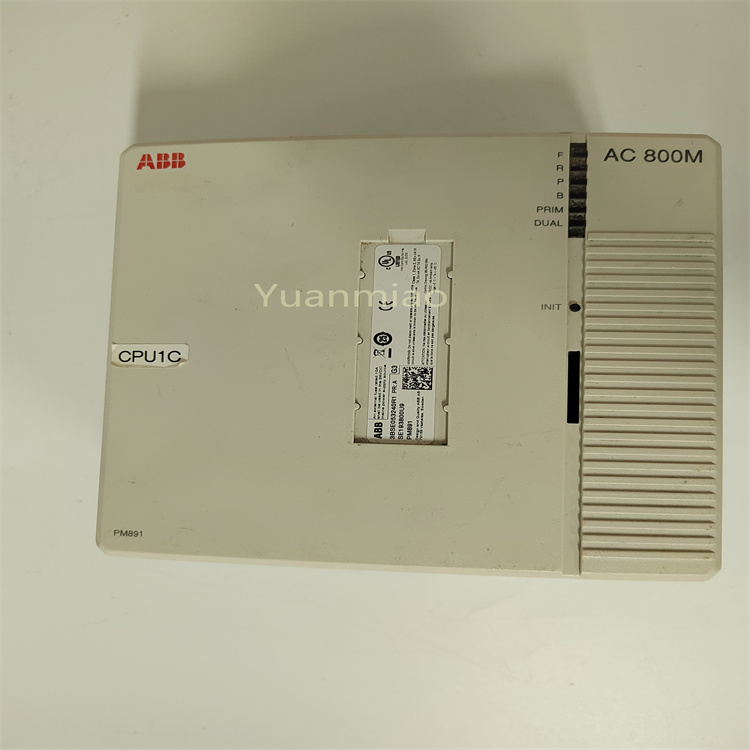

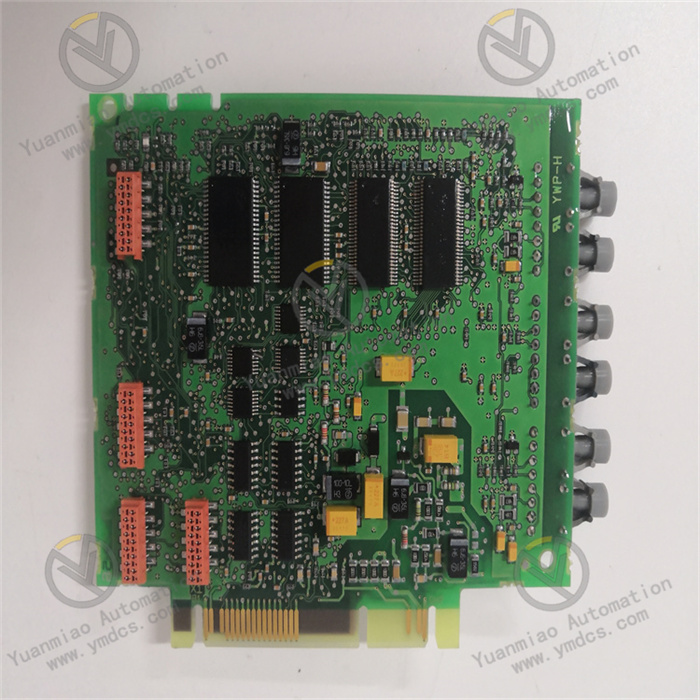

- Series: ABB industrial automation control module, commonly used in AC 800M control systems or Bailey INFI 90 systems. It belongs to the analog input/output (I/O) module.

- Purpose: As a signal acquisition and control execution unit in industrial automation systems, it connects field analog sensors (e.g., temperature/pressure transmitters) or actuators (e.g., control valves) to achieve data collection and control signal output. It is suitable for scenarios requiring precise analog signal processing in power, chemical, energy, etc.

II. Core Functions and Features

Signal Processing Capability

- Input/Output Types:

- Supports multi-channel analog input (AI) and analog output (AO), typically configured as 8 AI channels or 4 AO channels. It is compatible with signal types such as current (4-20mA), voltage (0-10V), resistance temperature detector (RTD), and thermocouple (TC).

- Supports preprocessing functions such as signal linearization, filtering, and range conversion (e.g., engineering unit conversion).

- Accuracy and Resolution:

- Analog-to-digital conversion (ADC) resolution ≥16 bits, digital-to-analog conversion (DAC) resolution ≥14 bits, ensuring high-precision signal acquisition and output (error ≤±0.1% FS).

Interfaces and Electrical Characteristics

- Physical Interfaces: Interconnects with controllers (e.g., PM866A) via backplane bus. External wiring uses detachable terminal blocks and supports shielded cable connections for anti-interference.

- Electrical Isolation: Electrical isolation between channels and between the module and system (isolation voltage ≥500V AC) prevents field interference from affecting system stability.

Diagnosis and Reliability

- Self-Diagnosis Function: Monitors channel faults (e.g., open circuit, out-of-range), power anomalies, etc. in real time, alarms via LED indicators on the module (e.g., ERROR, CHANNEL FAULT), and generates system logs.

- Hot-Swap Support: Enables online module replacement without shutdown, reducing industrial system maintenance time.

III. Technical Parameters

| Parameter Dimension | Specific Indicators |

|---|---|

| Signal Types | AI: 4-20mA, 0-10V, RTD (PT100/PT1000), TC (Type K/J/T, etc.); AO: 4-20mA/0-10V |

| Number of Channels | 8 AI or 4 AO channels (depending on specific configuration) |

| Sampling Rate | Single-channel sampling rate ≥100Hz, supporting multi-channel synchronous sampling |

| Operating Voltage | DC 24V (±10%), power consumption ≤8W |

| Operating Temperature | -20℃~+60℃, humidity 5%~95% (non-condensing) |

| Protection Level | IP20 (indoor installation), compliant with EN 61131-2 industrial standard |

IV. Application Scenarios

Power Industry

- Temperature and pressure signal acquisition for generator sets, applied to turbine control (DEH) systems or boiler monitoring (FSSS).

- Analog monitoring of transformer oil temperature, bus voltage, etc., in substations, connected to SCADA systems for remote monitoring.

Process Industry

- Acquisition of temperature, pressure, and flow signals in chemical reactors; control valve opening via AO output to achieve closed-loop control (e.g., PID regulation).

- Real-time monitoring and control of liquid level and component concentration in distillation columns of petroleum refining units.

Energy and Environmental Protection

- Analog acquisition of water pump head and sewage flow in wastewater treatment plants; control of aeration valve opening to adjust dissolved oxygen (DO) concentration.

- Monitoring of inverter output voltage and current in photovoltaic power stations, connected to energy management systems .