Description

ABB PM5630-2ETH 1SAP131000R0278

The ABB PM5630-2ETH 1SAP131000R0278 is a high-performance industrial control module developed by ABB, specialized in complex automation and communication systems. As a key component of ABB's advanced control product series, this module integrates robust hardware architecture and advanced control algorithms, serving as a critical interface for system communication, data processing, and functional coordination in industrial applications such as power generation, manufacturing, and process control.

- Input Voltage: 24V DC (±10% tolerance)

- Power Consumption: ≤18W

- Voltage Protection: Transient overvoltage suppression (TVS diodes)

- Ethernet Interfaces: 2 × 10/100/1000 Mbps (RJ45, supporting Modbus TCP/IP, Profinet, EtherNet/IP, etc.)

- Serial Ports: 2 × RS485/RS232 (Modbus RTU, ASCII protocol)

- Expansion Slots: 1 × PCIe for optional wireless modules (WiFi/4G)

- CPU: 32-bit ARM Cortex-A7, 1.4GHz

- Memory: 512MB RAM / 4GB Flash

- Data Processing Rate: Up to 1500 I/O operations per second

- Operating Temperature: -30°C to +70°C

- Storage Temperature: -40°C to +85°C

- Humidity: 5%-95% (non-condensing)

- Protection Level: IP20

- Dimensions: 130mm × 100mm × 55mm

- Weight: Approximately 0.7kg

Dual Gigabit Ethernet ports enable real-time data exchange with PLCs, SCADA systems, and HMIs, supporting multiple industrial protocols for seamless integration into complex automation networks.

The high-performance ARM processor supports real-time monitoring of industrial parameters, advanced logic control, and fault diagnosis, ensuring stable system operation under variable loads.

Built-in overvoltage, overcurrent, and ESD protection safeguards against transient faults. The module withstands harsh environments with high electromagnetic interference and temperature fluctuations.

Standardized architecture allows easy integration with additional I/O modules or communication interfaces, adapting to evolving production requirements.

- Mount the module on a DIN rail or control panel with power off.

- Connect 24V DC power supply to the designated terminals, ensuring correct polarity.

- Wire Ethernet/serial cables using shielded connectors to minimize interference.

- Use ABB's dedicated software (e.g., Control Builder M) to set parameters via Ethernet:

- Configure IP addresses, communication protocols, and data mapping based on application needs.

- Define control logic and I/O mapping for specific industrial scenarios.

- Power on the system and check status LEDs: green for normal operation, red for fault.

- Test network connectivity and perform data transmission tests to verify communication stability.

- Regularly clean the module to prevent dust accumulation.

- Monitor power supply voltage and check for loose connections in terminals.

- Update firmware periodically via ABB's official platform to ensure optimal performance.

- Refer to front-panel LED fault codes and follow troubleshooting steps in the manual.

- Contact ABB technical support with fault logs for persistent issues.

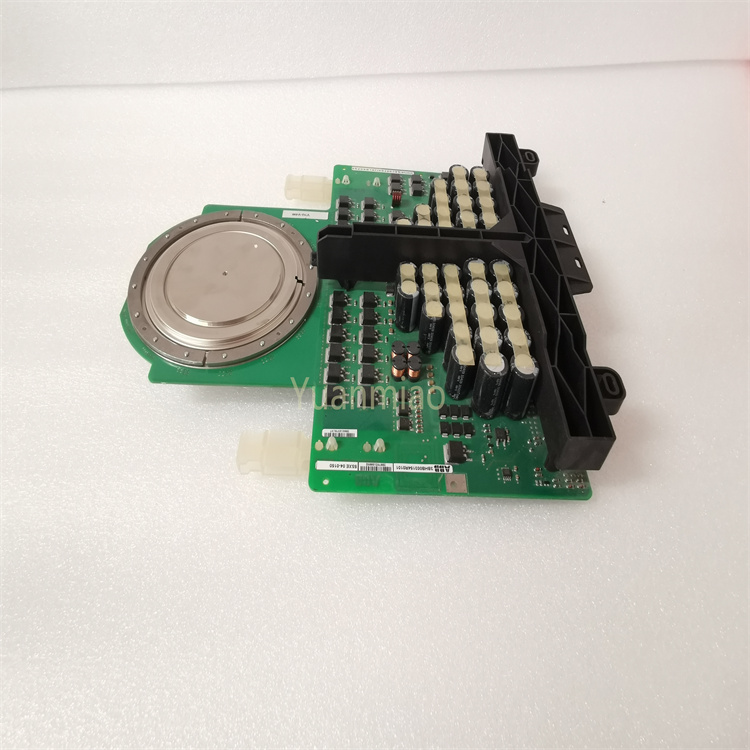

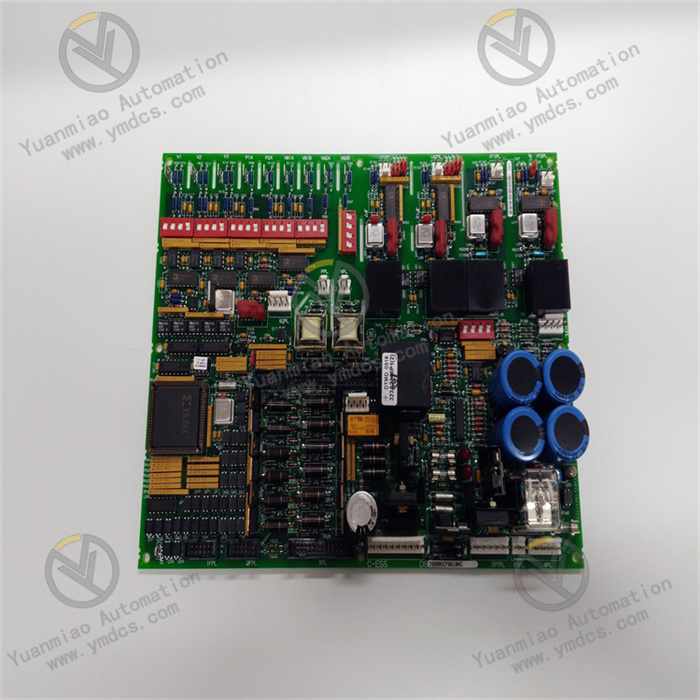

![]()