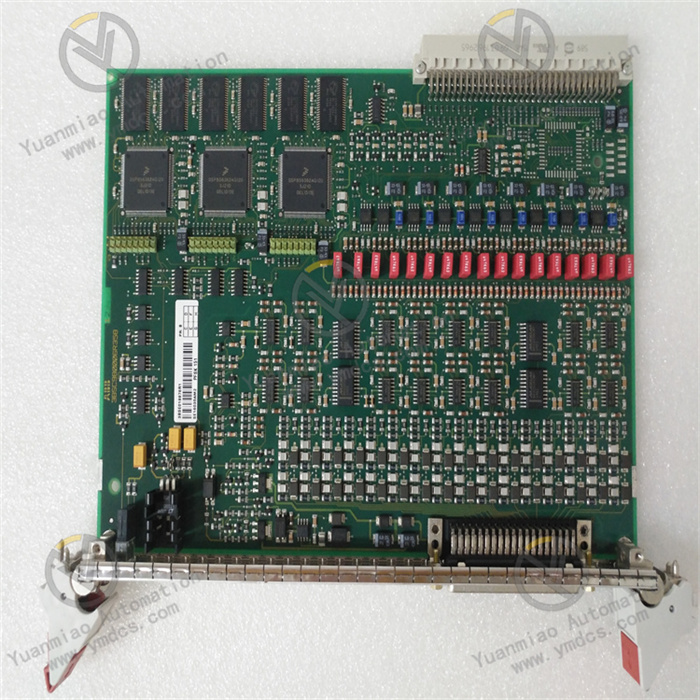

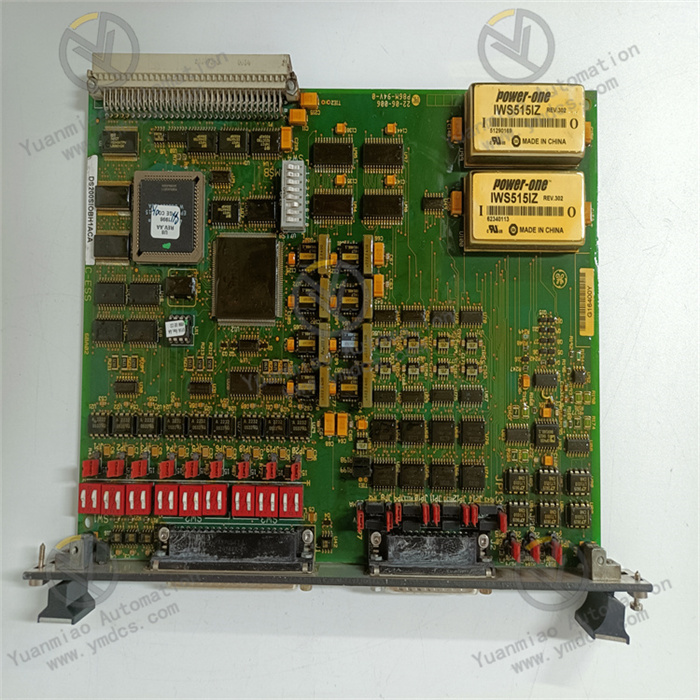

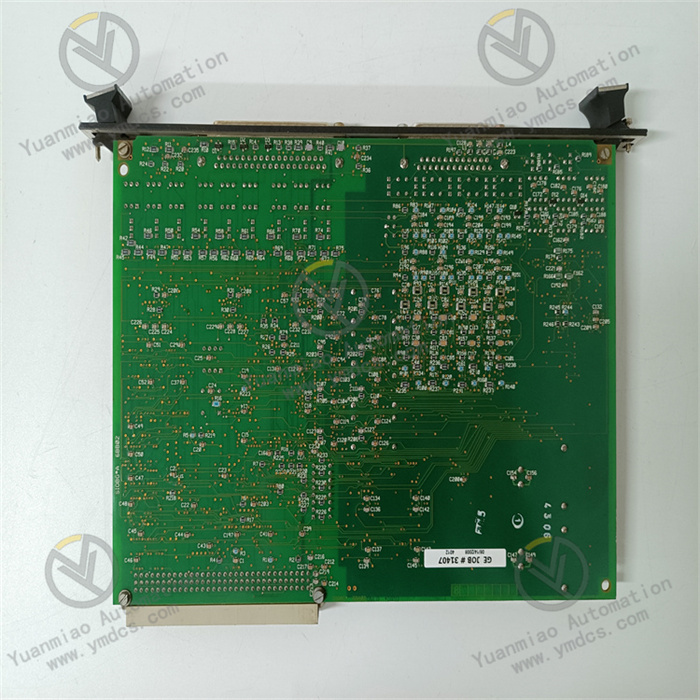

Description

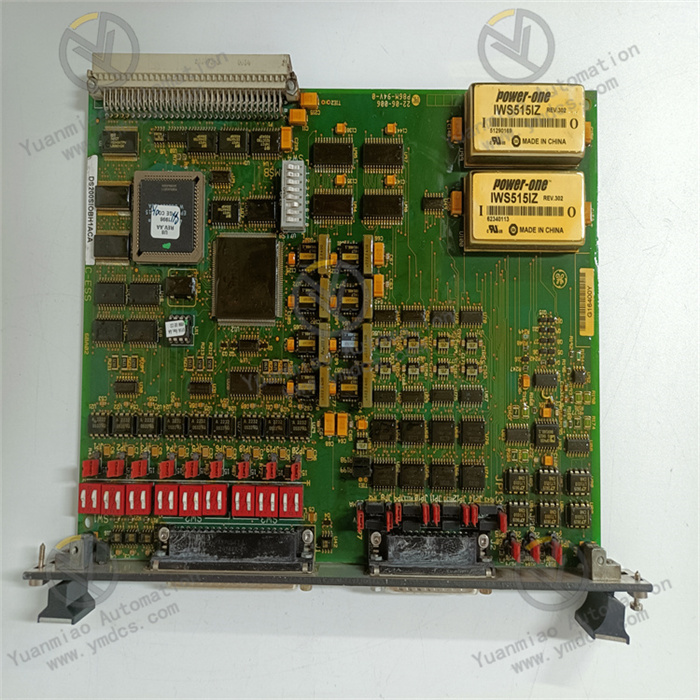

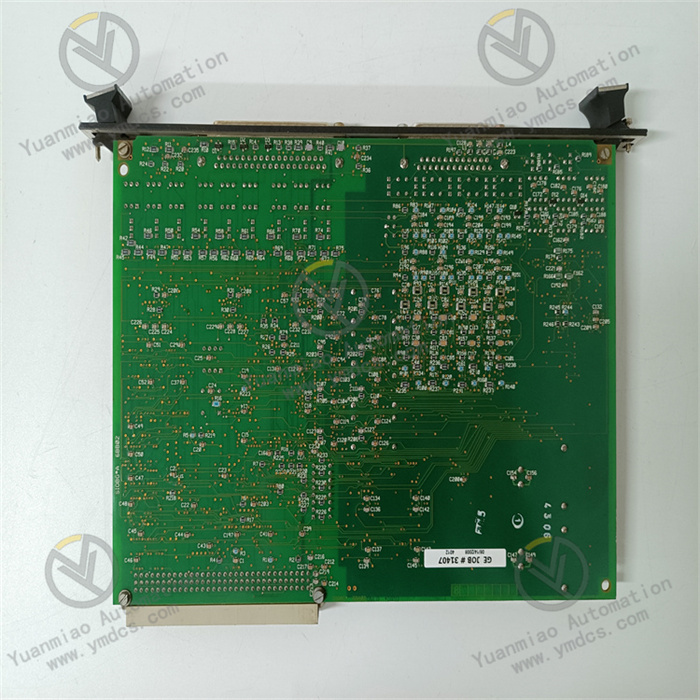

GE DS200SIOBH1ACA

The GE DS200SIOBH1ACA is a high-performance industrial control module developed by General Electric (GE), designed for complex automation systems. As a key component of GE's DS200 series, this module integrates reliable hardware architecture and advanced control algorithms, serving as an interface for signal input/output (I/O) and system coordination in industrial applications such as power generation, manufacturing, and process control.

It enables real-time processing of analog and digital signals, supporting seamless communication between field devices and upper-level control systems. The module's robust design ensures stable operation in harsh environments with high humidity, temperature fluctuations, or electromagnetic interference.

- Input Voltage: 24V DC (±10% tolerance)

- Power Consumption: ≤15W

- Voltage Protection: Transient overvoltage suppression (TVS diodes)

- Analog Inputs: 8 channels (0-10V DC / 4-20mA)

- Analog Outputs: 4 channels (0-10V DC / 4-20mA)

- Digital I/O: 16 channels (24V DC, opto-isolated)

- Resolution: 12-bit (analog), 16-bit (digital)

- RS485 (Modbus RTU)

- Ethernet (Modbus TCP/IP)

- CANopen (optional)

- Operating Temperature: -40°C to +70°C

- Storage Temperature: -55°C to +85°C

- Humidity: 5%-95% (non-condensing)

- Protection Level: IP20

- Dimensions: 140mm × 100mm × 45mm

- Weight: Approximately 0.9kg

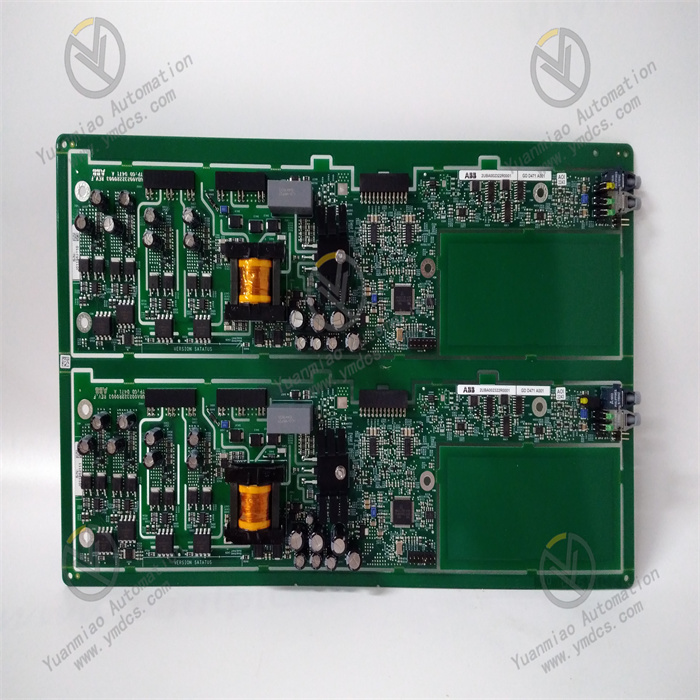

Supports simultaneous acquisition and processing of analog and digital signals, enabling real-time monitoring of parameters like voltage, current, and temperature. It converts field signals into standardized outputs for control systems.

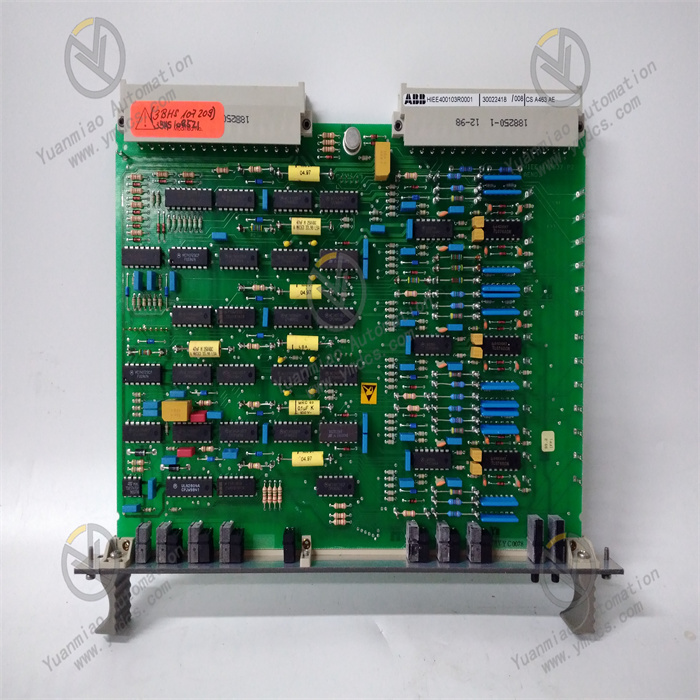

Compatible with industry-standard protocols (Modbus, CANopen), allowing seamless integration with PLCs, SCADA systems, and HMIs. It facilitates remote configuration and data logging for efficient system management.

Built-in overvoltage, overcurrent, and ESD protection safeguards against transient faults. Opto-isolated I/O channels prevent ground loops and electromagnetic interference, enhancing system reliability.

Enables module replacement without powering down the system, minimizing downtime. The standardized structure supports easy expansion of I/O capacity to meet evolving production needs.

- Cause: Power supply failure / fuse blown

- Solution: Check 24V DC connection; replace fuse (2A slow-blow) on the terminal block.

- Cause: Wiring interference / calibration drift

- Solution: Shield signal cables; perform hardware calibration via the configuration software.

- Cause: Overvoltage damage / contact oxidation

- Solution: Inspect voltage ratings of connected devices; clean terminal contacts with isopropyl alcohol.

- Cause: Cable damage / protocol mismatch

- Solution: Test communication cables with a multimeter; verify baud rate (default: 9600 bps) and data format (8N1).

- Cause: Dust accumulation / insufficient ventilation

- Solution: Clean the module's heat sink; ensure the control cabinet fan operates at ≥20CFM.

![]()