Description

Technical Parameters

Processor: Typically equipped with a high-performance 32-bit RISC processor running at 2.13 GHz, capable of rapidly processing complex control algorithms and large volumes of real-time data.

Memory: Generally includes 64MB of RAM and 64MB of Flash for program and data storage. Some specifications also indicate 4MB Flash PROM (firmware storage) and 64MB of SDRAM.

Communication Interfaces: Supports multiple communication ports such as Ethernet, RS-485, and RS-232, enabling easy data interaction and system integration with other devices.

Power Supply: Operates at 24V DC, with a typical power consumption of approximately 5.1W and a maximum of 8.6W (including full power supply to module buses and CEX buses). The typical current consumption is 210mA (maximum 360mA, excluding bus power supply).

Dimensions and Weight: Measures approximately 13.5cm×11.9cm×18.6cm, with a shipping weight of about 4kg.

Operating Environment: Functions in a temperature range of -40°C to +70°C (operating) and -40°C to +85°C (storage), adapting to harsh industrial environments.

Memory: Generally includes 64MB of RAM and 64MB of Flash for program and data storage. Some specifications also indicate 4MB Flash PROM (firmware storage) and 64MB of SDRAM.

Communication Interfaces: Supports multiple communication ports such as Ethernet, RS-485, and RS-232, enabling easy data interaction and system integration with other devices.

Power Supply: Operates at 24V DC, with a typical power consumption of approximately 5.1W and a maximum of 8.6W (including full power supply to module buses and CEX buses). The typical current consumption is 210mA (maximum 360mA, excluding bus power supply).

Dimensions and Weight: Measures approximately 13.5cm×11.9cm×18.6cm, with a shipping weight of about 4kg.

Operating Environment: Functions in a temperature range of -40°C to +70°C (operating) and -40°C to +85°C (storage), adapting to harsh industrial environments.

Key Features

High Performance: Utilizes a high-performance processor to handle large datasets in real time, ensuring rapid system response and meeting control requirements in complex industrial applications.

High Reliability: Industrial-grade design with high reliability, supporting redundant configurations to ensure system continuity during faults. Suitable for long-term stable operation in harsh industrial environments.

Multifunctionality: Supports multiple communication protocols and interfaces (e.g., Ethernet, PROFIBUS, MODBUS), facilitating interconnection with other devices and adapting to a wide range of industrial applications.

Openness: Features good openness for easy integration with devices or systems from other brands, enabling convenient system expansion and upgrades.

Security: Complies with relevant safety standards and incorporates multiple security functions (e.g., data encryption, access control) to ensure secure and stable system operation.

High Reliability: Industrial-grade design with high reliability, supporting redundant configurations to ensure system continuity during faults. Suitable for long-term stable operation in harsh industrial environments.

Multifunctionality: Supports multiple communication protocols and interfaces (e.g., Ethernet, PROFIBUS, MODBUS), facilitating interconnection with other devices and adapting to a wide range of industrial applications.

Openness: Features good openness for easy integration with devices or systems from other brands, enabling convenient system expansion and upgrades.

Security: Complies with relevant safety standards and incorporates multiple security functions (e.g., data encryption, access control) to ensure secure and stable system operation.

Application Areas

Industrial Automation: Used in manufacturing for equipment control on production lines, process monitoring, etc., to automate and optimize production processes, improving efficiency and product quality.

Energy Industry: Suitable for energy sectors such as power, petroleum, and chemicals, enabling parameter control and equipment monitoring/management in energy production to ensure safe and efficient operations.

Infrastructure: Applied in infrastructure fields like water treatment, sewage processing, and traffic control to achieve automated control and monitoring of related equipment and systems, ensuring normal operation.

Other Fields: Also applicable in industries such as pharmaceutical manufacturing, food and beverage processing, robotics control, and building automation, providing reliable control and management for various industrial processes.

Energy Industry: Suitable for energy sectors such as power, petroleum, and chemicals, enabling parameter control and equipment monitoring/management in energy production to ensure safe and efficient operations.

Infrastructure: Applied in infrastructure fields like water treatment, sewage processing, and traffic control to achieve automated control and monitoring of related equipment and systems, ensuring normal operation.

Other Fields: Also applicable in industries such as pharmaceutical manufacturing, food and beverage processing, robotics control, and building automation, providing reliable control and management for various industrial processes.

General Operation Guide for ABB PM866 3BSE093347R1

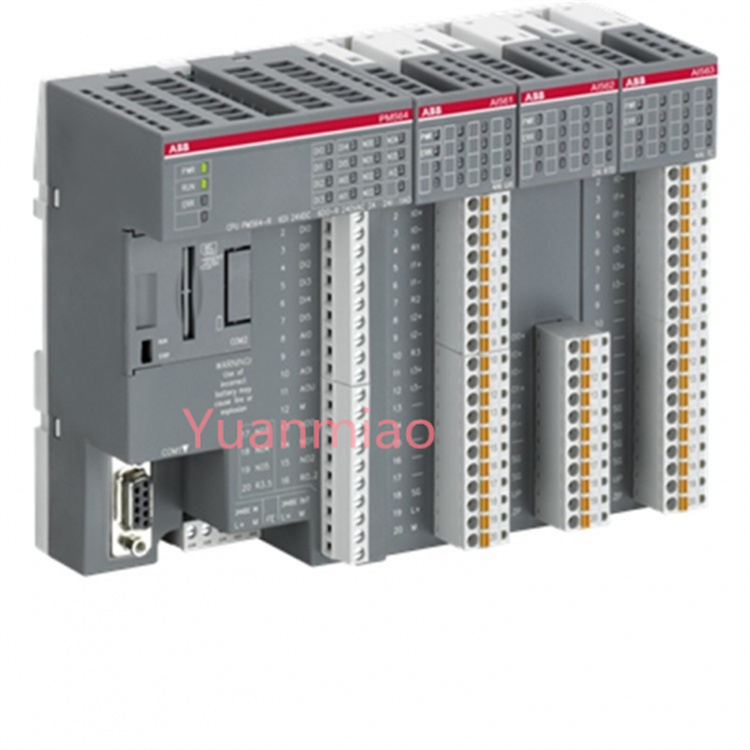

Hardware Installation

Installation Preparation: Ensure the environment meets requirements (e.g., temperature -20°C to 60°C, no strong electromagnetic interference). Prepare DIN rails and necessary installation tools.

Rail Mounting: Install the PM866 module on a DIN rail using its unique sliding and locking mechanism. Ensure secure installation and check for tight connections to prevent looseness.

Terminal Connections: Connect power input terminals (typically L+, L-, SA, SB) as per the manual, ensuring the power voltage meets the module’s requirements (usually 24V DC). Connect other relevant communication cables and bus connectors for I/O modules, ensuring reliable connections without looseness or oxidation.

Rail Mounting: Install the PM866 module on a DIN rail using its unique sliding and locking mechanism. Ensure secure installation and check for tight connections to prevent looseness.

Terminal Connections: Connect power input terminals (typically L+, L-, SA, SB) as per the manual, ensuring the power voltage meets the module’s requirements (usually 24V DC). Connect other relevant communication cables and bus connectors for I/O modules, ensuring reliable connections without looseness or oxidation.

Software Configuration

Programming Software Installation: Install programming software compatible with the PM866, such as ABB’s 800xA Control Builder.

Communication Setup: Establish a communication link with the PM866 via the programming software. Set the computer’s IP address to the same subnet as the module, using the module’s default IP or configuring it through specific tools.

Project Creation and Configuration: Create a new project in the programming software and configure various parameters for the PM866 based on application needs, including:

Communication Setup: Establish a communication link with the PM866 via the programming software. Set the computer’s IP address to the same subnet as the module, using the module’s default IP or configuring it through specific tools.

Project Creation and Configuration: Create a new project in the programming software and configure various parameters for the PM866 based on application needs, including:

- Communication parameters (select protocols like Modbus, Profibus, Ethernet and configure accordingly).

- I/O configuration (define connected I/O module types and addresses).

- Control logic programming (write control programs using languages like ladder diagram or function block diagram).

Download and Debugging: Download the programmed logic and configurations to the PM866. Ensure the module is in write mode before downloading, and avoid interrupting power or communication during the process. After download, perform online debugging by monitoring variables and checking status indicators to identify syntax or logic issues.

Routine Maintenance

Status Inspection: Regularly check the module’s LED indicators (power, communication, operation, etc.) to monitor working status. Refer to the manual for troubleshooting if abnormal indicators appear.

Cleaning: Clean the module’s surface periodically (e.g., quarterly) to prevent dust accumulation that may affect heat dissipation and performance. Use a clean soft cloth or compressed air for cleaning.

Wiring Check: Inspect power connections, communication cables, and I/O terminals for looseness, tightening them promptly to avoid faults due to poor contact.

Data Backup: Regularly backup the module’s programs and configuration files to external storage (e.g., USB drives, hard disks) via programming software to prevent data loss from hardware failures or accidents.

Firmware Update: Monitor ABB’s official website for firmware updates for the PM866. Download and install updates as instructed to fix known defects and enhance performance, ensuring data is backed up before upgrading.

Cleaning: Clean the module’s surface periodically (e.g., quarterly) to prevent dust accumulation that may affect heat dissipation and performance. Use a clean soft cloth or compressed air for cleaning.

Wiring Check: Inspect power connections, communication cables, and I/O terminals for looseness, tightening them promptly to avoid faults due to poor contact.

Data Backup: Regularly backup the module’s programs and configuration files to external storage (e.g., USB drives, hard disks) via programming software to prevent data loss from hardware failures or accidents.

Firmware Update: Monitor ABB’s official website for firmware updates for the PM866. Download and install updates as instructed to fix known defects and enhance performance, ensuring data is backed up before upgrading.