Description

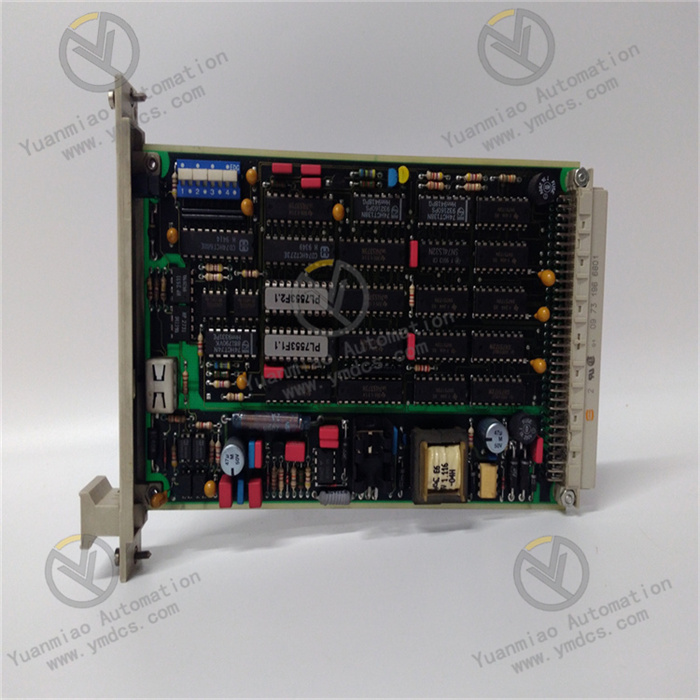

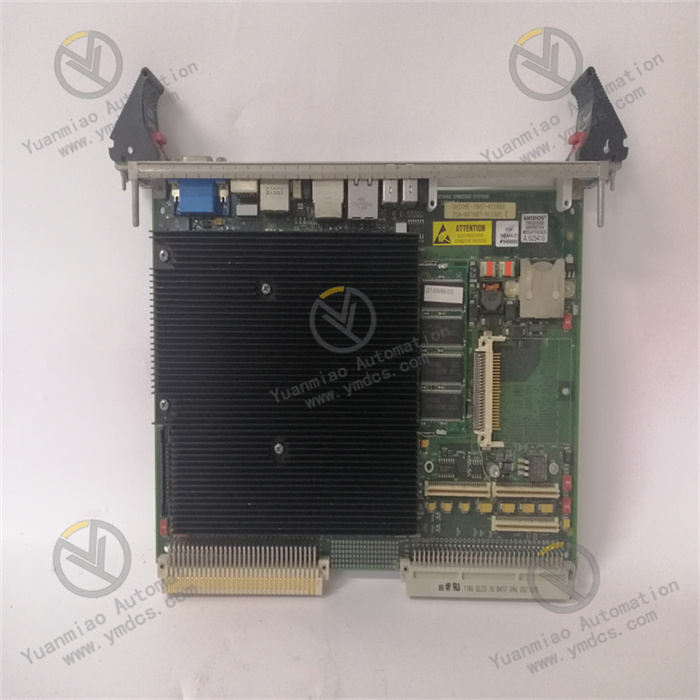

Bently Nevada 3500/32M 149986-02

The Bently Nevada 3500/32M 149986-02 is a 4-channel relay module designed for the Bently Nevada 3500 monitoring system. It is a full-height module that provides four relay outputs and can be installed in any slot to the right of the Transient Data Interface (TDI) module. Each output can be independently programmed to execute voting logic, with hysteresis selectable by the user between 0.2 and 2.5 volts.

The Bently Nevada 3500 monitoring system is a high-end condition monitoring system for rotating machinery, widely used in power, petrochemical, metallurgy, aerospace, and other industries. It is used to real-time monitor key parameters of rotating equipment such as steam turbines, compressors, and fans, including vibration, displacement, speed, and temperature, ensuring safe equipment operation and preventing unplanned downtime.

System Composition and Functional Modules

The 3500 system adopts a modular design, primarily consisting of the following components:

1. Frame and Power Module

- Frame: Provides a modular installation structure, supporting various sizes (e.g., 19-inch standard rack) and accommodating monitoring modules with different functions.

- Power Module: Supplies stable power to the entire system, supporting redundant configuration (dual-power backup) to ensure power reliability.

2. Monitoring Modules (Core Functional Units)

- Vibration Monitoring Module:

Measures shaft vibration (e.g., displacement, velocity, acceleration) and casing vibration, supporting inputs from eddy current sensors, velocity sensors, etc.

Provides vibration trend analysis and spectrum analysis (FFT) to identify typical issues such as unbalance, misalignment, and bearing faults. - Displacement Monitoring Module:

Monitors parameters such as shaft displacement, differential expansion, and axial movement to prevent friction between rotating and stationary components (e.g., axial displacement protection for steam turbines). - Speed and Key Phasor Module:

Measures rotor speed, zero speed, and phase signals (key phasor) for synchronous vibration analysis and equipment start/stop control. - Temperature Monitoring Module:

Connects to sensors such as thermocouples (TC) and resistance temperature detectors (RTD) to monitor bearing temperature, lubricating oil temperature, etc. - Process Variable Module:

Acquires process parameters such as pressure, flow, and level for comprehensive multi-parameter monitoring. - Communication and Interface Module:

Supports multiple communication protocols (e.g., Modbus, Profinet, Ethernet/IP) for real-time data interaction with DCS, PLC, or upper-level systems (e.g., Bentley’s Plantstate Suite).

3. Sensors and Cables

- Eddy Current Sensors: Used for non-contact measurement of shaft displacement and vibration with high precision (resolution up to micrometer level).

- Velocity/Acceleration Sensors: Measure casing vibration, suitable for high-frequency vibration monitoring.

- Speed Sensors: Reluctance or photoelectric sensors providing speed and key phasor pulse signals.

- Specialized Cables: Shielded cables connect sensors to monitoring modules to reduce electromagnetic interference (EMI).

Technical Features

- High Reliability:

Industrial-grade hardware design supports wide temperature ranges (-40°C ~ +85°C) and resistance to vibration and shock, suitable for harsh industrial environments.

Modules support online hot-swapping, eliminating the need for downtime during maintenance and reducing production interruptions. - High Precision and Real-Time Performance:

High sampling rates (up to 20 kHz or higher) capture real-time transient vibration signals (e.g., critical speeds during start/stop processes).

Built-in digital signal processing (DSP) enables real-time spectrum analysis, waveform acquisition, and trend storage. - Flexible Configuration and Scalability:

A single frame can accommodate up to 14 monitoring modules, supporting mixed configurations (e.g., vibration, displacement, speed modules).

System expansion via extended frames meets monitoring needs for large unit clusters. - Advanced Fault Diagnosis Capability:

Built-in alarm and protection logic supports multi-level threshold settings (warning, danger), triggering relay outputs or interlock shutdowns.

Provides historical data storage and playback to help engineers analyze pre-fault operation trends (e.g., sudden changes in vibration amplitude).

Detailed Technical Parameters of Bently Nevada 3500/32M 149986-02 Relay Module

1. Physical Specifications

| Parameter | Details |

|---|---|

| Dimensions | Full-height module, compliant with Bently Nevada 3500 frame standard size. |

| Weight | Approximately 0.5 kg (subject to actual product). |

| Installation | Can be installed in any slot to the right of the TDI module in the 3500 frame. |

| Enclosure Material | Metal casing with anti-interference and protection capabilities. |

2. Electrical Parameters

| Parameter | Details |

|---|---|

| Supply Voltage | - Operating voltage: 24 V DC (typical) - Voltage range: 18~32 V DC - Power consumption: ≤10 W |

| Relay Outputs | - Channels: 4 independent relay outputs - Contact type: SPDT (Single Pole Double Throw) - Rated current: 5 A @ 250 V AC / 30 V DC - Maximum switching power: 1250 VA / 150 W |

| Logic Inputs | - Input type: Digital (TTL compatible) - Input voltage range: 0~5 V DC - Input impedance: ≥10 kΩ |

| Voting Logic | Each output can be independently programmed to support various voting logics (e.g., 1-out-of-1, 2-out-of-2, 2-out-of-3, etc.). |

| Hysteresis | User-configurable, range 0.2~2.5 V (typical value 0.5 V). |

3. Performance Parameters

| Parameter | Details |

|---|---|

| Response Time | - Actuation time: ≤10 ms - Release time: ≤5 ms |

| Insulation Resistance | ≥100 MΩ (tested at 500 V DC). |

| Dielectric Strength | - Between channels: 1500 V AC, 1 minute - Between channels and casing: 1500 V AC, 1 minute |

| Electromagnetic Compatibility | Compliant with industrial standards (e.g., IEC 61000), strong anti-interference capability. |

| Operating Temperature Range | -20°C ~ +70°C (storage temperature: -40°C ~ +85°C). |

| Humidity Range | 5%~95% RH (non-condensing). |

4. Communication and Interfaces

| Parameter | Details |

|---|---|

| Communication Protocol | Supports communication with the 3500 system main frame (via internal bus). |

| Diagnostic Interface | - LED indicators: Show module status and channel status. - Optional: Remote diagnostics via 3500 frame software. |

5. Typical Application Scenarios

- Rotating Machinery Protection: Provides vibration alarm and interlock shutdown functions for turbines, compressors, pumps, etc.

- Process Monitoring: Implements logic control of parameters such as temperature, pressure, and flow in conjunction with sensors.

- Redundant Systems: Serves as a redundant output in critical control systems to enhance reliability.

Application Fields

The 3500 system to which this module belongs can be widely applied to monitoring various rotating machinery, including but not limited to:

- Turbines: Monitor key parameters such as vibration and speed to ensure safe and stable operation.

- Compressors: Real-time monitor operational status to detect potential faults promptly.

- Pumps: Monitor vibration, temperature, and other parameters to ensure normal operation.

- Motors: Monitor operational conditions such as vibration and current to prevent motor failures.

Common Faults and Solutions

- Relay Faults: If a relay fails to operate, first check for input signals and ensure they are within the normal range. If signals are normal, the relay itself may be damaged and requires module replacement.

- Communication Faults: Verify that communication lines are properly connected and communication parameters (e.g., protocol, baud rate) are correctly set. Ensure compatibility with other devices’ communication protocols and parameters.

- Module Faults: Refer to the module’s fault codes for troubleshooting. Try restarting the module or the entire system; if issues persist, contact the manufacturer for repair or replacement.

Other Brand-Related Products

Enterasys STK-RPS-150PS P0973BP Redundant Power Supply Module

EATON XV-440-10TVB-1-13-1 Display Screen Module

ABB PM856AK01 3BSE066490R1 | AC 800M Processor Unit Kit

ABB PPD113B01-20-111000 AC800PEC Power Module

NI PXIE-8840QC | Embedded Controller