Description

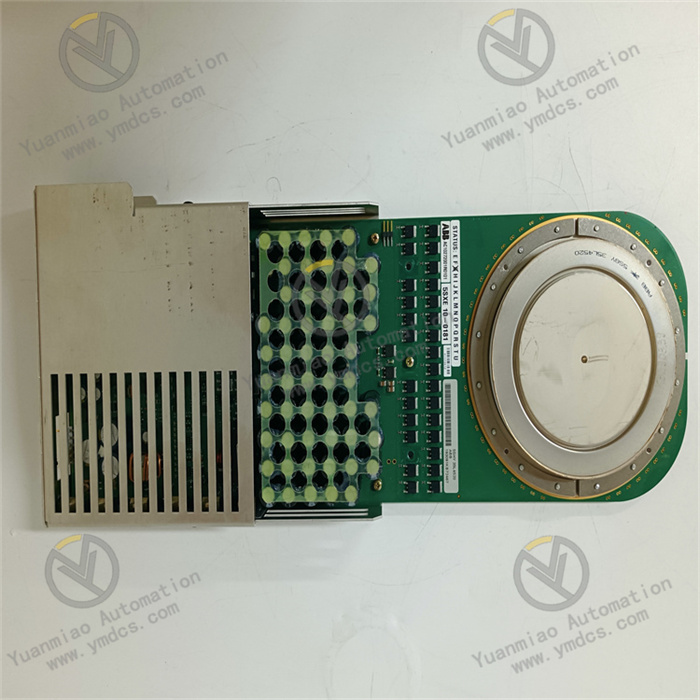

ABB PP835 3BSE042234R1 is an operator panel belonging to the Panel 800 series.

Functional Features

- Powerful Human-Machine Interaction: Equipped with built-in functions such as text display, dynamic indication, time channels, alarm handling, and recipe management, enabling easy monitoring and control of processes and equipment in the system.

- Convenient Configuration: Configured via a personal computer using the Panel Builder 800 configuration tool. Configured projects can be transferred and stored in the operator panel.

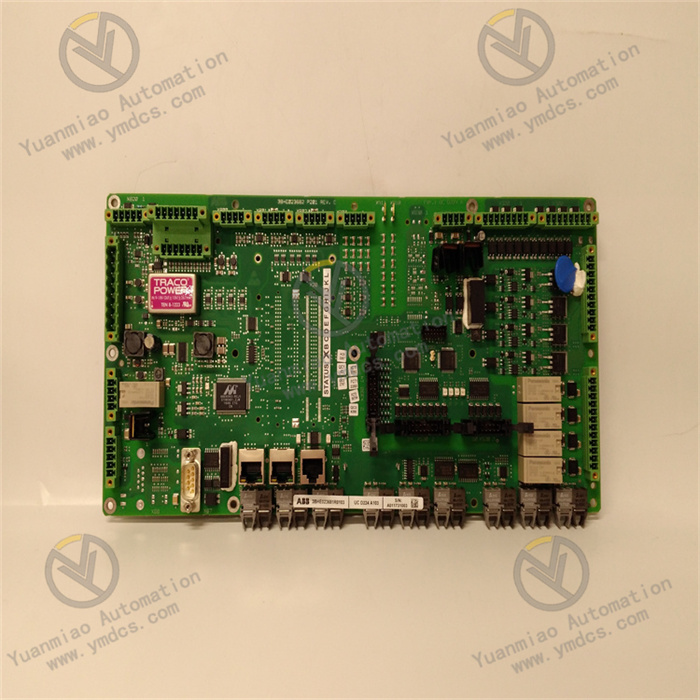

- Extensive Connectivity: Capable of connecting to various automation devices such as PLCs, servo drives, or inverters, suitable for different industrial automation scenarios.

Technical Parameters

Display Parameters

- Screen Size: 6.5 inches

- Display Type: TFT-LCD

- Resolution: 640×480 pixels

- Active Display Area: 131.5×98.6mm

- Backlight: CCFL

Touch Parameters

- Touch Material: Polyester film on glass

- Cover Material: Autotex F157/F207*

Environmental Parameters

- Operating Relative Humidity: 5%–85% (non-condensing)

- NEMA Protection Rating: 4X (suitable for indoor use only)

Electrical Parameters

- Operating Voltage: 220V

- Rated Impulse Withstand Voltage: 1000V

Other Parameters

- Net Weight: 1.555kg

- Configuration Software: Panel Builder 800

Application Scenarios

Widely used in industrial fields such as aluminum, automotive, aviation, and metallurgy. It can be applied to music fountain control systems, achieving precise control of fountains by integrating with devices like inverters, and perfectly combining the spirituality of water, the beauty of music, and the colors of lighting.

General Configuration Steps for ABB PP835 3BSE042234R1 Operator Panel

- Preparation: Ensure the Panel Builder 800 configuration tool is installed on the personal computer, and connect the operator panel to the computer via a suitable communication cable (e.g., Ethernet cable).

- Create a New Project: Open the Panel Builder 800 software, click "New Project", enter the project name and relevant descriptions, and select PP835 as the target device model.

- Design Interface Layout: Create various screens in the project, such as the main interface, parameter settings interface, and alarm display interface. Design the interface by selecting appropriate graphic elements, text boxes, buttons, and other components from the graphics library, using drag-and-drop operations for layout, and setting their properties (e.g., size, position, color, display text). For example, add an indicator light graphic to show the equipment operating status, set its color changes under different states, and add a text box to display the current temperature value.

- Configure Functional Logic: Configure functional logic for components on the interface. For example, add processing logic for button press events to trigger corresponding actions, such as opening another screen, executing a control command, or modifying a parameter value. For data display components, set up connections with PLCs or other data sources to obtain and display real-time data. For instance, associate the temperature display text box with the register storing temperature data in the PLC to achieve real-time temperature display.

- Set Communication Parameters: Configure communication parameters (e.g., communication protocol, IP address, port number) between the operator panel and external devices (e.g., PLCs, inverters) in Panel Builder 800. Ensure the communication parameters match those of the external devices to establish a reliable connection. If communicating with a PLC via the Modbus protocol, set correct parameters such as Modbus address, baud rate, data bits, and stop bits.

- Compile the Project: After completing interface design and functional configuration, click the "Compile" button to check for syntax errors or other issues. If errors are found, modify them according to the prompt messages until compilation is successful.

- Download the Project to the Operator Panel: Download the compiled project to the PP835 operator panel. Ensure the panel is powered on and in a state ready to receive the download before starting. After the download is complete, the operator panel will automatically restart to apply the new configuration.

- On-Site Debugging and Optimization: Install the operator panel in the actual industrial site, connect it to relevant devices, and power it on. Check whether the communication between the operator panel and external devices is normal, and whether the interface display and functional operations meet expectations. Adjust and optimize the interface layout, functional logic, or communication parameters according to actual operation conditions to achieve optimal performance. For example, if inaccurate data display is found, check the communication settings and data sources and make corresponding adjustments.

Related Products

ABB 500TRM02 1MRB150011R1 Coupler Module

Bailey INIIT13 Transfer Module

ABB 5SHX14H4502 3BHB003230R0101 IGCT Module

ABB PM866 3BSE050200R1 | AC 800M Processor Unit Kit

ABB FI810F 3BDH000030R1 | AC 800F Communication Module