Description

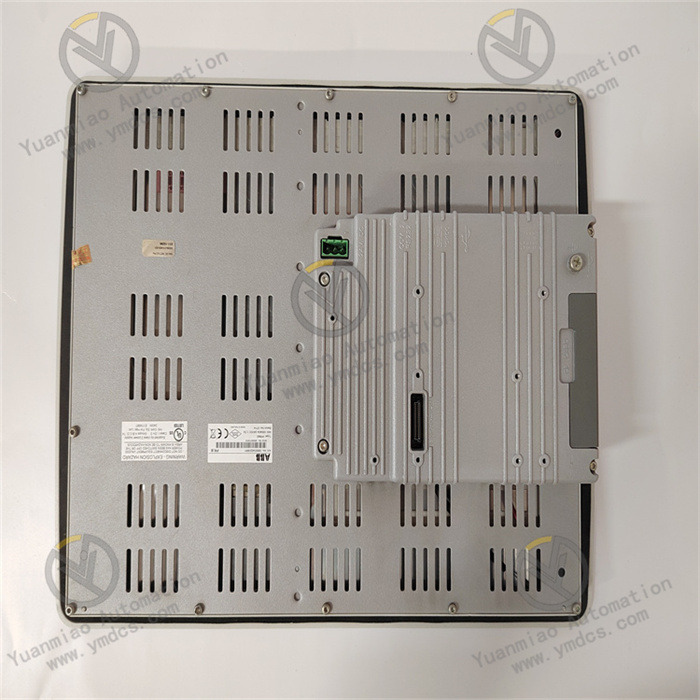

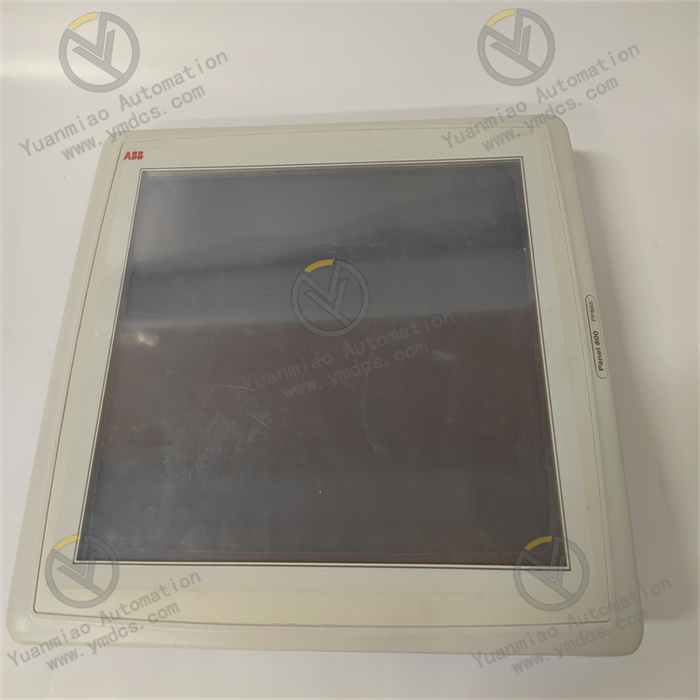

ABB PP865 3BSE042236R1 15" Touch Panel

The ABB PP865 3BSE042236R1 is a 15-inch Human-Machine Interface (HMI) touch panel, belonging to the ABB Panel 800 product series. It is mainly used in the field of industrial automation, providing operators with an intuitive operation interface to monitor and control the production process. Functional Features High-resolution Display: With a resolution of 1024×768 pixels, it can clearly and accurately present images and information, facilitating operators to view various data, graphics, and status indications. Touchscreen Input: Adopting touchscreen technology, operators can perform intuitive interactive operations through the touchscreen, such as clicking, swiping, zooming, etc., which simplifies the user operation and data input process. Function Key Assistance: In addition to the touchscreen function, it is also equipped with function keys, providing additional control options to enable users to perform quick operations, such as quickly switching pages and calling specific functions. System Compatibility: It can be seamlessly integrated with ABB's Panel 800 system, and can communicate and work in collaboration with other devices and systems in a unified automation environment, achieving more efficient control and management. Multiple Communication Ports: It is equipped with a rich variety of communication ports, such as 2 Ethernet ports, 2 USB 3.0 interfaces, 2 USB 2.0 interfaces, 1 HDMI interface, and 1 RS-232 interface. It can be conveniently connected to other devices for data transmission, such as PLCs, sensors, computers, etc., to meet the requirements of different industrial application scenarios.

Technical Parameters Display Type: TFT-LCD liquid crystal display, providing clear image display effects, 64K color display, and being able to present rich graphics and color information. Backlight Lifespan: When the ambient temperature is +25°C, the lifespan of the CCFL backlight is more than 35,000 hours, which has a relatively long service life and reduces the frequency of equipment replacement due to backlight aging. Real-time Clock: It has a real-time clock function with an accuracy of ±20ppm. Adding the errors caused by the ambient temperature and power supply voltage, the maximum error per month at 25°C is 1 minute. It can be used for operations such as recording the time of event occurrence and performing timing control. Protection Level: The front panel reaches the IP65/IP66 protection level, which can resist the influence of dust, water splashes, and other harsh environmental factors, and is suitable for various industrial field environments. Operating Temperature: The operating temperature range is from -30°C to 70°C, and it can work stably within a relatively wide temperature range, adapting to the temperature conditions of different industrial environments. Application Areas Industrial Automation: In industries such as manufacturing, chemical, pharmaceutical, food, and beverage industries, it is used to create HMI panels for monitoring and controlling the production process, achieving remote control, status monitoring, and parameter adjustment of production equipment, and improving production efficiency and quality. Energy Management: In the power industry and energy management systems, it can be used to create user interfaces for monitoring and controlling power plants, substations, and the power grid, helping operators to understand the operating status of the power system in real time and carry out effective energy scheduling and management. Building Automation: It is used for the control interfaces of building automation systems, such as air conditioning, lighting, security systems, etc., facilitating managers to centrally control and manage various devices within the building and achieving intelligent building management. Water Treatment and Environmental Monitoring: In the fields of water treatment and environmental monitoring, it can be used to create control panels for monitoring the water treatment process, sewage treatment, and environmental monitoring, achieving real-time monitoring and control of water quality parameters and equipment operating status, and ensuring water quality and environmental safety.