Description

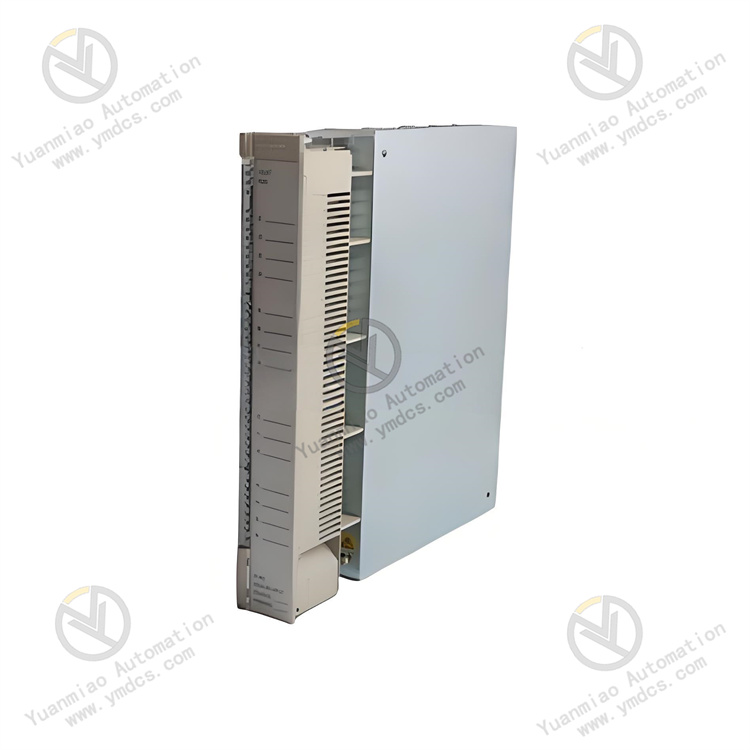

ABB PM866A 3BSE076359R1

I. Basic Information

- Full Model: PM866A 3BSE076359R1545

- Series: ABB AC 800M controller series, serving as the core processor module in industrial automation control systems.

- Purpose: As the central processing unit (CPU) of a PLC (Programmable Logic Controller), it executes control logic, processes data, and communicates with peripheral devices, suitable for medium to large industrial automation systems.

II. Core Functions and Features

1. Computing and Processing Capability

- Processor Architecture: Adopts high-performance multi-core processors (such as ARM Cortex-A series) with a main frequency ≥1GHz, supporting high-speed logical operations and complex algorithm processing.

- Memory Configuration:

- System memory (RAM): Typically ≥2GB, supporting real-time data caching and multi-task parallel processing;

- Flash memory: ≥8GB, used for storing program codes, configuration files, and historical data.

- Processing Speed: Instruction execution time ≤0.1μs (for typical logical operations), supporting millisecond-level real-time control.

2. Communication and Interfaces

- Internal Bus: High-speed interconnection with I/O modules and communication modules via backplane buses (such as PCIe or dedicated industrial buses), with data transmission rates ≥100Mbps.

- External Communication Interfaces:

- 2× Ethernet interfaces (10/100/1000Mbps), supporting industrial protocols such as Profinet, EtherNet/IP, and Modbus TCP;

- 2× serial ports (RS-232/RS-485), used for point-to-point communication or connecting third-party devices;

- Optional fiber optic interface, supporting long-distance redundant communication (such as ring network topology).

- Redundancy Function: Supports hot standby redundancy (1+1 redundancy configuration), with automatic switching time between primary and standby CPUs ≤50ms to ensure high system availability.

3. Storage and Expansion

- Storage Expansion: Supports SD card or CF card expansion for program backup and data log storage (maximum capacity ≥32GB).

- I/O Expansion: Can connect up to 256 I/O modules (via expansion racks), supporting mixed configurations of analog, digital, and communication modules.

4. Diagnostic and Safety Features

- Self-Diagnosis Function: Real-time monitoring of CPU temperature, memory utilization, and communication status, with alarms via LED indicators (such as ERROR, WARNING) and system logs in case of faults.

- Safety Certification: Complies with IEC 61508 SIL 2 safety integrity level, supports fail-safe design, and is suitable for scenarios requiring safety interlocks.

III. Technical Parameters

| Parameter Dimension | Specific Indicators |

|---|---|

| Processor | Multi-core ARM processor, main frequency ≥1GHz |

| Memory | RAM 2GB, Flash 8GB, supporting SD card expansion |

| Communication Interfaces | 2× Ethernet (10/100/1000Mbps), 2× RS-232/485, optional fiber optic interface |

| Redundancy Support | Hot standby redundancy (1+1), switching time ≤50ms |

| Operating Voltage | DC 24V (±10%), power consumption ≤20W |

| Operating Temperature | -20℃~+60℃ (industrial grade), humidity 5%~95% (non-condensing) |

| Protection Level | IP20 (indoor installation), compliant with EN 61131-2 standard |

IV. Application Scenarios

Process Industry Control

- DCS (Distributed Control Systems) in chemical, petroleum, and natural gas production, such as reactor temperature control and distillation column liquid level regulation.

- Power industry: Substation automation, generator set control, and power grid dispatching systems.

Discrete Manufacturing Automation

- Robotic collaborative control in automotive production lines, intelligent warehousing logistics systems (AGV scheduling).

- High-speed logic control for filling lines and packaging equipment in the food and beverage industry.

Energy and Infrastructure

- Automatic control of pumps/valves in wastewater treatment plants, coordinated management of inverters in photovoltaic power stations.

- Central control units for rail transit signaling systems and building automation (BMS).

V. Installation and Usage Key Points

Installation Method

- Adopts DIN rail installation or backplane fixing, requiring use with an AC 800M controller rack to ensure heat dissipation space (module spacing ≥20mm).

Wiring Specifications

- Use shielded cables for power wiring with a grounding resistance ≤1Ω, avoiding parallel laying with power cables (spacing ≥30cm).

- CAT6 shielded network cables are recommended for Ethernet interfaces, supporting redundant network topologies (such as ring, star).

Programming and Configuration

- Use ABB Control Builder M software (based on IEC 61131-3 standards), supporting programming languages such as Ladder Diagram (LD) and Structured Text (ST).

- Redundant systems require configuring primary-backup switching logic via software and performing offline/online download tests.

Maintenance Notes

- Regularly inspect the operating status of cooling fans (recommended to clean dust filters quarterly);

- Ensure the system is powered off when replacing the CPU module, or perform "online replacement" in hot standby redundancy mode (follow manual procedures).

VI. Comparison with Similar Products (vs Siemens S7-400 CPU 416-3)

| Parameter Dimension | ABB PM866A | Siemens S7-400 CPU 416-3 |

|---|---|---|

| Processor Architecture | Multi-core ARM | Single-core Intel® processor |

| Computing Speed | Instruction cycle ≤0.1μs | Instruction cycle ≤0.08μs (bit operation) |

| Memory Capacity | RAM 2GB, Flash 8GB | RAM 2GB, built-in load memory 4MB |

| Communication Interfaces | 2× Ethernet (with redundancy), optional serial ports | 1× Ethernet, requiring optional communication modules |

| Redundancy Support | Hot standby redundancy (1+1) | Requires additional redundancy kit (S7-400H) |

| Application Scenarios | Medium to large systems, focusing on openness and expandability | Large systems, suitable for Siemens ecosystem integration |

| Programming Software | Control Builder M | STEP 7 |

VII. Typical Supporting Modules

- I/O modules: Such as AI835 (analog input), DI830 (digital input), DO830 (digital output), interconnected with PM866A via the backplane.

- Communication modules: Such as CM852 (Profinet master), CM856 (EtherNet/IP interface), expanding external protocol support.

- Redundancy modules: Such as RM850 (redundancy manager), used to build 1+1 hot standby systems.