Description

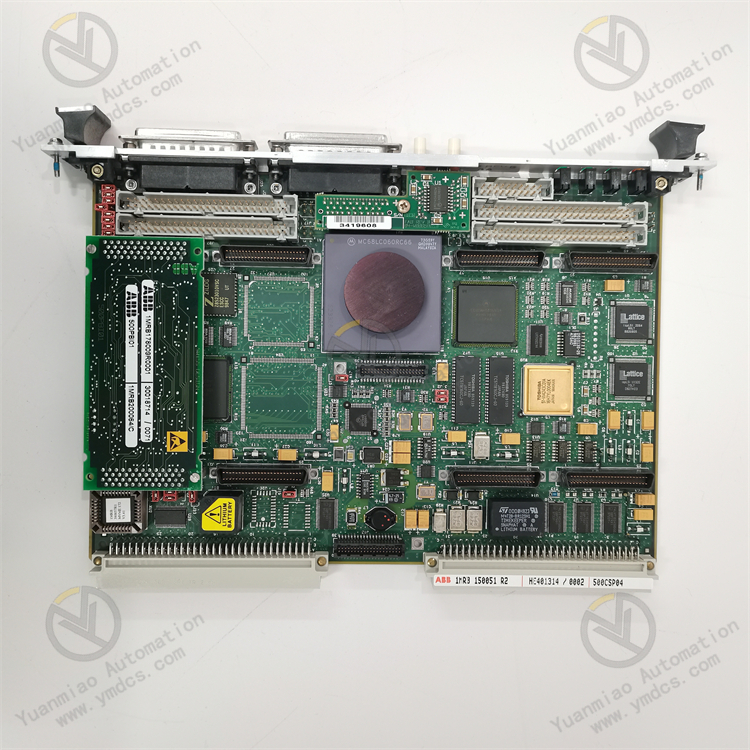

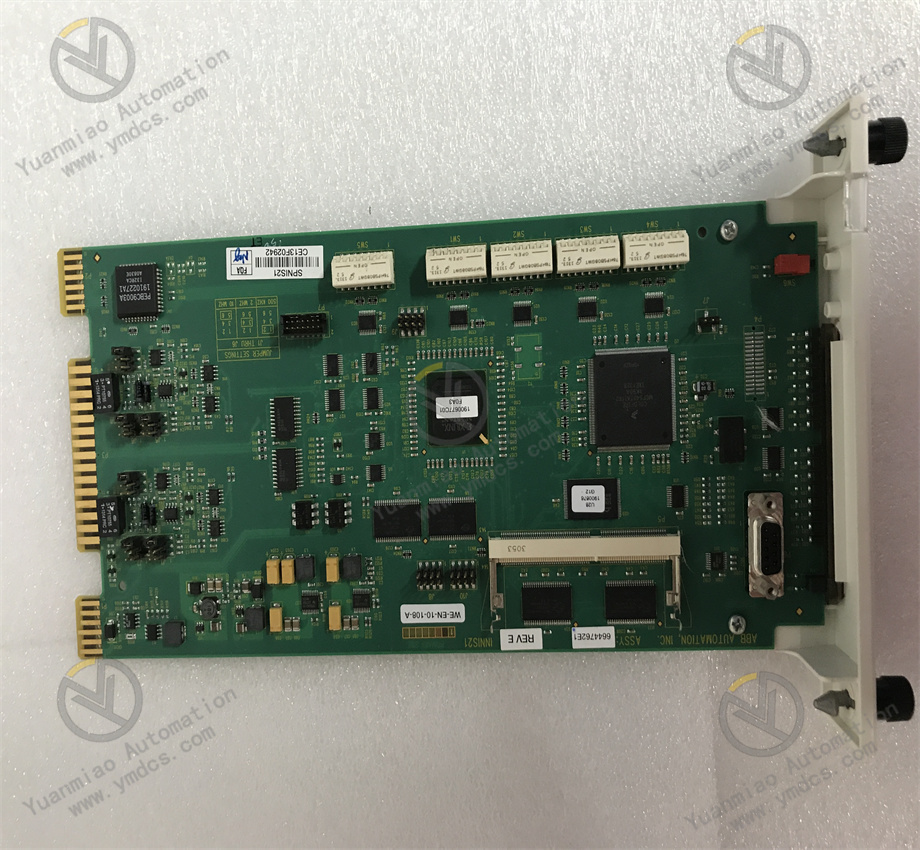

ABB CI930F 3BDH001010R0002

I. Basic Information

Manufacturer: ABB

Model: CI930F

Product Number: 3BDH001010R0002

Series: Suitable for ABB AC800F control system (a distributed control system in the industrial automation field).

Application Scenario: As a high-performance Analog Input (AI) module, it is used for continuous signal acquisition and processing in industrial processes, such as monitoring analog parameters like temperature, pressure, and flow.

Model: CI930F

Product Number: 3BDH001010R0002

Series: Suitable for ABB AC800F control system (a distributed control system in the industrial automation field).

Application Scenario: As a high-performance Analog Input (AI) module, it is used for continuous signal acquisition and processing in industrial processes, such as monitoring analog parameters like temperature, pressure, and flow.

II. Technical Parameters

| Parameter | Details |

|---|---|

| Number of Channels | 8 analog input channels (supporting differential or single-ended input). |

| Signal Types | - Voltage: ±10V, 0-10V, ±5V, etc. - Current: 4-20mA, 0-20mA, etc. - Thermocouples (e.g., Type K, J, T) - Resistance Temperature Detectors (RTD, e.g., Pt100, Ni1000) |

| Resolution | 16-bit (high-precision conversion ensures signal acquisition accuracy). |

| Sampling Frequency | Typical value: Up to 250Hz per channel (configurable, supports high-speed acquisition). |

| Operating Voltage | 24V DC (±10%), powered by the control system. |

| Communication Interface | Based on the FBP (Field Bus Processor) bus of the ABB AC800F system, supporting redundant communication. |

| Protection Class | IP20 (requires installation in a control cabinet for dust and solid 异物 protection). |

| Ambient Temperature | -40°C ~ +70°C (wide temperature operation, adapting to harsh industrial environments). |

| Humidity | 5% ~ 95% (non-condensing). |

| Isolation Features | Electrical isolation between channels, strong anti-interference capability (isolation voltage: 500V AC for 1 minute). |

III. Functional Features

Multi-Signal Compatibility

- Supports various industrial standard signals such as voltage, current, thermocouples, and RTDs, requiring no additional hardware conversion for flexible adaptation.

- Built-in signal conditioning circuits enable direct connection to sensor or transmitter signals.

High Precision and Reliability

- 16-bit ADC conversion, combined with digital filtering, reduces noise interference, suitable for precision control scenarios (e.g., chemical, pharmaceutical, power industries).

- Supports channel-level diagnostics to monitor real-time anomalies such as signal overrange, open circuits, and short circuits.

System Integration and Redundancy

- Seamlessly integrated into the ABB AC800F system, supporting hot-swapping (subject to system configuration), for convenient maintenance.

- Bus-level redundancy design enhances system availability and reduces downtime risks caused by single-point failures.

Intelligent Diagnosis and Configuration

- Configure parameters (e.g., signal type, range, filter time) via ABB Control Builder F software, supporting online modifications.

- Module status indicators (e.g., power, communication, channel faults) visually display operating status for quick troubleshooting.

IV. Application Areas

- Process Industry: Monitoring process parameters in chemical, oil & gas, and pharmaceutical industries (e.g., reactor temperature, pipeline pressure).

- Power Industry: Analog signal acquisition for power plant equipment (e.g., generator winding temperature, steam flow).

- Manufacturing Industry: Precision control in automated production lines (e.g., pressure monitoring in robot spraying systems, liquid level measurement in food processing).

- Municipal Engineering: Monitoring and controlling water quality parameters (pH value, conductivity) in water treatment plants.

V. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| 1. Module unpowered (power light off) | - Loose or incorrectly wired power terminals - 24V power supply failure - Internal power circuit damage | - Check power connections and ensure correct polarity - Measure power voltage with a multimeter - Replace the module or contact ABB for repair |

| 2. Communication interruption (abnormal communication light flashing) | - Poor FBP bus cable contact - Module address conflict - Bus adapter failure | - Re-plug the bus cable and check terminal tightness - Ensure unique module address - Test the bus adapter |

| 3. No signal or abnormal value in a channel | - Faulty sensor/transmitter - Loose, short-circuited, or reverse-polarity wiring - Incorrect signal type configuration | - Test sensor output for normality - Check channel wiring against module manual pin definitions - Reconfigure the signal type |

| 4. Excessive value fluctuations or jumps | - Electromagnetic interference (e.g., near power cables) - Unshielded cables or poor grounding - Improper filter parameter settings | - Add shielding to signal cables and keep them away from interference sources - Ensure proper grounding - Increase software filter time constants |

| 5. Channel fault light on (channel error) | - Input signal out of range (e.g., 30mA input for 4-20mA channel) - RTD open circuit or thermocouple open | - Check if field signals exceed range - Measure circuit continuity with a multimeter and replace faulty sensors |

| 6. Module overheating | - Poor ventilation in the installation environment - Control cabinet temperature exceeding 70°C | - Optimize cabinet ventilation and install cooling fans - Ensure module spacing complies with installation specifications |

VI. Comparison of Related Models

| Model | Channels | Signal Types | Typical Application Scenarios |

|---|---|---|---|

| CI930F | 8 channels | Analog (voltage/current/RTD/thermocouple) | High-precision process parameter acquisition |

| CI932F | 16 channels | Analog (voltage/current) | High-density, low-cost signal acquisition |

| CI935F | 8 channels | Thermocouple-specific | High-temperature environments (e. |