Description

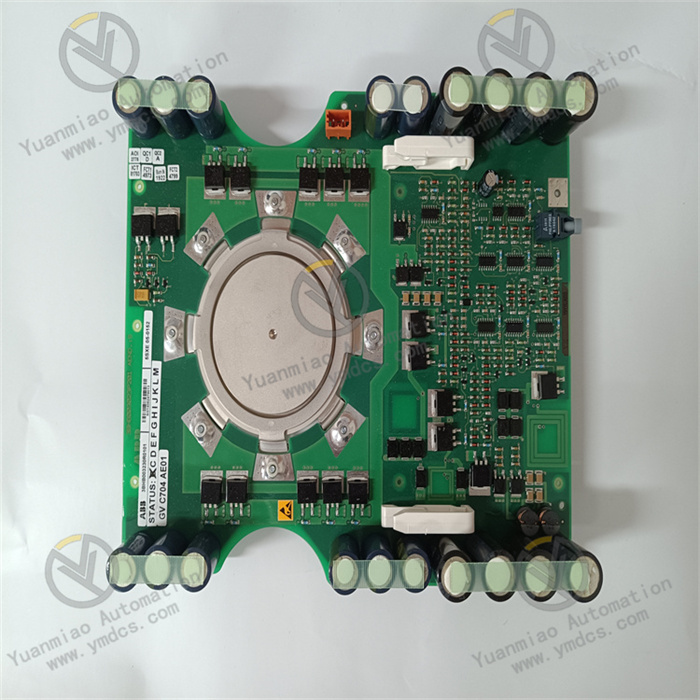

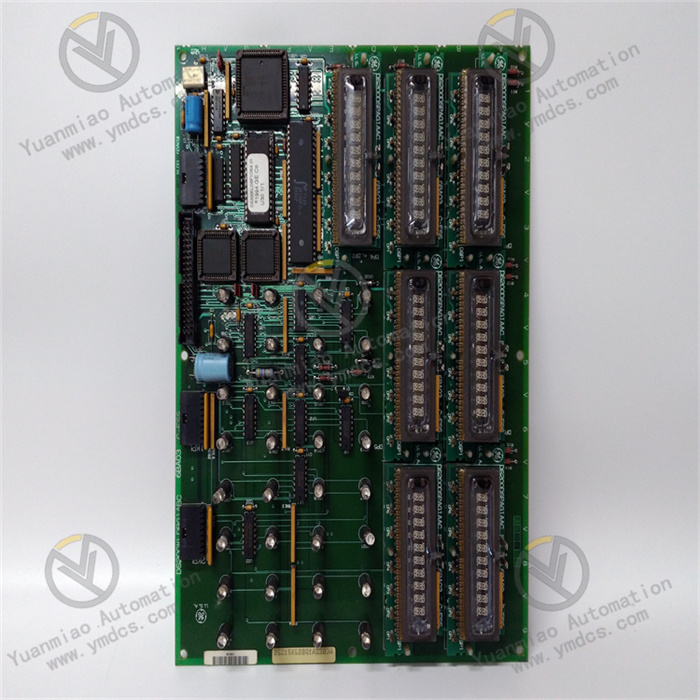

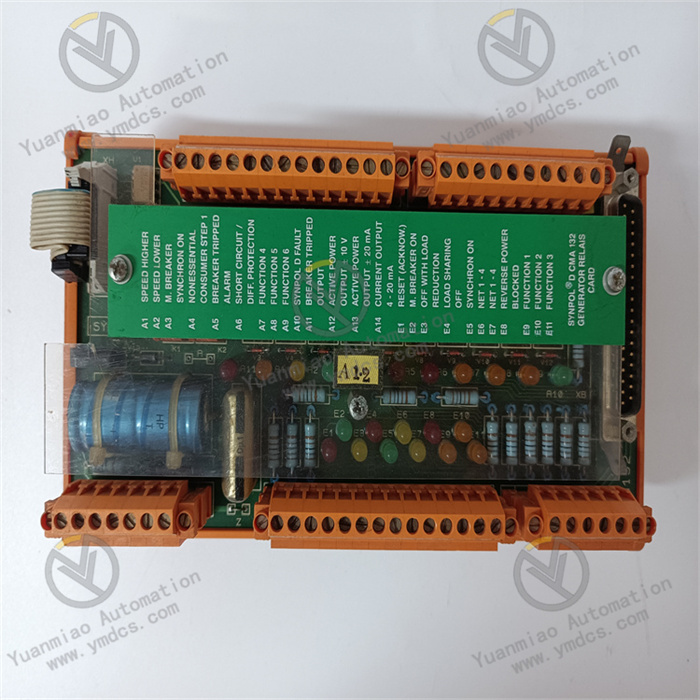

ABB CMA132 3DDE300412 is a generator relay terminal board. The relevant information is as follows: Functional Features: Connection Function: It provides safe and efficient connection for basic relay signals (such as start, stop and fault signals) in the generator control system. Easy Maintenance: It has a clear labeling scheme and a built-in diagnostic system, which is convenient for installation and maintenance. Communication Function: It supports RS-232 and RS-485 communication, and can perform data transmission and communication with other devices.

Technical Parameters: Size: 100mm×100mm×25mm. Weight: 0.5kg. Number of Terminals: 16. Terminal Type: Screw terminals. Voltage Rating: 690V AC. Current Rating: 10A. Power Supply: 24V DC. Operating Temperature Range: 0°C to +60°C. Certifications: CE, UL.

Application Areas: Power Industry: It is used for the monitoring, protection and control of generators to ensure the stability and safety of power production. Industrial Field: In various industrial scenarios where generators are used, such as factories and mines, it ensures the reliable operation of generators and provides stable power for production equipment.

Common Faults and Solutions: Communication Faults: They may be caused by damaged communication cables, loose interfaces or incorrect communication parameter settings. Check the cable connection, and replace it in time if there is any damage; ensure that the interface is firmly connected and re-plug it; confirm whether the communication parameters, such as baud rate, data bits and stop bits, are correctly set, and re-set them if there are any errors. Relay Faults: If the relay malfunctions, it may lead to abnormal signal transmission. Check whether the relay has phenomena such as overheating and damage, and detect its performance with professional detection equipment. Replace the relay if there are any problems. Power Supply Faults: Damaged power supply modules or abnormal input voltage (such as unstable voltage, reverse polarity, etc.) may cause problems. Check the power supply module to see if there is any overheating or damage, and replace it if there is; measure the input voltage to ensure that it is within the allowable range of the equipment, and check whether the power supply polarity is correct, and adjust it if it is incorrect.

For the power supply fault problems of ABB CMA132 3DDE300412, the following steps and methods can be used for troubleshooting and solution:

1. Check the power supply input: Use a multimeter to measure the input power supply voltage and confirm that it is within the voltage range specified by the device (such as 24V DC, etc.). If the voltage is abnormal, check the power supply lines, including power cords, sockets, switches, etc., to see if there are any open circuits, short circuits or poor contacts. Check whether the power supply polarity is correct. For DC power supplies, ensure that the positive and negative poles are correctly connected to avoid damage to the device due to reverse polarity. For AC power supplies, check whether the connection of the phase and neutral lines is correct. 2. Check the power supply module: Observe the appearance of the power supply module to see if there are signs of overheating, smoking, damaged components (such as bulging capacitors, burnt resistors, etc.). If any abnormalities are found, the power supply module needs to be replaced. Check the heat dissipation of the power supply module to ensure good ventilation and avoid faults caused by overheating. If the cooling fan is damaged, replace the fan in time. Measure the output voltage of the power supply module. Use a multimeter to measure the output terminal of the power supply module to confirm that the output voltage is stable and meets the requirements of the device. If the output voltage is abnormal, try to restart the power supply module. If the problem still exists, the power supply module needs to be replaced.

3. Check the fuses and protection devices:

Check whether the fuses in the power supply circuit are blown. If the fuses are blown, replace them with fuses of the same specification, and check if there are any faults such as short circuits in the circuit. Test the power supply after troubleshooting.

Check whether the overvoltage and undervoltage protection devices of the device are activated. If the protection devices are triggered, check whether the input voltage is abnormal. After restoring the normal voltage, manually reset the protection devices (if there is a reset button) or restart the device after troubleshooting.

4. Check the connection cables:

Check whether the power supply connection cables are intact, and whether there are any damage, breakage or poor contact. For plugs and sockets, ensure a firm connection, and replace the cables or plugs and sockets if necessary.

Check the power supply connection cables inside the device, and see if the soldered joints are loose and if the cables are aging. If any problems are found, repair or replace the corresponding cables.

5. Check the software and configuration:

Check the configuration parameters of the device to confirm that the power supply-related settings are correct. For example, whether the power supply mode, voltage range and other parameters are consistent with the actual power supply.

If the device has power management software, check whether the software is running normally and whether there are software faults causing power supply abnormalities. If necessary, update the software or restore the default configuration.