Description

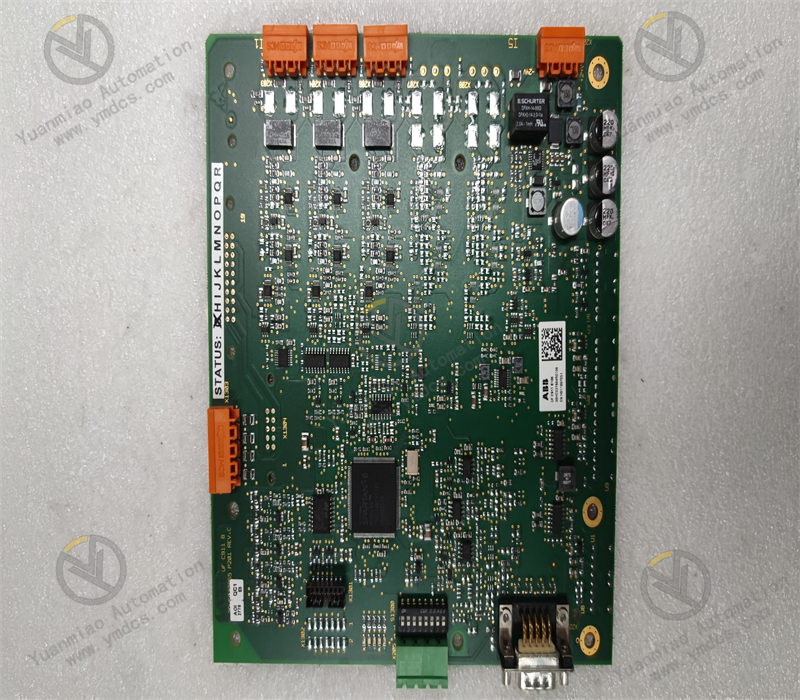

ABB SC510 3BSE003832R1

I. Overview

ABB SC510 3BSE003832R1 is a 4-channel asynchronous serial communication module, specially designed for the 800xA and Symphony®Plus distributed control systems. As a dedicated expansion module for the AC 800M controller, it can achieve high-speed interconnection with the main CPU (e.g., PM866) via the backplane bus, providing 4 configurable serial channels to enable flexible connection between the controller and various serial communication devices. It serves as a critical bridge linking traditional serial devices with modern DCS systems.

II. Core Features

Multi-channel Configurable Interfaces: Equipped with 4 independent serial communication channels, each channel can be flexibly configured as RS-232C or RS-485 interface via jumpers and software. RS-232C is suitable for short-distance point-to-point connections (e.g., local printers, barcode scanners), while RS-485 supports long-distance (up to 1200 meters) and multi-point (up to 32 nodes) bus topology connections, adapting to different scenario requirements.

Full-protocol Adaptation and Mode Switching: Supports Modbus RTU (configurable as master/slave) and ASCII protocols. Modbus RTU enables data interaction where the master polls slaves and slaves respond to host requests. The ASCII protocol supports custom character formats, adapting to dedicated devices without standard protocols. Each channel supports full-duplex (RS-232) / half-duplex (RS-485) mode switching, with adjustable baud rate ranging from 300 bps to 115.2 kbps, featuring flexible parameter configuration.

Industrial-grade Isolation and Anti-interference: Electrical isolation design is adopted between channels and between channels and the backplane, effectively blocking ground loop interference and improving communication stability in strong electromagnetic environments. Compliant with industrial EMC standards, it can resist interference such as voltage fluctuations and electromagnetic radiation, prevent equipment damage caused by common-mode voltage, and ensure data transmission integrity.

Seamless Integration and Easy Installation: Specifically designed for the AC 800M controller, it can be directly inserted into the expansion rack, powered and communicated via the backplane bus without additional external power supply, facilitating easy installation and saving cabinet space. It supports seamless adaptation with Control Builder M software, enabling convenient parameter configuration, program debugging and status monitoring.

- Comprehensive Diagnostics and High Reliability: Equipped with real-time diagnostic functions, it can monitor bus status, slave connection status and communication errors, and upload detailed diagnostic information to the control system, helping operation and maintenance personnel quickly locate faults. Adopting a robust structural package, it is suitable for harsh industrial environments such as wide temperature and high humidity, with a long service life.

III. Technical Parameters

| Parameter Name | Specification |

|---|---|

| Product Model | ABB SC510 3BSE003832R1 |

| Product Type | 4-channel asynchronous serial communication module (dedicated expansion for AC 800M controller) |

| Compatible Systems | ABB AC 800M, 800xA, Symphony®Plus DCS systems |

| Communication Parameters | Protocols: Modbus RTU (Master/Slave), ASCII; Baud rate: 300-115200 bps; Data bits: 7/8 bits; Stop bits: 1/2 bits; Parity bits: None/Odd/Even |

| Interface Configuration | 4 independent channels, each configurable as RS-232C/RS-485, supporting full-duplex/half-duplex switching |

| Power Supply Method | Powered by AC 800M controller backplane bus, power consumption approx. 5W |

| Isolation Performance | Electrical isolation between channels and between channels and backplane, isolation voltage 1500V AC |

| Installation Method | Inserted into AC 800M expansion rack (compatible with DIN rail mounting scenarios) |

| Dimensions | Approx. 120mm (H) × 45mm (W) × 115mm (D) |

| Product Weight | Approx. 0.4kg |

| Operating Environment | Temperature: -25℃~70℃, Relative humidity: 5%~95% (non-condensing), Protection class: IP20 |

| Compliance Certification | Compliant with CE, UL standards |

IV. Working Principle

The core working principle of the ABB SC510 3BSE003832R1 module is a closed-loop communication process of interface adaptation - protocol conversion - data routing - status feedback. Through collaboration with the AC 800M controller, it realizes bidirectional data interaction between serial devices and the DCS system. The specific working process can be divided into four core stages:

According to the type of field devices, configure the interface type (RS-232C/RS-485), communication protocol (Modbus RTU/ASCII), baud rate, parity bit and other parameters of each channel via jumpers and Control Builder M software, establishing the communication adaptation foundation between the module and field devices.

The module receives data sent by field devices through serial channels, converts it into logical data recognizable by the controller via the internal protocol parsing unit, and then transmits it to the AC 800M main CPU at high speed through the backplane bus to complete field data collection. In Modbus master mode, the module periodically polls slave devices to actively collect process data.

Control commands generated by the main CPU are transmitted to the module via the backplane bus. The module converts logical commands into corresponding serial protocol formats (Modbus RTU/ASCII) and issues them to field devices through designated channels, realizing remote control of external devices. Meanwhile, the electrical isolation circuit ensures the safety of command transmission and avoids interference effects.

V. Common Fault Troubleshooting

1. Communication Interruption, No Data Transmission

2. Data Transmission Errors, Garbled Code or Packet Loss

3. Module Fails to Interconnect with AC 800M Controller