Description

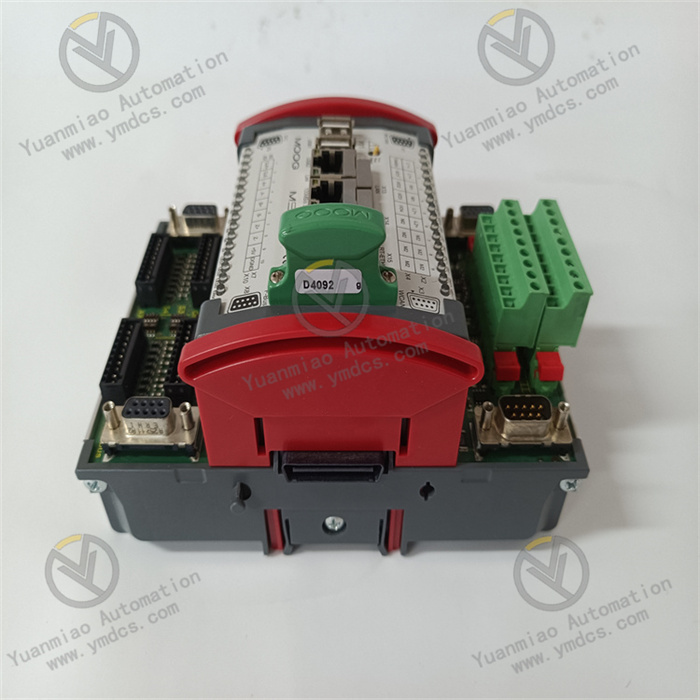

Functional Features Triple Design: Adopting a Triple Module Redundancy (TMR) structure, the controller, I/O module, and communication are all triplicated, which can simultaneously meet the requirements of high reliability and high availability for fault-tolerant control. The system can identify faulty components and automatically eliminate them, allowing for online repair of faulty components without interrupting the process operation. Precise Control: Based on the TMR structure, hardware voters are used to process input and output signals, or intermediate values are selected for processing, ensuring precise control and preventing the system from failing due to a single-point fault. Powerful Diagnostic Function: Each independent sub-circuit, module, and functional circuit is diagnosed. Operational errors are monitored and reported, and all diagnostic information is stored, which can be used by programmers to modify the controller execution or conduct process maintenance. Intelligent I/O Module: The I/O module has intelligent functions. Its microprocessor can filter and repair inputs, diagnose hardware faults, provide information for output data voting, check the validity of output status, and diagnose field line problems, reducing the workload of the main processor.

Technical Parameters Operating Voltage: Usually 220V. Program Capacity and Data Capacity: The program capacity may be 5MB, and the data capacity may be 3MB. Processing Speed: The processing speed is in standard Hz, and the specific value may vary according to the product specifications. Product Certification: Certifications such as UE indicate that it complies with relevant safety and quality standards.

Application Areas Oil and Gas: Suitable for various links such as oil and gas extraction, transportation, and processing. It can provide reliable control and monitoring of key equipment in harsh industrial environments, ensuring the safety and efficiency of production. Power Industry: It can be used for the control and monitoring of key equipment in the power production, transmission, and distribution processes, ensuring the stable operation of the power system. Chemical Industry: It can meet the requirements of high-reliability control in chemical production, precisely controlling and monitoring key parameters in the production process to ensure production safety and product quality.

Common Faults and Solutions

Communication Faults

Reasons: Damaged communication cables, loose interfaces, incorrect parameter settings, or communication module failures, etc.

Solutions: Check the connection of the cables and whether they are damaged, and replace the damaged cables; check the interfaces and re-plug them; confirm the communication parameters and re-set the correct parameters; use professional equipment to detect the communication module and replace it if there are faults.

I/O Module Faults

Reasons: Hardware faults of the module, sensor or actuator failures, incorrect wiring, etc.

Solutions: Check whether the module has phenomena such as overheating and damage, and replace the faulty module; check the sensors and actuators and replace the faulty devices; check the wiring and repair the errors.

System Diagnostic Faults

Reasons: Abnormal diagnostic functions may be caused by system software problems, hardware faults, or external interference, etc.

Solutions: Check whether the system software is the latest version, and update or repair it if necessary; use professional detection tools to comprehensively detect the hardware and replace the faulty hardware; investigate external interference sources and take shielding or isolation measures.