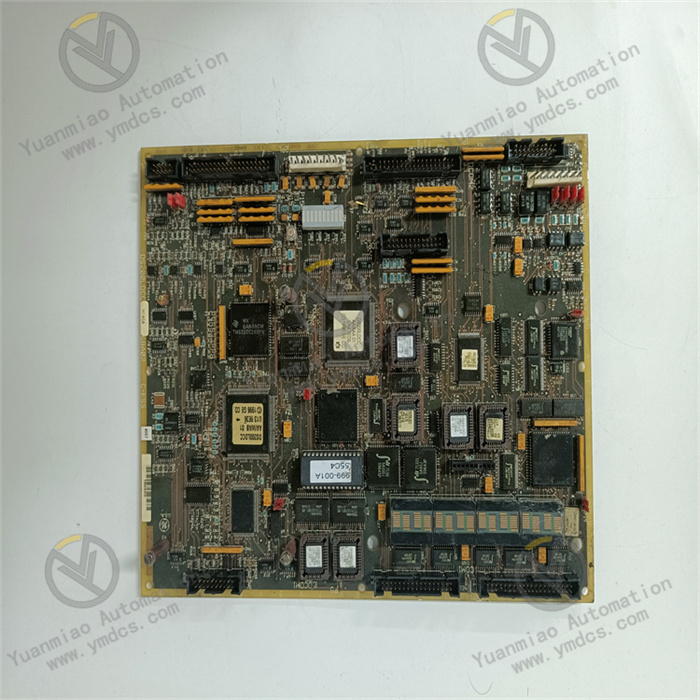

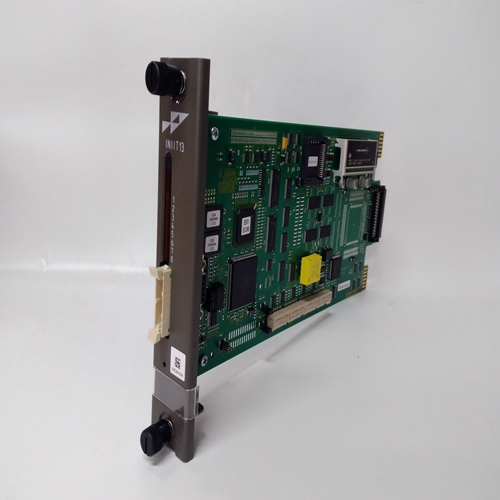

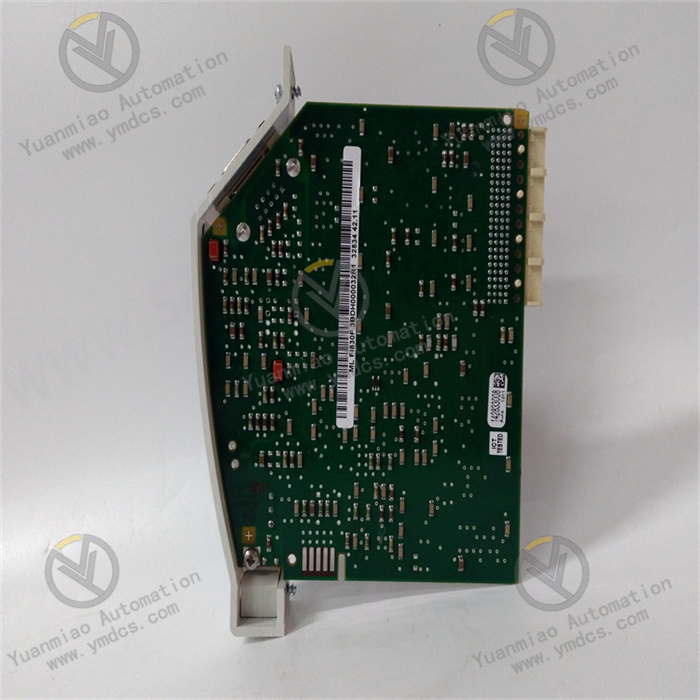

Description

ABB FI810F 3BDH000030R1

Technical Specifications Basic Function: As an analog input module, it is mainly used to convert various analog signals in the industrial field (such as signals from sensors for temperature, pressure, flow rate, liquid level, etc.) into digital signals, and transmit them to the control system for processing and analysis, so as to achieve the monitoring and control of industrial processes. Input Channels: It usually has multiple analog input channels (the specific number may vary depending on the product configuration), and can collect multiple analog signals simultaneously, improving the efficiency and real-time performance of data collection. Input Signal Types: It supports multiple types of analog input signals. Common ones include 4-20mA current signals, 0-10V voltage signals, thermocouple signals (such as Type K, Type J, Type T, etc.), and resistance temperature detector (RTD) signals (such as Pt100, Cu50, etc.), which can adapt to the output signals of different types of sensors. Accuracy and Resolution: It has high measurement accuracy and resolution, and can accurately collect and convert analog signals. For example, the measurement accuracy of a 4-20mA current signal may reach ±0.1% FS (Full Scale), and the resolution may be 16 bits, meeting the requirements for precise measurement in industrial production. Communication Interfaces: It can communicate with the control system through fieldbuses (such as Profibus DP, Modbus RTU, etc.) to achieve rapid data transmission and exchange. The specific communication protocols and interface types supported may vary according to different product versions and configurations. Operating Power Supply: Generally, it requires a stable DC power supply. The common supply voltage is 24V DC, and it has a certain ability to resist power fluctuations to ensure the stable operation of the module in an industrial environment. Operating Temperature and Humidity Range: The operating temperature range is usually around -20°C to +60°C, and the relative humidity range is 5% - 95% (non-condensing), which can adapt to relatively harsh industrial environmental conditions. However, additional protective measures may be required in extreme environments.

Features and Advantages High-precision Measurement: By adopting advanced signal processing technology and high-precision A/D conversion chips, it can achieve high-precision collection and conversion of analog signals, providing reliable data support for the precise control of industrial processes. Strong Flexibility: It supports multiple types of analog input signals and communication protocols, and can be flexibly connected and integrated with different types of sensors and control systems to meet the needs of different industrial applications. High Reliability: As a well-known industrial automation brand, ABB's products have undergone strict testing and verification. With the use of high-quality electronic components and a sturdy housing design, they have good anti-interference ability and environmental adaptability, and can operate stably in complex industrial environments, reducing the probability of failures. Easy Maintenance: The module adopts a modular design, which is convenient for installation and disassembly, and facilitates daily maintenance and inspection. At the same time, it has a self-diagnosis function, which can promptly detect module failures and provide corresponding alarm information, reducing maintenance costs and downtime.

Application Areas Petrochemical Industry: In the processes of oil refining and chemical production, etc., it is used to collect various process parameters (such as temperature, pressure, flow rate, liquid level, etc.) to achieve real-time monitoring and control of the production process, ensure the safety and stability of the production process, and improve product quality and output. Power Industry: It can be used for the control of boilers, steam turbines, generators, etc. in power plants, and accurately measure and collect parameters such as temperature, pressure, water level, and rotational speed, providing data support for the automated control and fault diagnosis of power production. Metallurgical Industry: In the steel production process, it monitors and controls parameters such as the temperature, pressure, charge flow rate of the blast furnace, and the speed and tension of the steel rolling production line, improving production efficiency and product quality, and reducing energy consumption. Mechanical Manufacturing: It is used for the testing of mechanical equipment and quality control in the production process. By collecting and analyzing various parameters (such as vibration, displacement, temperature, etc.) during the operation of the equipment, it optimizes the design and performance of the equipment to ensure that the products meet the quality standards. Food and Beverage Industry: In the processes of food processing and beverage production, it monitors and controls parameters such as temperature, pressure, liquid level, and flow rate to ensure product quality and hygiene standards, and achieve an automated production process.

Common Faults and Solutions 1. Abnormal Input Signal Possible Causes: Sensor faults (such as sensor damage, drift, etc.), signal transmission cable faults (such as open circuit, short circuit, interference, etc.), faults in the internal signal processing circuit of the module, parameter setting errors (such as incorrect range setting). Solutions: Check whether the sensor is working properly. A standard signal source can be used to calibrate the sensor or replace the faulty sensor; Check the signal transmission cable to ensure a firm connection, no damage, and no interference. Replace the cable if necessary; Check the internal circuit of the module. If there is a fault, contact professional maintenance personnel for repair; Check the parameter settings to ensure that parameters such as the range are consistent with the actual measurement requirements. 2. Communication Fault Possible Causes: Poor connection of the communication cable, damage to the communication interface, incorrect setting of the communication protocol, network faults (such as network interruption, IP address conflict, etc.). Solutions: Check whether the connection of the communication cable is firm and whether there is any damage; Check the communication interface and replace it in time if it is damaged; Confirm that the communication protocol settings are consistent with those of other devices, such as baud rate, data bits, stop bits, etc.; Check the network connection to ensure the normal operation of the network and solve problems such as IP address conflicts. 3. Module Fault Indicator Light On Possible Causes: Internal hardware faults of the module (such as chip damage, power supply faults, etc.), software errors (such as program errors, configuration errors, etc.). Solutions: Obtain detailed fault information through the diagnostic function of the module or relevant software, and troubleshoot and repair according to the fault prompts. If it is a hardware fault, contact professional maintenance personnel for repair or replace the module; If it is a software error, reconfigure or update the software. 4. Inaccurate Measurement Value Possible Causes: Decrease in the module's accuracy, zero drift, incorrect gain setting, etc. Solutions: Calibrate the module. High-precision calibration equipment can be used for zero and gain calibration; Check the setting parameters of the module to ensure that parameters such as the gain are set correctly; If the module's accuracy decreases significantly, it may be necessary to replace the module.

ABB Related Products

| FI810F 3BDH000030R1 | EI802F 3BDH000016R1 |

| FI820F 3BDH000031R1 | EI813F 3BDH000022R1 |

| FI830F 3BDH000032R1 | EI803F 3BDH000017R1 |

| FI840F 3BDH000033R1 | EI811F 3BDH000020R1 |

| SD823 3BSC610039R1 | SD524 1SAP240000R0001 |

| SD831 3BSC610064R1 | SD812 3BSC610023R0001 |

| SD832 3BSC610065R1 | SD811 3BSC610022R0001 |

| SD833 3BSC610066R1 | SD802F 3BDH000012R1 |

| SD834 3BSC610067R1 | SD812F 3BDH000014R1 |

Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage