Description

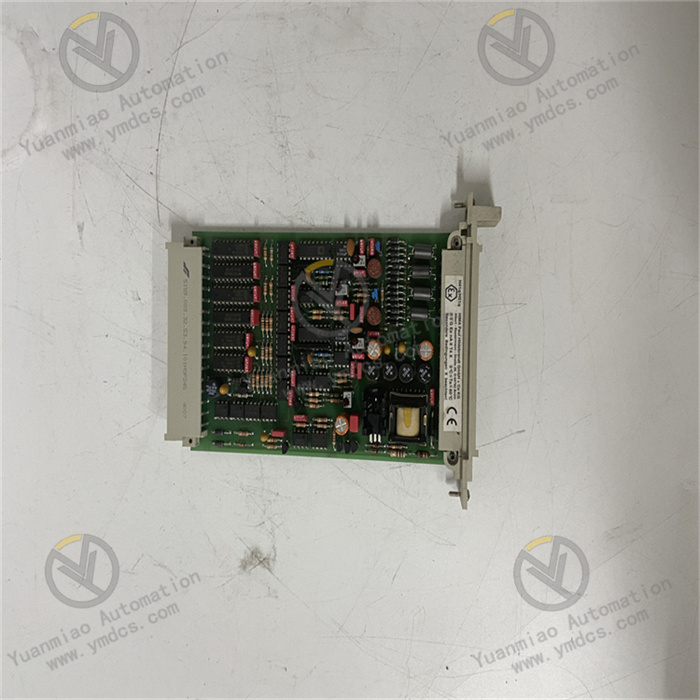

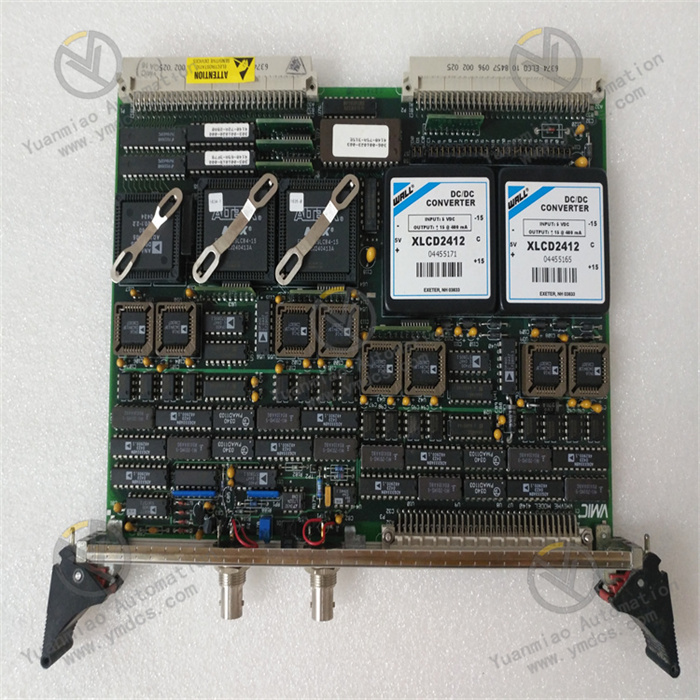

Product Overview The Abaco Systems VMIVME - 017807 - 413000/350 - 0001007807 - 413000 D is a board based on the VME bus architecture. The VME bus has the ability of high-speed and reliable data transmission and is widely applied in fields with high requirements for reliability and real-time performance, such as industrial automation, aerospace, and national defense. Functional Features High-performance Processing Capability: It may be equipped with a high-performance processor or logic chip, which can quickly process various data and instructions to meet the requirements of complex computing tasks. For example, in an industrial automation control system, it can perform real-time analysis and processing of a large amount of sensor data to achieve precise control and monitoring. Rich Interface Types: It is equipped with a variety of interfaces, such as digital input and output interfaces, analog input and output interfaces, serial ports, network ports, etc. These interfaces can be conveniently connected to various external devices to achieve data collection, transmission, and control. For instance, digital input and output interfaces can be used to connect discrete quantity devices in an industrial field, and analog input interfaces can be used to collect analog signals from sensors. High-reliability Design: In view of the particularity of its application fields, redundant design, anti-interference measures, and high-quality electronic components are usually adopted. It can operate stably in harsh industrial environments or complex electromagnetic environments to ensure the reliability and stability of the system. For example, in the aerospace field, it can ensure the normal operation of the equipment even under conditions of high vibration and strong electromagnetic interference. Real-time Operating System Support: It supports a real-time operating system and can meet application scenarios with extremely high requirements for real-time performance. In industrial control, it can precisely control the execution time of tasks to ensure the real-time response performance of the system and avoid production accidents or system failures caused by task delays.

Technical Parameters Processor Performance: The specific processor model and performance parameters depend on the product version. Generally, it has a relatively high main frequency and processing capability. For example, it may adopt a processor with a main frequency of [X] MHz and has a processing speed of [X] MIPS (millions of instructions per second), which can quickly process various data and instructions. Memory Capacity: It is usually equipped with a certain amount of memory, such as [X] MB of DDR memory, which is used for data temporary storage and processing to support the efficient operation of the system. A larger memory capacity can ensure that the system will not run out of memory when processing a large amount of data. Interface Types and Quantities: There may be [X] digital input and output interfaces, which can be used to connect various digital signal devices; there may be [X] analog input interfaces, which support the collection of analog signals with [specific resolution]; there may be [X] serial ports, which support different baud rates; there may be [X] network ports, which support [specific network protocols and rates]. Operating Temperature Range: It can generally work within a relatively wide temperature range, such as from - 40°C to 85°C, to adapt to different industrial environments and application scenarios. It can maintain stable performance in high or low temperature environments. Power Requirements: It usually requires a stable DC power supply, such as + 5V, +12V, etc., and has a certain ability to suppress power supply ripple to ensure that the device can operate normally under different power supply conditions.

Operation Guide: Preparation Before Operation 1. Hardware Installation Ensure that the VME bus chassis of the target system is powered off and is in a safe operating environment. Carefully insert the VMIVME - 017807 - 413000/350 - 0001007807 - 413000 D board into the VME bus slot, ensuring that the board is tightly connected to the slot and the installation position is correct. Connect relevant external devices, such as sensors, cables, etc., and make correct physical connections according to the functional requirements of the device. Ensure that all connections are firm to avoid signal transmission problems caused by looseness. 2. Software Installation and Configuration Install the driver and related software tools supporting the board on the host system. Usually, these software can be obtained from the official website of Abaco Systems or found on the CD provided with the board. Complete the software installation process according to the prompts of the installation wizard. Note that the computer may need to be restarted during the installation process. After the installation is completed, open the configuration software. Configure the parameters of the board according to the actual application requirements, such as setting the acquisition channels, sampling frequency, data transmission mode, communication protocol, etc. Refer to the technical manual and related documents of the device during the configuration process to ensure that the parameter settings are correct.

Basic Operations 1. Data Acquisition (if the device has this function) After configuring the acquisition parameters, start the data acquisition task. You can trigger the acquisition process through the corresponding buttons or commands on the software interface. Observe the real-time data display on the software interface to check whether the collected data is normal. If the data is abnormal, check the sensor connection, acquisition parameter settings, and the normal operation of the board hardware. You can set the data storage path and format as needed, and save the collected data to the specified location for subsequent analysis and processing. 2. Data Processing and Analysis (if the device has this function) Use the data processing tools provided by the software supporting the board to analyze and process the collected data. For example, operations such as filtering, amplification, and calculation of statistical parameters can be performed. Write custom data analysis algorithms or scripts according to specific application requirements, and call the computing resources of the board through the software interface to execute data processing tasks. During the processing, pay attention to whether the processing results meet the expectations. If there are errors or abnormalities, check whether the algorithm logic, data format, and the computing capability of the board meet the requirements. 3. Communication Function Operation (if the device has this function) Configure the communication parameters, including the address of the target device, communication protocol, baud rate, etc. Ensure that the parameter settings are consistent with those of the communication peer device to establish a reliable communication connection. When sending data, enter the data content to be sent in the software interface and select the send command. Monitor the sending process and check for sending errors or timeouts, etc. If there are problems, check whether the communication link, device connection, and parameter settings are correct. When receiving data, start the receiving thread or process and wait to receive data from other devices. After receiving the data, analyze and process the data, and extract useful information according to the communication protocol and application requirements.

Device Monitoring and Maintenance

1. Status Monitoring

View the operating status of the board in real time through the status indicator lights or monitoring window on the software interface. This includes information such as the power status, data transmission status, and device operating status.

Regularly check the hardware status of the board, such as the temperature and the operation of the fan. If the temperature of the board is too high or the fan fails, take timely measures for heat dissipation or repair to avoid device damage.

2. Fault Troubleshooting and Handling

If the device malfunctions, first check the error prompt information on the software interface and initially determine the cause of the fault according to the prompt information. At the same time, refer to the fault troubleshooting section in the technical manual of the device for further troubleshooting.

Check whether the hardware connection is loose, whether the cable is damaged, and whether the power supply is normal, etc. For some common hardware problems, you can try to re-plug the board, replace the cable, or check the power adapter, etc.

If the fault still exists, contact the technical support personnel of Abaco Systems and describe the fault phenomenon, the configuration information of the device, and the operation steps in detail so that they can perform remote diagnosis or provide further repair suggestions.