Description

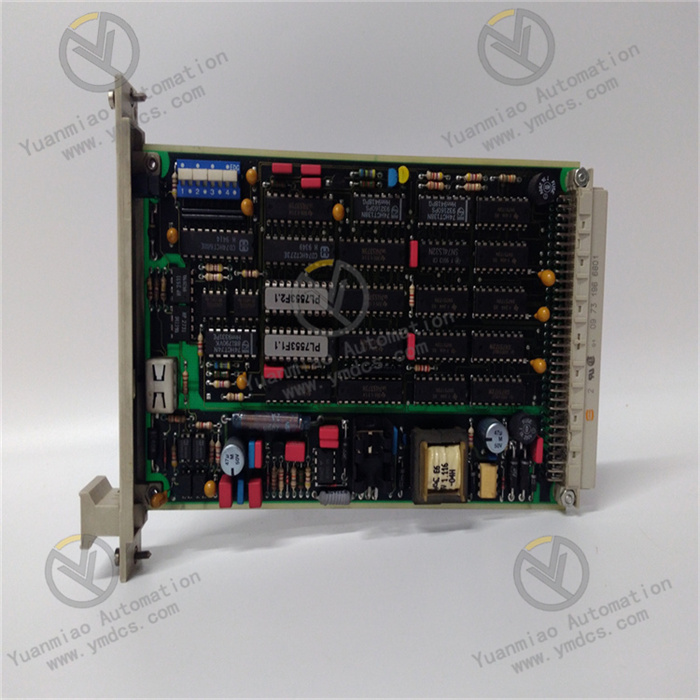

ABB BC810 3BSE030230R1

I. Overview

The ABB BC810 3BSE030230R1 is a dedicated bus interconnection unit, with its core positioning as a specialized communication interconnection component for the CEX bus. Designed specifically for high-speed data interaction between internal devices of Distributed Control Systems (DCS), the core function of this unit is to establish a CEX bus communication link, realize stable data transmission and communication coordination between nodes such as controllers, I/O modules and terminal devices. It is a key core component for the Advant 800xA system to build a redundant communication architecture and ensure global data interconnection.

II. Product Features

Exclusive Interconnection Design for CEX Bus: Tailor-made for the ABB CEX bus architecture, it precisely adapts to the communication protocol of the Advant 800xA system, can efficiently establish bus communication links, realize high-speed data interaction between node devices, ensure the integrity and real-time performance of data transmission, and provide communication support for global system control.

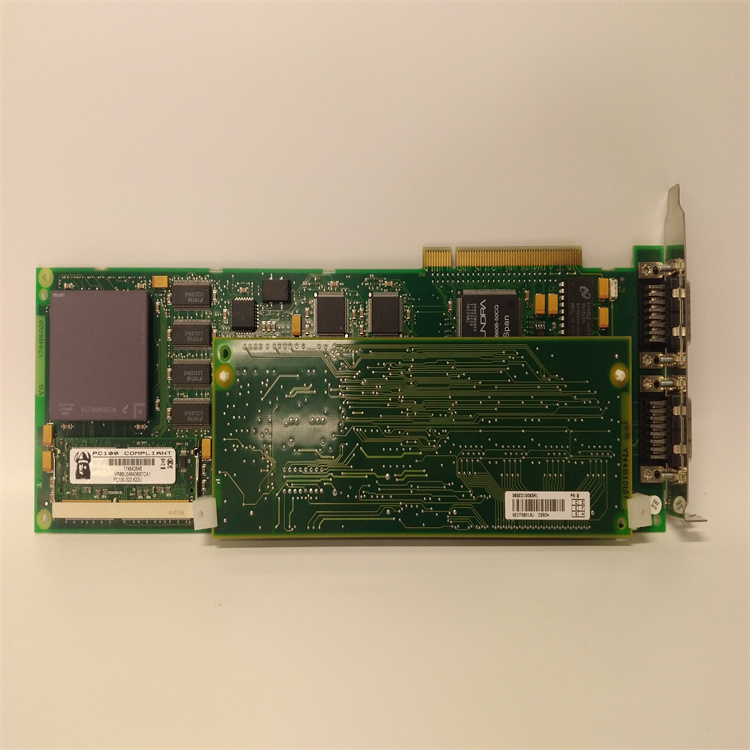

Standardized Kit Combination Adaptability: It can be combined with the TP 857 backplane (60mm in width) and TB 850 CEX bus terminator to form a complete BC810K01 kit. The backplane integrates CEX bus connectors and external power interfaces, and the terminator ensures stable bus signals. The kit-based design simplifies system integration and deployment processes, improving installation efficiency.

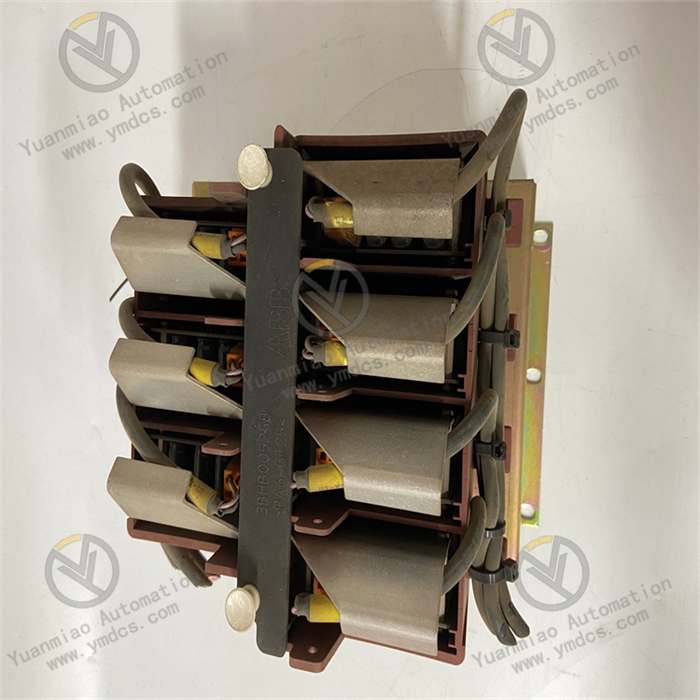

Redundant Communication and High Reliability: It supports the configuration of redundant communication interface units and can build a dual-link redundant communication architecture, effectively avoiding communication interruption caused by single-link faults and ensuring continuous system operation. Equipped with external power supply voting diodes and fuses, it enhances power supply stability and further improves equipment operation reliability.

Hot-swapping and Online Maintenance Support: It supports hot-swapping function and online CPU replacement. In redundant system configuration (dual BC810 interconnection + master-slave CPU), the CPU backplane can be replaced online without interfering with CEX bus communication traffic, minimizing maintenance downtime and ensuring production continuity.

Compact Structure and Convenient Installation: Adopting a miniaturized and compact design, with dimensions of 10.2cm (length) × 7.6cm (width) × 12.7cm (height) and a weight of only about 0.2kg, it occupies small space and is suitable for narrow installation environments. The backplane is grounded with 35mm DIN rail through the metal parts of the housing, ensuring firm installation and enhanced anti-interference capability.

- Strong Environmental Adaptability and Anti-interference: Using industrial-grade components and protective design, it can withstand complex working conditions such as electromagnetic interference and temperature fluctuations in industrial sites, and can operate stably in harsh industrial environments. It is suitable for scenarios with extremely high equipment reliability requirements such as wind power and nuclear power.

III. Technical Parameters

1. Core Basic Parameters

- Product Model: ABB BC810 3BSE030230R1

- Product Type: Industrial-grade CEX Bus Interconnection Unit

- Brand Series: ABB Advant 800xA Series

- Core Functions: CEX bus link establishment, high-speed data transmission, redundant communication support, hot-swapping, online CPU replacement

- Compatible System: ABB Advant 800xA Distributed Control System

- Kit Combination: Can form the BC810K01 kit (including BC810 unit, TP857 backplane, TB850 terminator; kit model number 3BSE031154R1)

- Safety Protection: External power supply voting diodes, fuse protection

- Application Fields: Industrial automation fields such as wind power, hydropower, nuclear power, petrochemical industry, metallurgy, intelligent manufacturing, etc.

2. Electrical Performance Parameters

- Power Supply Method: External power supply

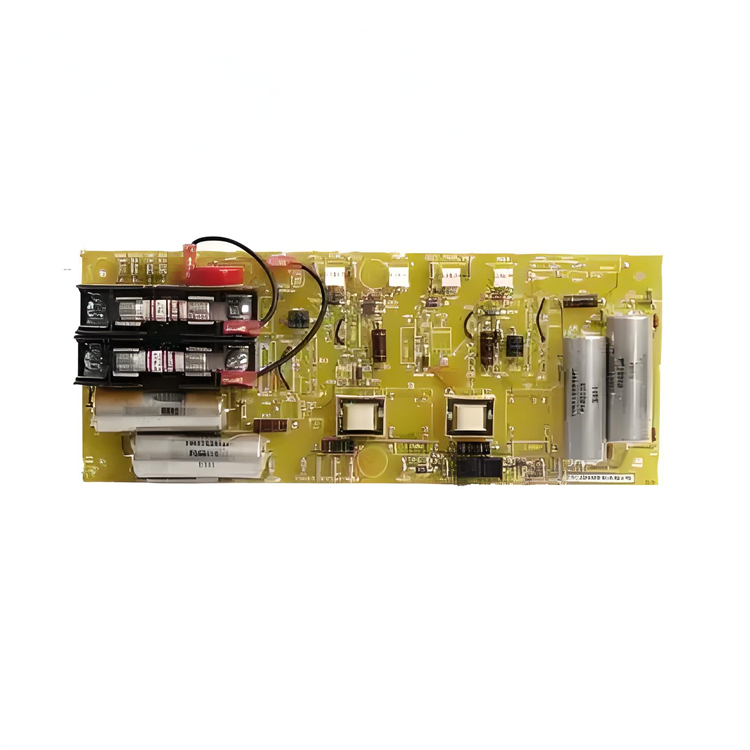

- Core Circuit: Integrated +3.3V voltage converter, CEX bus drive logic circuit

- Communication Interface: Specialized CEX bus connector (connected via TP857 backplane)

- Communication Characteristics: Supports redundant communication links to ensure data transmission continuity

- Protection Functions: Power circuit fuse protection, reverse power supply protection

- Grounding Method: Grounded with DIN rail through the metal parts of the backplane to enhance anti-interference capability

3. Environmental and Physical Parameters

- Operating Temperature: -25℃ ~ +60℃ (industrial standard working conditions)

- Storage Temperature: -40℃ ~ +85℃

- Relative Humidity: 5% ~ 95% RH (non-condensing)

- Dimensions: 10.2cm (length) × 7.6cm (width) × 12.7cm (height)

- Weight: Approximately 0.2 kg

- Mounting Method: 35mm DIN rail mounting (fixed via TP857 backplane)

- Vibration Resistance: Complies with industrial-grade vibration standards, adapted to on-site vibration environments

IV. Working Principle

The core working principle of the ABB BC810 3BSE030230R1 bus interconnection unit is a closed-loop communication process of bus link establishment - data transceiving and conversion - redundant coordination - status monitoring. Through the coordinated operation of the voltage conversion module, CEX bus drive module and redundant control module, it realizes high-speed and stable communication between nodes in the Advant 800xA system. The specific working process can be divided into four core stages:

Stage 1: Link Establishment StageThe BC810 unit is connected to the system bus through the CEX bus connector of the TP857 backplane, and the TB850 terminators are connected to both ends of the bus to stabilize bus signals and suppress signal reflection. The three components are combined to build a complete CEX bus communication link. External power supply is connected to the unit through the backplane, converted into internal working voltage by the +3.3V voltage converter to supply power to the drive logic and communication circuits. Meanwhile, fuses and voting diodes ensure power supply safety.

Stage 2: Data Conversion and Transmission StageThe internal drive module of the unit receives data signals sent by node devices (controllers, I/O modules), performs logic conversion and amplification processing to adapt to the CEX bus transmission protocol, and accurately transmits data to target nodes through the bus link. At the same time, it receives transmission data from other nodes, converts them into signals recognizable by devices and feeds them back to corresponding nodes, realizing two-way data interaction.

Stage 3: Redundant Coordination StageIn redundant configuration scenarios, dual BC810 units work in interconnection, synchronizing communication status in real time. When the main link is normal, the master unit is responsible for data transmission. When the main link fails, the standby unit immediately switches to take over the communication task, ensuring uninterrupted data transmission and avoiding system operation impact caused by communication interruption. It also supports online switching of master-slave CPUs, and the switching process does not interfere with bus traffic.

V. Common Fault Troubleshooting

1. Bus Communication Interruption, No Data Transmission

- Detect the external power supply voltage to ensure stable power supply, check whether the fuse is blown. If blown, replace it with a fuse of the same specification and troubleshoot the cause of power supply failure.

- Disconnect the power supply, re-plug the connection between the BC810 unit and the backplane, clean the oxide layer of the contact pins to ensure reliable contact.

- Check the installation position of the TB850 terminator (both ends of the bus), test the continuity of the terminator, replace it if damaged, and ensure signal stability.

- Check the bus line connection, re-tighten the connectors, repair damaged lines, use a multimeter to detect whether the lines are short-circuited, and eliminate short-circuit faults.

- In redundant configuration, restart the dual BC810 units to re-synchronize the coordination status. If the abnormality persists, switch to single-unit working mode and troubleshoot the faulty unit.

2. Failure to Restore Communication After Unit Hot-swapping

- Re-plug the unit according to the standard process: first cut off the unit power supply, pull out the unit, check whether the pins are worn or oxidized, clean the oxide layer and reinsert it to ensure tight contact with the backplane, then restore power supply.

- Check whether the backplane connector is deformed or damaged, replace the TP857 backplane if damaged.

- Replace with a standby BC810 unit for testing. If the standby unit can communicate normally, it is determined that the internal circuit of the original unit is damaged. Contact ABB official after-sales service for maintenance or replacement.

- Refresh the unit configuration information through the upper system and restart the bus communication link to ensure the system identifies the unit.

3. Redundant Switching Failure, Communication Interruption During Faults

- Verify the redundant configuration parameters of dual units through configuration software to ensure consistent parameters, restart the units after reconfiguration, and synchronize the coordination status.

- Detect the working status of the standby unit, test the communication function of the standby unit separately, replace the standby unit if faulty.

- Check the connection of redundant communication link connectors, re-tighten them, repair damaged lines, and ensure smooth links.

- Restart the dual units and upper controller, reset the coordination synchronization mechanism to ensure rapid switching in case of faults.